Low-smoke halogen-free flame-retardant polypropylene foam material and preparation method thereof

A technology of flame-retardant polypropylene and foam materials, which is applied in the field of polypropylene foam materials, can solve the problems of poor compatibility between flame retardants and polypropylene and unsatisfactory flame-retardant effects, so as to improve flame-retardant effects and reduce hair loss. Smoke density and toxic and harmful gases, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

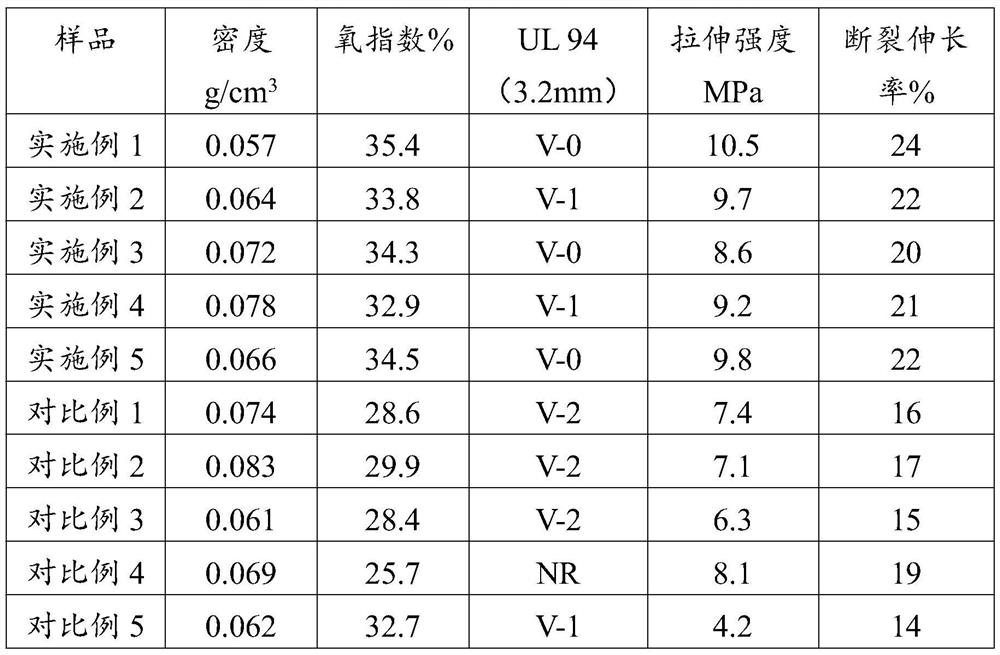

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a low-smoke halogen-free flame-retardant polypropylene foam material, comprising the following steps:

[0047] (1) granulating after mixing linear low density polyethylene, sensitizer, foaming agent, filler, modified glass fiber and antioxidant to obtain foaming master batch;

[0048] Irradiating polypropylene resin and caprolactone-modified methacrylate to obtain modified polypropylene;

[0049] The modified polypropylene, compatibilizer, halogen-free flame retardant and smoke suppressant are mixed and granulated to obtain matrix particles;

[0050] (2) extruding after mixing the foamed master batch, matrix particles and color master batch to obtain a sheet;

[0051] (3) The sheet is irradiated and then foamed to obtain a low-smoke halogen-free flame-retardant polypropylene foamed material.

[0052] In the present invention, the irradiation in step (1) is preferably electron irradiation; the irradiation dose ...

Embodiment 1

[0060] The present embodiment provides a low-smoke halogen-free flame-retardant polypropylene foam material, which is prepared from raw materials containing the following parts by mass:

[0061] Polypropylene resin (melt index is 2.5g / 10min) 50 parts, linear low density polyethylene (melt index is 3g / 10min) 20 parts, PP-g-MAH 5 parts, POE-g-MAH 10 parts, caprolactone 10 parts of modified methacrylate, 9.2 parts of polysiloxane, 13.8 parts of pentaerythritol polyphosphate melamine salt, 7 parts of aluminum hydroxide, 6 parts of azodicarbonamide, 10102 parts of antioxidant, 0.6 part of talcum powder , 3 parts of KH550 modified glass fiber, 1 part of color masterbatch, 2 parts of melamine triallyl ester.

[0062] Its preparation method comprises the following steps:

[0063] (1) mixing linear low density polyethylene, melamine triallyl ester, azodicarbonamide, talc, KH550 modified glass fiber, antioxidant 1010 and granulating at 110°C to obtain foaming master batch;

[0064] El...

Embodiment 2

[0069] The present embodiment provides a low-smoke halogen-free flame-retardant polypropylene foam material, which is prepared from raw materials containing the following parts by mass:

[0070] 42 parts of polypropylene resin (melt index is 2.2g / 10min), 18 parts of linear low density polyethylene (melt index is 3g / 10min), 3 parts of PP-g-MAH, 5 parts of POE-g-MAH, caprolactone 8 parts of modified methacrylate, 6 parts of polysiloxane, 24 parts of pentaerythritol polyphosphate melamine salt, 6 parts of magnesium hydroxide, 6 parts of 4,4'-oxodiphenylsulfonyl hydrazide, antioxidant 10101 parts, 1 part of montmorillonite, 5 parts of KH550 modified glass fiber, 0.5 part of color masterbatch, 1 part of trimethylolpropane trimethacrylate.

[0071] Its preparation method comprises the following steps:

[0072] (1) After mixing linear low density polyethylene, trimethylolpropane trimethacrylate, 4,4'-oxobisbenzenesulfonyl hydrazide, montmorillonite, KH550 modified glass fiber, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com