Lithium metal anode and preparation method thereof

A lithium metal anode and lithium metal technology, applied in the direction of non-metallic elements, chemical instruments and methods, negative electrodes, etc., can solve the problems of low coulombic efficiency, high risk of battery failure, capacity loss, etc., to reduce the current density and strengthen the skeleton , the effect of preventing reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

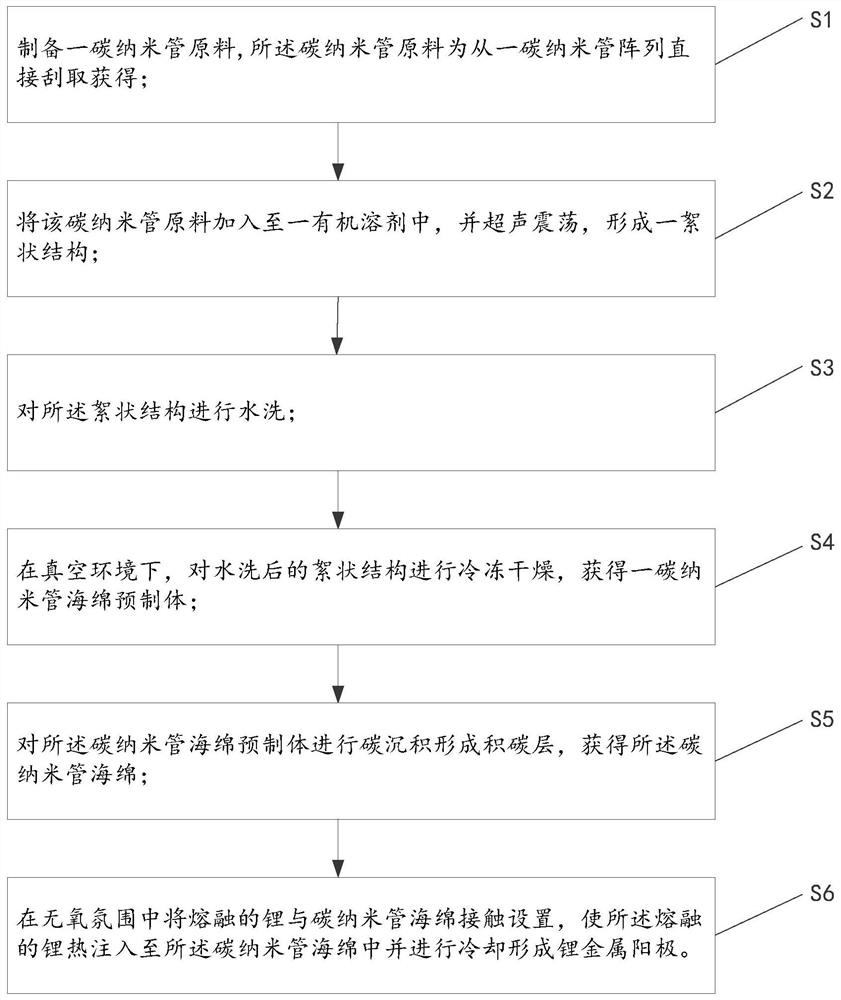

[0056] Please refer to figure 1 , the embodiment of the present invention provides a preparation method of a lithium metal anode, comprising:

[0057] Step 1, preparing a carbon nanotube raw material, the carbon nanotube raw material is obtained by scraping directly from a carbon nanotube array;

[0058] Step 2, adding the carbon nanotube raw material to an organic solvent, and ultrasonically oscillating to form a flocculent structure;

[0059] Step 3, washing the flocculent structure with water;

[0060] Step 4: freeze-drying the washed flocculent structure in a vacuum environment to obtain a carbon nanotube sponge preform;

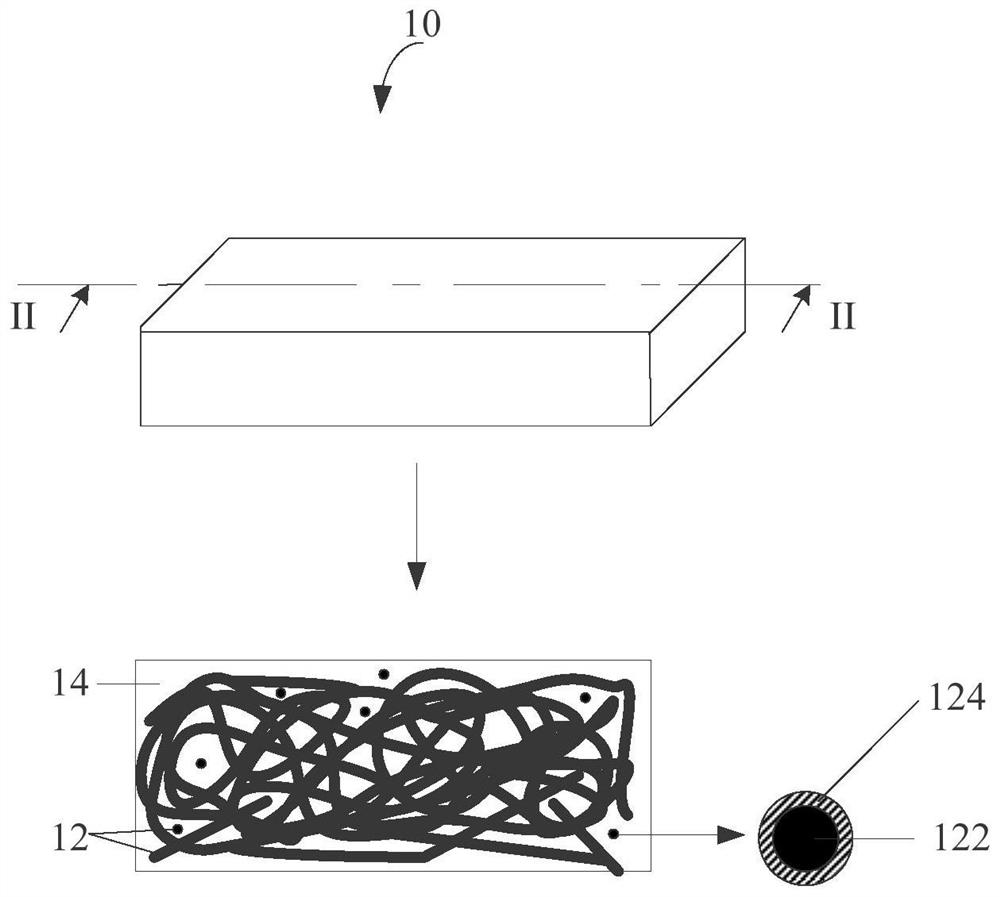

[0061] Step 5, carrying out carbon deposition on the carbon nanotube sponge preform to form a carbon deposit layer to obtain the carbon nanotube sponge;

[0062] In step 6, the molten lithium is placed in contact with the carbon nanotube sponge in an oxygen-free atmosphere, and the molten lithium is thermally injected into the carbon nanotube sponge and...

Embodiment 1

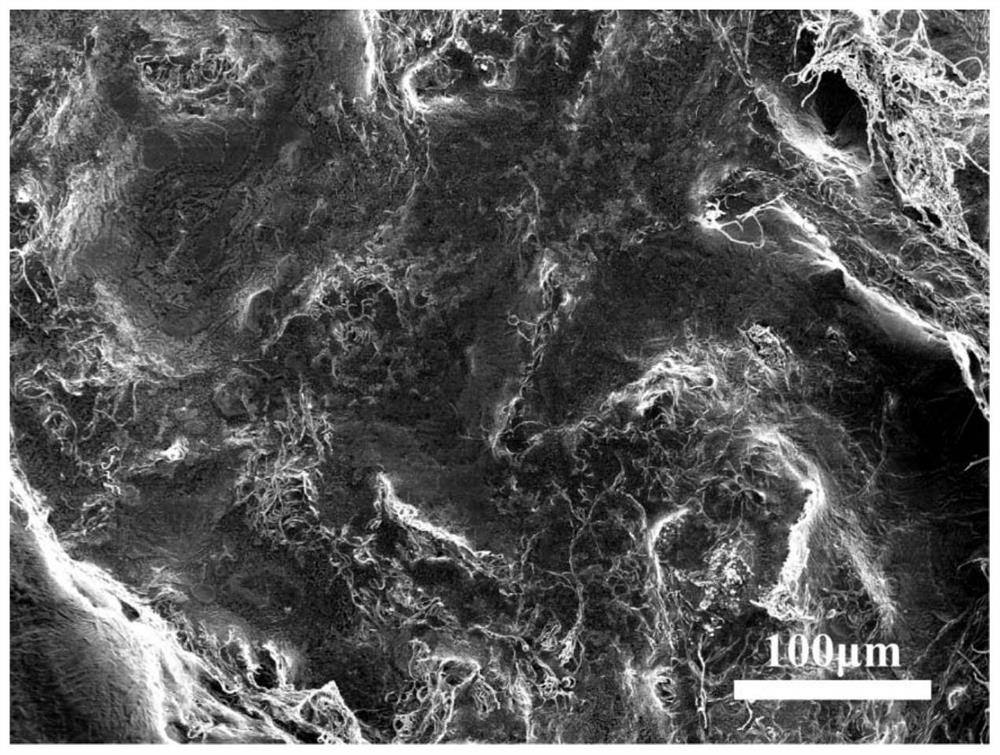

[0088] Provide a super-aligned carbon nanotube array, the carbon nanotubes in the carbon nanotube array have a diameter of 20 nanometers and a length of 300 micrometers; scrape 100 mg of carbon nanotube arrays, add them to 100 milliliters of ethanol and 100 milliliters In the ionized water mixture, the ultrasonic wave with a power of 400 watts was ultrasonically stirred for 30 minutes to form a floc structure; the floc structure was washed with water; the washed floc structure was placed in a freeze dryer, and quenched to -30°C, freeze for 12 hours; then raise the temperature to -10°C, evacuate to 10Pa, dry for 12 hours, then close the vacuum system, open the air inlet valve of the freeze dryer, take out the sample, and obtain the carbon nanotube sponge Preform; transfer the carbon nanotube sponge preform into a reactor, pass acetylene (flow rate of 10sccm) and argon, and heat to 800 ° C to decompose the acetylene, and carry out carbon nanotube sponge preform in the carbon nano...

Embodiment 2

[0100] Symmetric cells were assembled in a glove box (M. Braun Inert Gas Systems GmbH, Germany) under an argon atmosphere. The working electrode and the counter electrode of the symmetrical cell are lithium metal anodes. 1M LiPF6 with 2 wt% VC in EC:DMC:DEC (1:1:1:1 by volume) was used as electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com