Novel root-puncture-resistant modified asphalt waterproof coiled material and preparation method thereof

A technology for modified asphalt and waterproofing membranes, which is applied to roofing, shaft equipment, mining equipment and other directions using flexible materials, can solve the problems of root resistance and shortened service life, poor waterproof performance, and low tensile strength. Improve the scope of application and service life, excellent aging resistance, and improve the effect of high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

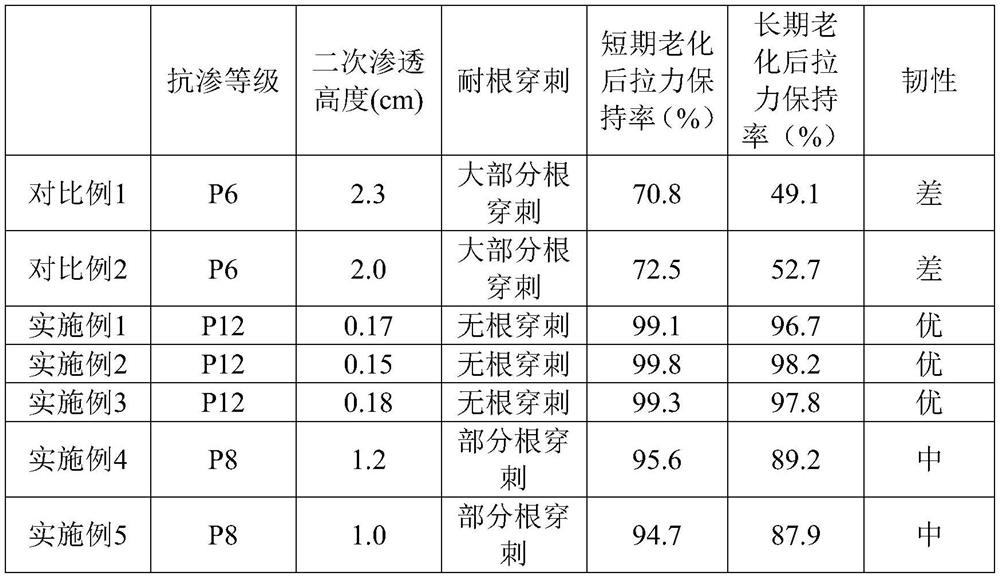

Examples

Embodiment 1

[0038] (1) Get 10 parts by weight of phenolic resin and 0.6 parts by weight of acrylic monomers and mix them in a container, stir at a high speed and be heated to 80 ° C, then add 4 parts by weight of trimethylolpropane, under the action of mechanical force and heat, Continue to mix in a mixer for 40 min, and then cool to normal temperature to obtain a trimethylolpropane-phenolic resin block copolymer.

[0039](2) after soaking 150 parts by weight of waste rubber powder in aluminum sulfate solution for 24 hours, washing by filtration, then adding 15 parts by weight of trimethylolpropane-phenolic resin block copolymer and 200 parts by weight of acetone in step (1) , magnetic stirring for 1h, mixed evenly, and then placed in an oven to dry completely to obtain modified waste rubber powder.

[0040] (3) get 2 parts by weight of diallylamine and put it in 20 parts by weight of organic solvent, fully stir under low temperature condition, until diallylamine dissolves, obtain diallyl...

Embodiment 2

[0045] (1) get 15 parts by weight of phenolic resin and 1.0 parts by weight of acrylic monomer to mix and place in a container, stir at a high speed and be heated to 90 ° C, then add 6 parts by weight of trimethylolpropane, under the action of mechanical force and heat, Continue to mix in a mixer for 60 min, and then cool to normal temperature to obtain a trimethylolpropane-phenolic resin block copolymer.

[0046] (2) After soaking 180 parts by weight of waste rubber powder in aluminum sulfate solution for 30 hours, washing by filtration, then adding 18 parts by weight of trimethylolpropane-phenolic resin block copolymer and 250 parts by weight of acetone in step (1) , magnetic stirring for 1.5h, mixed evenly and then placed in an oven to dry completely to obtain modified waste rubber powder.

[0047] (3) get 4 parts by weight of diallylamine and put it in 30 parts by weight of organic solvent, fully stir under low temperature conditions, until diallylamine dissolves, obtain d...

Embodiment 3

[0052] (1) get 20 parts by weight of phenolic resin and 1.2 parts by weight of acrylic monomers and mix them in a container, stir at a high speed and heat to 100 ° C, then add 8 parts by weight of trimethylolpropane, under the action of mechanical force and heat, Continue to mix in a mixer for 80 min, and then cool to normal temperature to obtain a trimethylolpropane-phenolic resin block copolymer.

[0053] (2) after soaking 200 parts by weight of waste rubber powder in aluminum sulfate solution for 48h, washing by filtration, then adding 20 parts by weight of trimethylolpropane-phenolic resin block copolymer and 300 parts by weight of acetone in step (1) , magnetic stirring for 2h, mixed evenly and dried in an oven to obtain modified waste rubber powder.

[0054] (3) get 5 parts by weight of diallylamine and put it in 50 parts by weight of organic solvent, fully stir under low temperature condition, until diallylamine dissolves, obtain diallylamine acid solution; Add modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com