Biological drying treatment method for organic solid waste

A technology of organic solids and biological drying, applied in the direction of microbial treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of poor applicability, large floor area, high energy consumption of drying, and achieve suitability Wide range, saving energy consumption and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) The domestic sludge is taken from the desliming workshop of a domestic sewage treatment plant in a county in Hubei Province. After being dehydrated by a high-pressure plate and frame, it is pulverized to less than 20mm, with a moisture content of 70%, a pH value of 7.23, and an organic matter content of 43.2%;

[0034](2) adding a bulking agent to the domestic sludge to obtain the first mixed material, the water content of the first mixed material is 65%, the carbon-nitrogen ratio is 30:1, and the pH value is 7.3; %) as a bulking agent, the addition ratio is 10wt% of the chemical sludge;

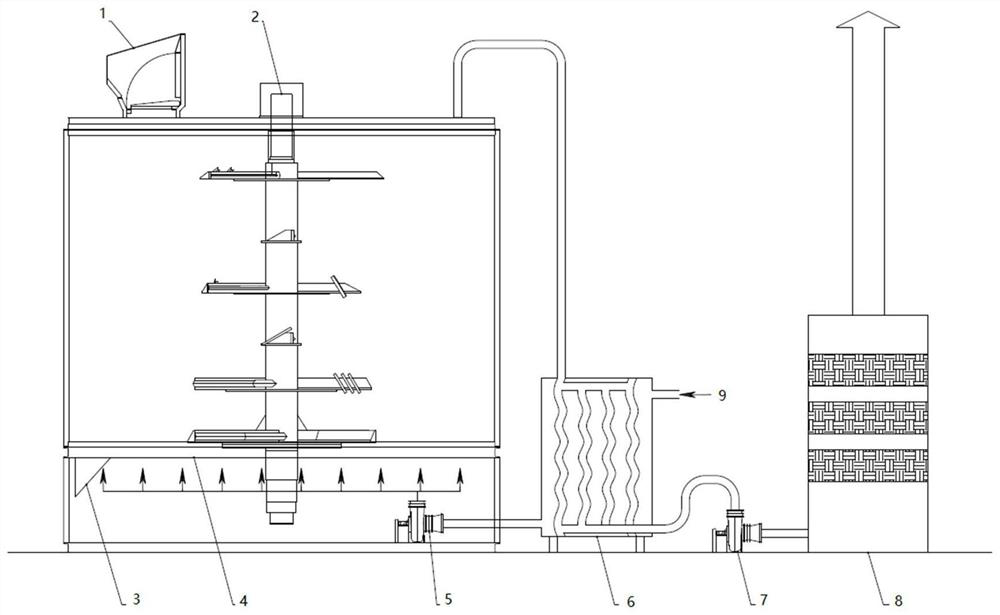

[0035] (3) Continue to add a microbial inoculum (Pichia pastoris 2.0×10 with a fresh weight of 1wt‰ of the mixture) 9 cfu / mL, Lactobacillus plantarum 3.5×10 9 cfu / mL, Geotrichum candidum 5.0×10 3 cfu / mL, Aspergillus grisea 1.0×10 4 cfu / mL) after stirring evenly, place it in such as figure 1 Biodrying takes place in the biodrying reactor 4 of the closed biodrying reactor system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com