Method for brewing deep fermentation type rice wine by using single strain

A technology of deep fermentation and strains, which is applied in the direction of microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc., to achieve the effects of improving the growth and metabolism of strains, improving the ability of alcoholization, and inhibiting the growth of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

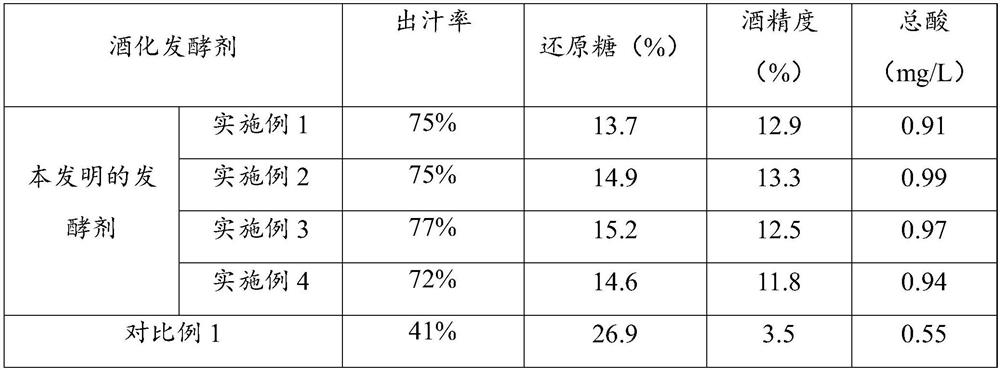

Examples

Embodiment 1

[0031] 1. Preparation of fermentation aids

[0032] (1) Raw material: 15g MgCl 2 , 30g hydroxymethyl cellulose, 20g starch, 70g dextrin, 5g chitosan, 20g acetic acid solution, 30g water and 20g ethanol. Wherein the acetic acid solution is an aqueous acetic acid solution with a mass concentration of 1%

[0033] (2) Preparation method:

[0034] (a) Mix chitosan and acetic acid solution uniformly to prepare chitosan colloid solution.

[0035] (b) Take MgCl2, hydroxymethyl cellulose, starch, and dextrin and mix them uniformly, respectively, add water and ethanol to the mixture for high shear granulation (14 mesh).

[0036] (c) Mixing the chitosan colloidal solution with the granular material in step (b) uniformly, granulating with high shear (14 mesh) again, and drying at 55°C.

[0037] 2. Preparation of clarifier

[0038] (1) 10g of corncob and 12.5g of rice husk were dried, pulverized and passed through a 1mm sieve to obtain mixed powder; the mixed powder was soaked in satu...

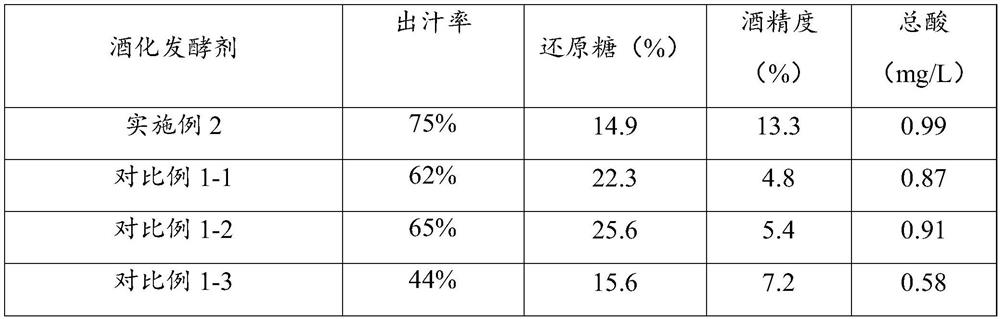

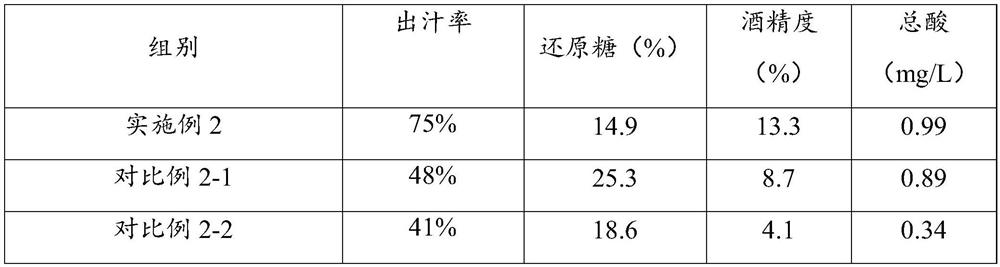

Embodiment 2

[0050] 1. Preparation of fermentation aids

[0051] (1) Raw materials: 22.5g MgCl2, 27g hydroxymethyl cellulose, 24g starch, 65g dextrin, 7.2g chitosan, 21.3g acetic acid solution, 20g water and 30g ethanol. Wherein the acetic acid solution is an aqueous acetic acid solution with a mass concentration of 1%

[0052] (2) The preparation method is the same as that in Example 1.

[0053] 2. Preparation of clarifier

[0054] (1) 20g of corncob and 15g of rice husk are dried, pulverized and passed through a 1mm sieve to obtain a mixed powder; the mixed powder is soaked in saturated CaCO 3 In the solution for 2 hours, take it out and put it in the oven to dry.

[0055] (2) Soak the dried mixed powder in saturated CaCO again 3 In the solution for 2 hours, take it out and put it in an oven to dry;

[0056] (3) Put the dry mixed powder into a muffle furnace, and carry out pyrolysis and carbonization under the protection of N2 to obtain a modified adsorbent material. The temperature...

Embodiment 3

[0066] 1. Preparation of fermentation aids

[0067] (1) Raw material: 25g MgCl 2 , 35g hydroxymethyl cellulose, 26g starch, 50g dextrin, 10g chitosan, 25g acetic acid solution, 15g water and 15g ethanol. Wherein the acetic acid solution is an aqueous acetic acid solution with a mass concentration of 1%

[0068] (2) The preparation method is the same as that in Example 1.

[0069] 2. Preparation of clarifier

[0070] (1) 10g of corncob and 12.5g of rice husk were dried, pulverized and passed through a 1mm sieve to obtain mixed powder; the mixed powder was soaked in saturated CaCO 3 In the solution for 3.5 hours, take it out and put it in the oven to dry.

[0071] (2) Soak the dried mixed powder in saturated CaCO again 3 In the solution for 2.5 hours, take it out and put it in the oven to dry.

[0072] (3) Put the dry mixed powder into a muffle furnace, and perform pyrolysis and carbonization under the protection of N2 to obtain a modified adsorbent material. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com