Low-titanium low-sulfur ferrochrome and production method thereof

A production method and ferrochrome technology, which is applied in the field of ferrochrome alloy, can solve the problems that cannot be produced with high-precision bearing steel, the recovery rate of main element chromium is low, and the energy consumption of the production method is high, so that the product is in good condition, the content of undesired impurities is reduced, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

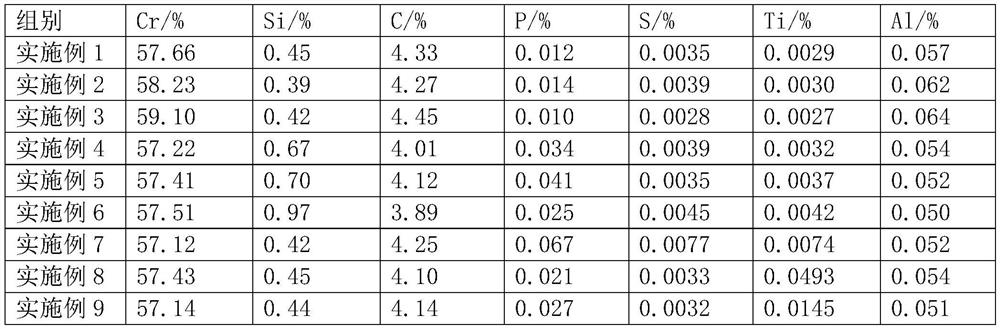

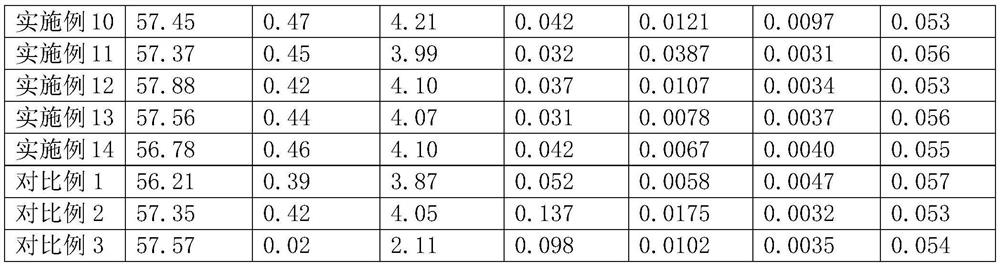

Examples

Embodiment 1

[0038] The present embodiment provides a kind of production method of low titanium and low sulfur ferrochromium, and specifically comprises the following steps:

[0039] S1. Pretreatment of chromite: grind 200kg of chromite into fine powder, add an ethanol solution containing 5wt% of silane coupling agent KH580, the solid-liquid ratio of chromite powder and ethanol solution containing silane coupling agent KH580 1:5g / mL, 1500W ultrasonic heating to 70 ℃, reacting for 1h, further adding 2.4kg silica powder and 4kg lime powder, pelletizing to obtain green pellets; further drying and roasting to obtain pellets with a particle size of 10- 15mm;

[0040] Silica powder SiO 2 The content is not less than 97%, and the particle size is 0.1-1mm; the CaO content of lime powder is not less than 95%, and the particle size is 0.3-1mm;

[0041] S2. Oxygen blowing melting: add the pellets into the furnace, blow oxygen at the top at the same time, raise the temperature until it is completely...

Embodiment 2

[0051] The present embodiment provides a kind of production method of low titanium and low sulfur ferrochromium, and specifically comprises the following steps:

[0052] S1. Pretreatment of chromite: grind 200kg of chromite into fine powder, add an ethanol solution containing 15wt% silane coupling agent KH590, the solid-liquid ratio of chromite powder and the ethanol solution containing silane coupling agent KH590 1:5g / mL, 2500W ultrasonic heating to 90 ℃, reacting for 3h, further adding 2.4kg silica powder and 4kg lime powder, pelletizing to obtain green pellets; further drying and roasting to obtain pellets with a particle size of 10- 15mm;

[0053] Silica powder SiO 2 The content is not less than 97%, and the particle size is 0.1-1mm; the CaO content of lime powder is not less than 95%, and the particle size is 0.3-1mm;

[0054] S2. Oxygen blowing melting: add the pellets into the furnace, and blow oxygen at the top at the same time, heat up to complete melting, and clean...

Embodiment 3

[0064] The present embodiment provides a kind of production method of low titanium and low sulfur ferrochromium, and specifically comprises the following steps:

[0065] S1. Pretreatment of chromite: grind 200kg of chromite into fine powder, add an ethanol solution containing 10wt% silane coupling agent, and the solid-to-liquid ratio of chromite powder and the ethanol solution containing silane coupling agent is 1 : 5g / mL, 1500W ultrasonic heating to 80 ℃, reaction 2h, further adding 2.4kg silica powder and 4kg lime powder, pelletizing to obtain green pellets; Further drying and roasting are carried out to obtain pellets, and the particle size is 10-15mm;

[0066] The silane coupling agent is the compound mixture of KH560 and KH550, and the mass ratio is 5:3;

[0067] Silica powder SiO 2 The content is not less than 97%, and the particle size is 0.1-1mm; the CaO content of lime powder is not less than 95%, and the particle size is 0.3-1mm;

[0068] S2. Oxygen blowing melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com