PBT-PC composite material and preparation method and application thereof

A composite material, PBT resin technology, applied in the field of polymer materials, can solve the problem of uneven heating of PBT, achieve excellent dimensional stability, improve crystalline properties, and solve the effect of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0105] A PBT-graphene oxide composite material A1 comprises, in parts by weight: 99 parts of PBT resin, 0.5 part of graphene oxide, 0.04 part of silane coupling agent, and 0.1 part of antioxidant.

[0106] The preparation method of the described PBT-graphene oxide composite material A1 is as follows: according to the formula amount, the PBT resin, graphene oxide, silane coupling agent and antioxidant after the baking material are mixed at high speed in a mixer, and the rotating speed is 700rpm, The mixing time is 10min to keep it uniform; the mixed material is fed into the twin-screw extruder through the main feed, and the temperature of each zone is as follows: the temperature of the first zone is 215°C, the temperature of the second zone is 225°C, and the temperature of the third zone is 235°C , the temperature in the fourth zone is 235°C, the temperature in the fifth zone is 235°C, the temperature in the sixth zone is 235°C, the temperature in the seventh zone is 235°C, the ...

preparation example 2-5

[0108] A PBT-graphene oxide composite material, denoted as A2-A5 respectively, differs from Example 1 only in that the consumption of the components is different, as shown in Table 1; the types and preparation methods of the components are the same as those of the Example 1 is the same.

Embodiment 1

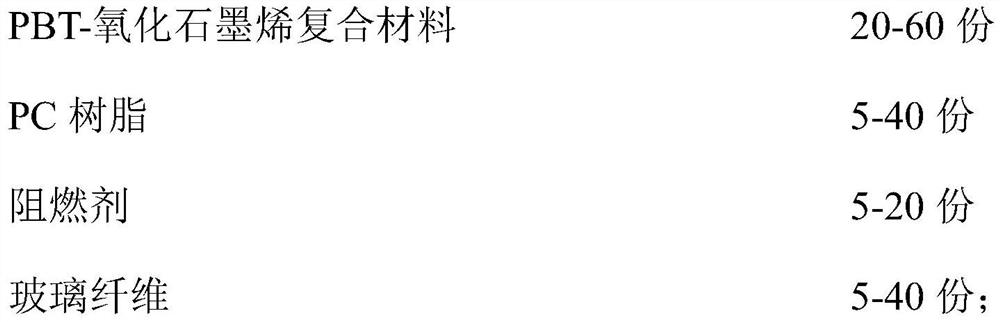

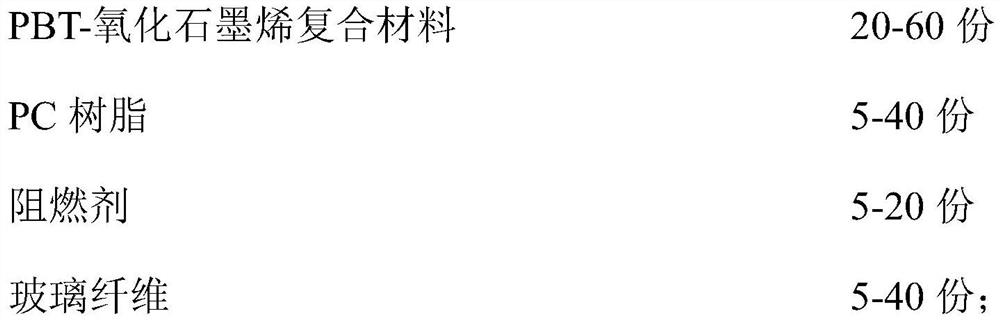

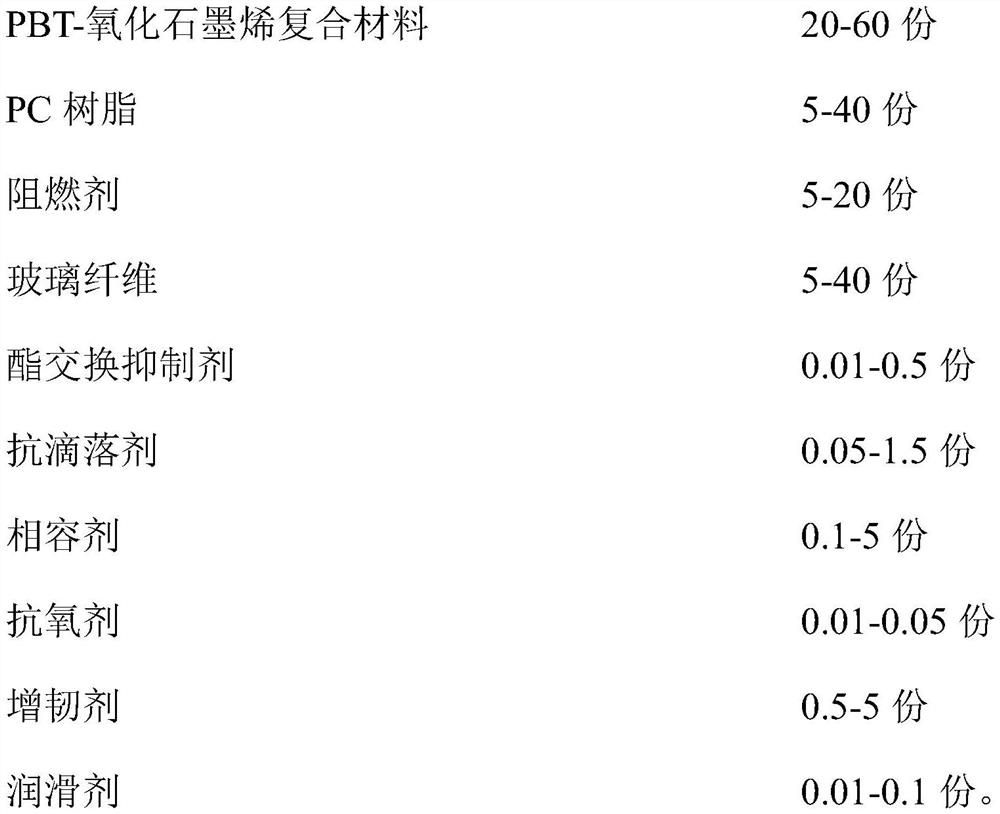

[0120] A PBT-PC composite material, comprising the following components in parts by weight:

[0121]

[0122] The preparation method of the PBT-PC composite material is as follows: according to the formula amount, the baked PBT-graphene oxide composite material, PC resin, flame retardant, glass fiber, transesterification inhibitor, anti-drip agent, compatibility Mixing agent, antioxidant, toughening agent and lubricant in a mixer, the mixing speed is 500rpm, and the mixing time is 15min; the mixed material is added to the twin-screw extruder, and the temperature of each zone is set as follows: 1. The temperature of zone 2 is 220℃, the temperature of zone 2 is 230℃, the temperature of zone 3 is 240℃, the temperature of zone 4 is 240℃, the temperature of zone 5 is 240℃, the temperature of zone 6 is 240℃, the temperature of zone 7 is 240℃, and the temperature of zone 8 is 240℃. The temperature is 235°C, the temperature of the ninth zone is 235°C, the temperature of the tenth z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com