Lithium hexafluorophosphate tail gas comprehensive utilization method

A technology of lithium hexafluorophosphate and tail gas, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of incomplete condensation of hydrogen fluoride, waste, and low separation efficiency of fluorine and chlorine, so as to achieve efficient utilization of resources and solve fluorine resources. The effect of waste and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

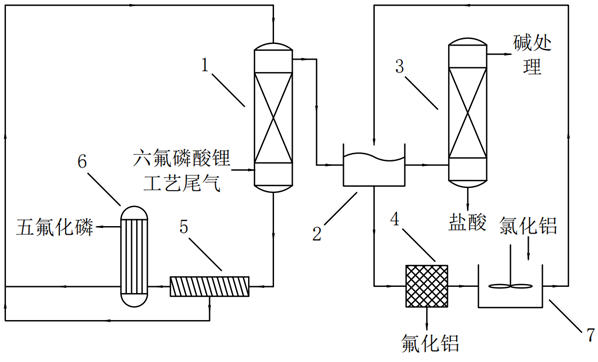

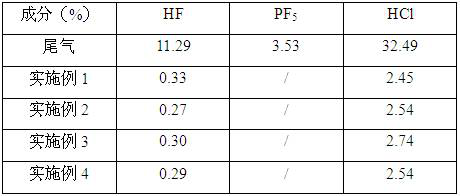

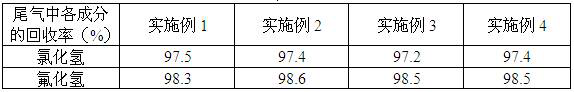

[0031] A method for comprehensive utilization of lithium hexafluorophosphate tail gas, the process is as follows:

[0032] (1) The tail gas of the lithium hexafluorophosphate process is passed into the washing tower 1. The diameter of the washing tower 1 is 0.5m, the height of the tower is 5m, and the wire mesh packing (material is C276 or Monel alloy) is used, and the height of the packing is 3m. The flow rate in the tower 1 is 1m / s, the carbon tetrachloride is used to wash the tail gas with a spray amount of 0.3L / s, and the washing temperature is controlled to 20°C. When the concentration of phosphorus pentafluoride in the washing liquid reaches 40g / L, the washing liquid is passed into the desorption tank 5, desorbed at 65 ° C for 30min, and the desorbed gaseous substances are collected and passed into the condenser 6, and the temperature of the condenser 6 is set to -10 ℃, the collected uncondensed gas is phosphorus pentafluoride, and the condensed carbon tetrachloride and ...

Embodiment 2

[0036] A method for comprehensive utilization of lithium hexafluorophosphate tail gas, the process is as follows:

[0037] (1) Pass the tail gas of the lithium hexafluorophosphate process into the washing tower 1, control the flow rate of the tail gas in the washing tower 1 to be 1.5m / s, and use carbon tetrachloride to wash the tail gas at a spray volume of 0.4L / s at 25°C , when the concentration of phosphorus pentafluoride in carbon tetrachloride reaches 50g / L, the washing liquid is passed into the desorption tank 5, desorbed at 60 ° C for 45min, the gaseous substances collected and desorbed are passed into the condenser 6, and the temperature of the condenser 6 is maintained. 0 ℃, the collected uncondensed gas is phosphorus pentafluoride, and the condensed carbon tetrachloride and the desorbed carbon tetrachloride are mixed and recycled;

[0038] (2) Pass the tail gas after the first washing in step (1) into the reaction tank 2, and use the aluminum chloride solution with a ...

Embodiment 3

[0041] A method for comprehensive utilization of lithium hexafluorophosphate tail gas, the process is as follows:

[0042] (1) Pass the tail gas of the lithium hexafluorophosphate process into the washing tower 1, control the flow rate of the tail gas in the washing tower 1 to be 2m / s, and use carbon tetrachloride to wash the tail gas at a spray volume of 0.5L / s at 30 °C, When the concentration of phosphorus pentafluoride in the carbon tetrachloride reaches 60 g / L, the washing liquid is passed into the desorption tank 5, desorbed at 50 ° C for 60 min, and the desorbed gaseous substances are collected and passed into the condenser 6, and the temperature of the condenser 6 is maintained at 20 ℃, the collected uncondensed gas is phosphorus pentafluoride, and the condensed carbon tetrachloride and the desorbed carbon tetrachloride are mixed and recycled;

[0043] (2) Pass the tail gas after the first washing in step (1) into the reaction tank 2, and use the aluminum chloride solut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap