Membrane electrode with gradient structure catalyst layer for fuel cell and preparation method

A fuel cell and gradient structure technology, which is applied to battery electrodes, structural parts, circuits, etc., can solve the problems of high processing cost of the flow field structure, unfavorable mass production and low cost of products, and high requirements for raw materials of the flow field, so as to achieve the goal of lifting the membrane Electrode performance, improving coating efficiency, improving the effect of mass transfer polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

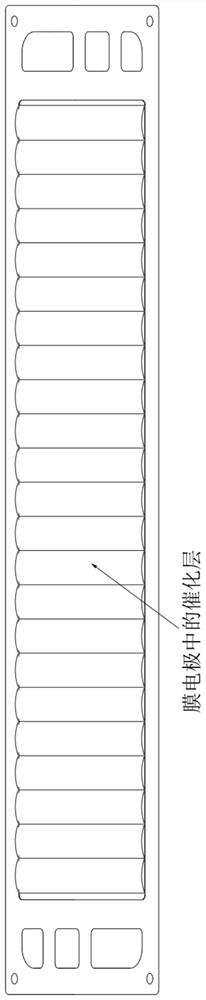

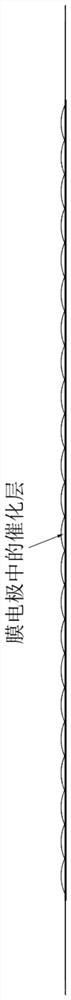

[0034] A membrane electrode structure for a fuel cell with a gradient structured catalytic layer is described.

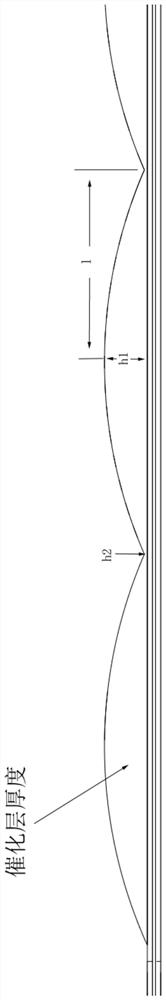

[0035] refer to Figure 1-Figure 3 , a membrane electrode for a fuel cell with a gradient structure catalytic layer, comprising a proton exchange membrane and a cathode and an anode catalytic layer located on both sides of the proton exchange membrane. When assembled into a fuel cell, the length direction of the membrane electrode for the fuel cell is The flow directions of hydrogen and air, and the thicknesses of the cathode and anode catalyst layers are periodically changed along the length direction of the membrane electrode for fuel cells.

[0036] The periodic change is a sine wave change; the crest thickness h1 of the sine wave is 20-30 μm, the trough thickness h2 of the sine wave is 10-18 μm, and the distance 1 between the crest and the trough is 3-19 cm.

[0037] The membrane electrode structure for a fuel cell further includes a gas diffusion layer located...

Embodiment 2

[0039] Weigh 200 mg of platinum-carbon catalyst (platinum loading 50%, brand TKK, model TEC10E40E) in a 50 mL beaker A, add 10 g of deionized water to completely wet the catalyst, and weigh 5% nafion solution (perfluorosulfonic acid) with a mass concentration. Type polymer solution, brand DuPont, model d520) 400mg and n-propanol 70g in beaker B, disperse beaker B uniformly by constant temperature ultrasonic 5min in a constant temperature ultrasonicator, then transfer the solution in beaker B into beaker A, and then use 7g Wash the beaker B with deionized water, transfer the washed deionized water into the beaker A, and adjust the solid content of the solution to 0.05%. Finally, the beaker A was sonicated for 30 minutes at a constant temperature in a constant temperature ultrasonicator, and then sheared with IKA T25 equipment at a high speed of 5000 rpm and a nitrogen atmosphere for 40 minutes, and then vacuum sheared for 5 minutes to obtain a uniformly mixed cathode and anode c...

Embodiment 3

[0043] Weigh 1g of platinum-carbon catalyst (50% platinum load, brand TKK, model TEC10E60TPM) and put it in a 50mL beaker A, add 10g of deionized water to completely wet the catalyst, and weigh 5% nafion solution (brand DuPont, model d520) 20g and n-propanol 6g in beaker B, disperse beaker B evenly by constant temperature ultrasonic 5min in a thermostatic ultrasonicator, then transfer the solution in beaker B into beaker A, then wash beaker B with 30g deionized water, The deionized water was transferred into beaker A, and the solid content of the solution was adjusted to 5%. Finally, the beaker A was sonicated for 30 minutes at a constant temperature in a constant temperature ultrasonicator, and then sheared with IKA T25 equipment at a high speed of 15,000 rpm and a nitrogen atmosphere for 40 minutes, and then vacuum sheared for 5 minutes to obtain a uniformly mixed cathode and anode catalyst layer slurry.

[0044] Then, the uniformly dispersed cathode and anode catalyst layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com