Electrolyte for high-nickel lithium ion battery, preparation method of electrolyte and high-nickel lithium ion battery

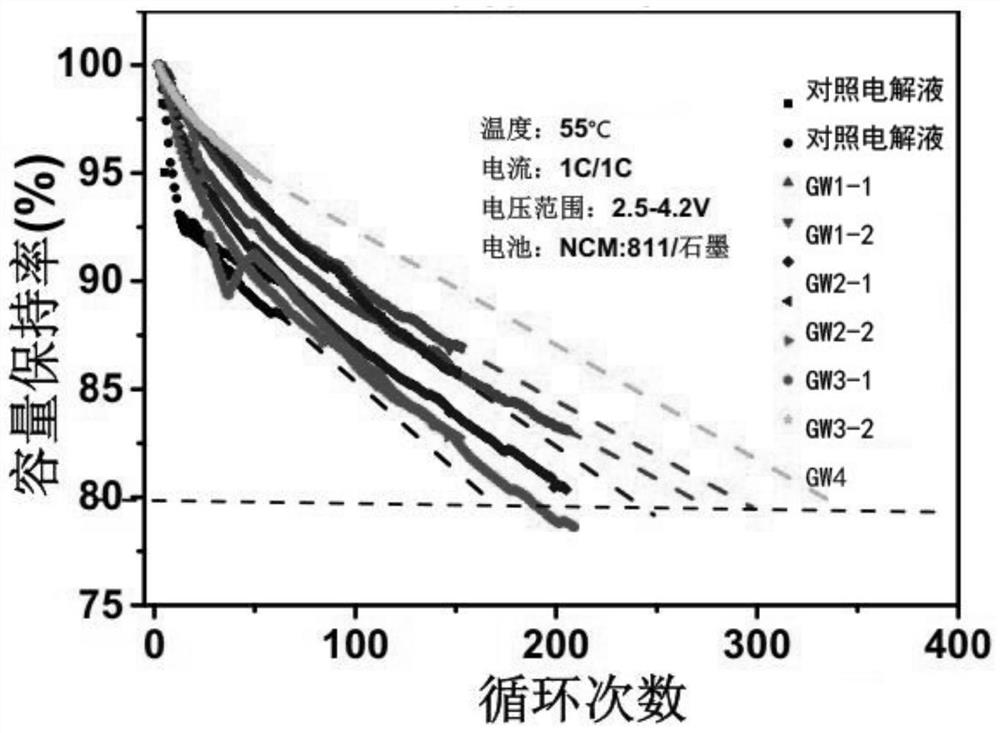

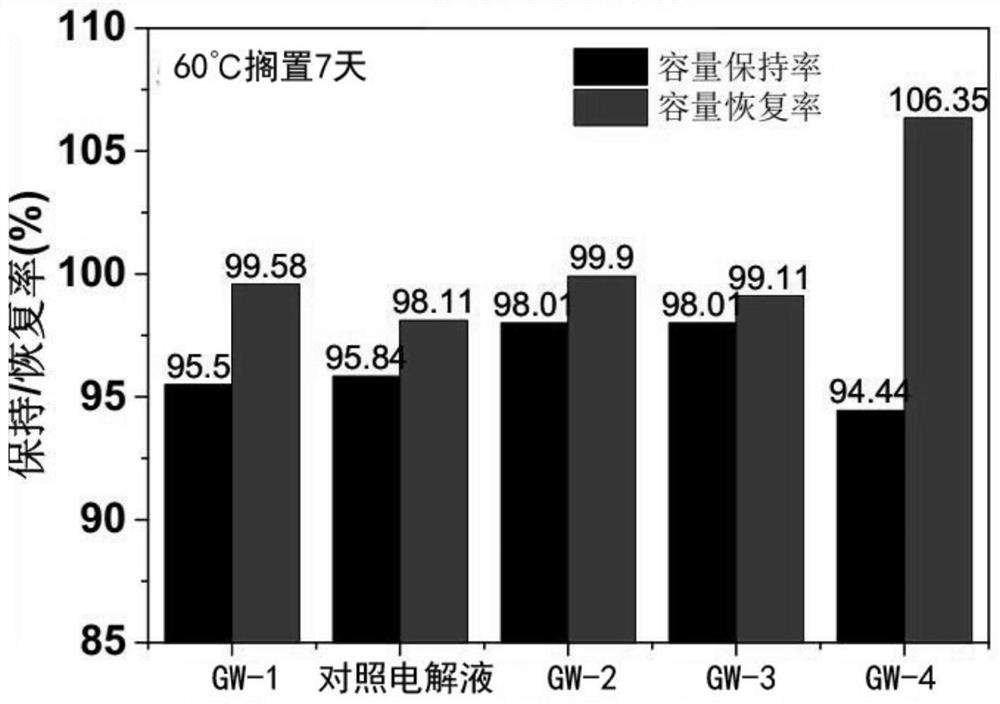

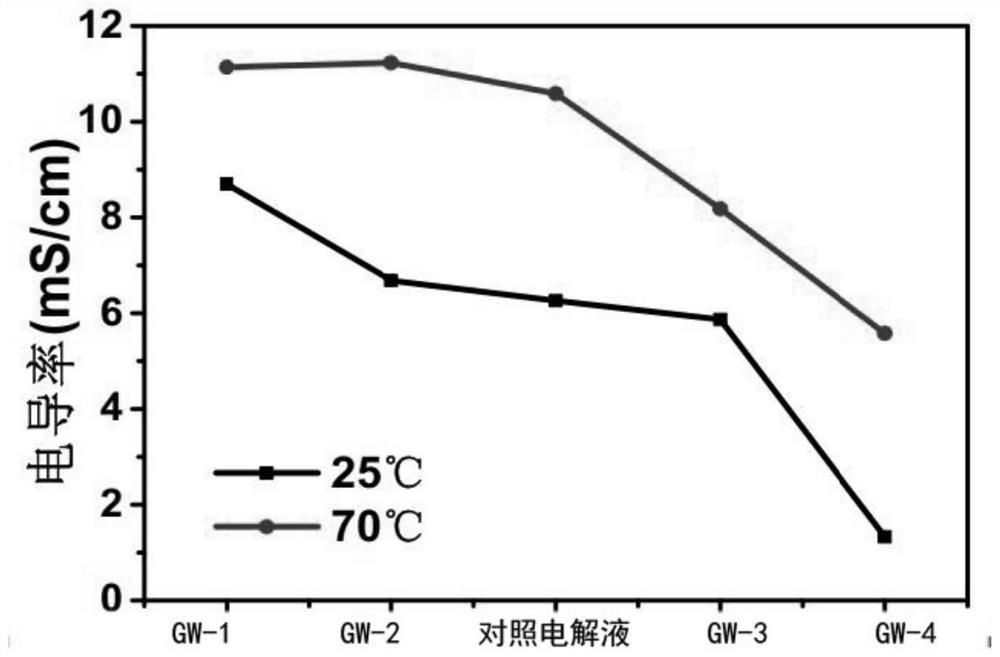

A technology of lithium-ion batteries and ion batteries, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as low high-temperature cycle retention rate, low-voltage cycle performance, unfavorable electrolyte cost, etc., to achieve cycle Improved performance, improved capacity retention, and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] A preparation method of an electrolyte for a high-nickel lithium ion battery, comprising the following steps:

[0059] S1. In an argon-filled glove box (O 2 2 O<3ppm), ethylene carbonate (EC) and methyl ethyl carbonate (EMC) are mixed according to the mass ratio as EC:EMC=1:(1~1.5);

[0060] S2, then slowly add lithium hexafluorophosphate to the non-aqueous organic solvent mixed solution, and configure into a lithium salt solution with a concentration of 1-3.5mol / L;

[0061] S3. Add 0.5wt% to 10wt% based on the total weight of the electrolyte, one or two of unsaturated carbonate [vinylene carbonate (VC) or ethylene ethylene carbonate (VEC) are mixed, and when the two are mixed, the mass The ratio is 1:(1~1.5)], lithium salt [lithium dioxalate borate (LiBOB), lithium difluorooxalate borate (LiDFOB), lithium bistrifluoromethanesulfonimide (LiTFSI), bisfluorosulfonimide Lithium salt (LiFSI) one or more] and 2-methyl maleic anhydride (CA) phosphate compound, fully stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com