Functional floating yoghourt and preparation method thereof

A functional, yogurt technology, applied in the field of food processing, can solve the problems of high calorie, unfavorable to human health, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

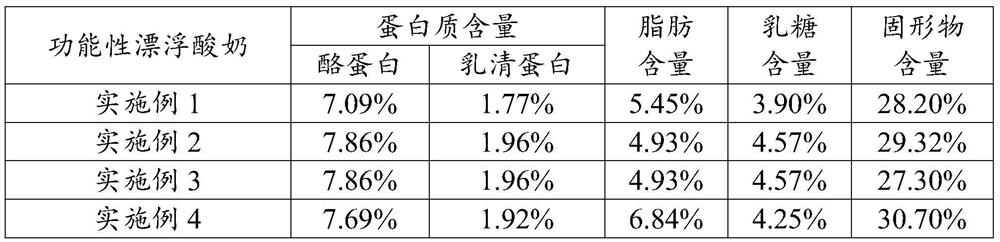

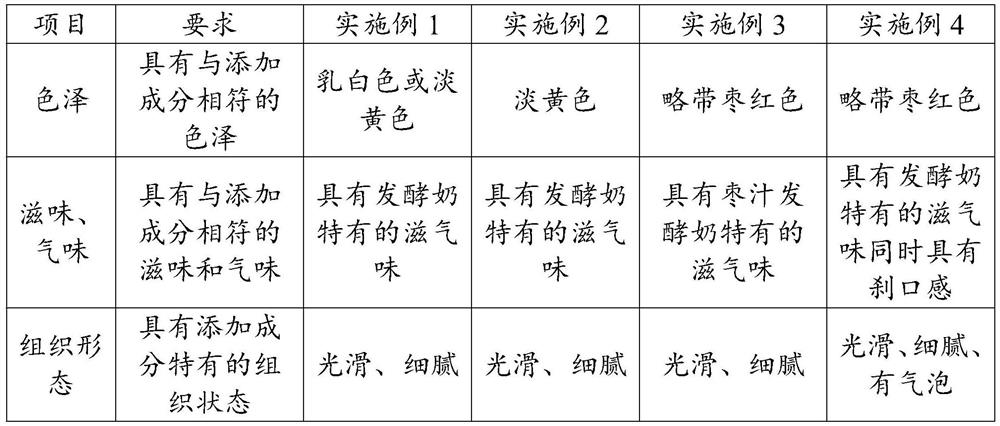

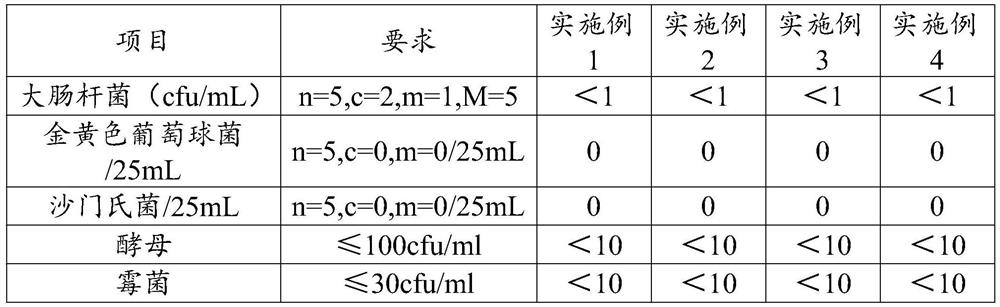

Examples

Embodiment 1

[0036] Functional floating yogurt, including the following raw materials: 420g milk, 150g collagen solution, 100g concentrated milk protein solution, 100g acerola cheese sauce, 50g cream, 25g xylitol, 25g inulin, 50g concentrated milk, compound food additives (gelatin, rice flour, gelatin starch, hydroxypropyl distarch phosphate, gelatin, sodium caseinate, lactic acid fatty acid glycerides, diacetyl tartaric acid mono- and di-glycerides, mono- and di-glycerol fatty acid esters, and microcrystalline cellulose ) 20g, probiotics (Bifidobacterium) 1g and compound starter (Lactobacillus bulgaricus, Streptococcus thermophilus) 0.05g;

[0037] The preparation method of the above-mentioned functional floating yogurt specifically comprises the following steps:

[0038] (1) weigh each raw material by the weight of above-mentioned functional floating yogurt;

[0039] (2) 210g milk is warming up to 80 ℃, obtain warming up milk;

[0040] (3) Mix the remaining raw materials except 210g mi...

Embodiment 2

[0046] Functional floating yogurt, including the following raw materials: 270g milk, 200g collagen solution, 200g concentrated milk protein solution, 100g acerola cheese sauce, 50g cream, 50g xylitol, 50g carrot powder, 50g concentrated milk, compound food additives (cassia gum, rice flour, gelatin starch, hydroxypropyl distarch phosphate, gelatin, sodium caseinate, lactic acid fatty acid glycerides, diacetyl tartaric acid mono-diglycerides, mono-diglycerol fatty acid esters and microcrystalline cellulose ) 20g, probiotics (Bifidobacterium) 10g and compound starter (Lactobacillus bulgaricus, Streptococcus thermophilus) 0.05g;

[0047] The preparation method of the above-mentioned functional floating yogurt specifically comprises the following steps:

[0048] (1) weigh each raw material by the weight of above-mentioned functional floating yogurt;

[0049] (2) 135g milk is warming up to 70 ℃, obtain warming up milk;

[0050] (3) Mix the remaining raw materials except 135g milk, ...

Embodiment 3

[0056] Functional floating yogurt, including the following raw materials: 270g of milk, 200g of collagen solution, 200g of concentrated milk protein solution, 100g of acerola cheese sauce, 50g of heavy cream, 50g of trehalose, 30g of carrot powder, 50g of concentrated milk, compound food additives ( Cassia gum, rice flour, gelatin starch, hydroxypropyl distarch phosphate, gelatin, sodium caseinate, lactic acid fatty acid glycerides, diacetyl tartaric acid mono- and di-glycerides, mono- and di-glycerol fatty acid esters, and microcrystalline cellulose) 30g, postbiotics (supernatant of jujube juice after fermentation) 20g and compound starter (Lactobacillus bulgaricus, Streptococcus thermophilus) 0.05g;

[0057] The preparation method of the above-mentioned functional floating yogurt specifically comprises the following steps:

[0058] (1) weigh each raw material by the weight of above-mentioned functional floating yogurt;

[0059] (2) 135g milk is warming up to 70 ℃, obtain wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com