Preparation method of multifunctional all-fiber-based piezoelectric nano generator

A nanogenerator, full fiber technology, applied in generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, fiber processing, etc., can solve the problem of increasing the overall thickness of piezoelectric nanogenerator, hindering pressure Electric nanogenerators are widely used, and the air permeability of the device is reduced, so as to achieve the effects of excellent antibacterial performance, stable antibacterial performance and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method (method for short) of a multifunctional full-fiber-based piezoelectric nanogenerator, which is characterized in that the method comprises the following steps:

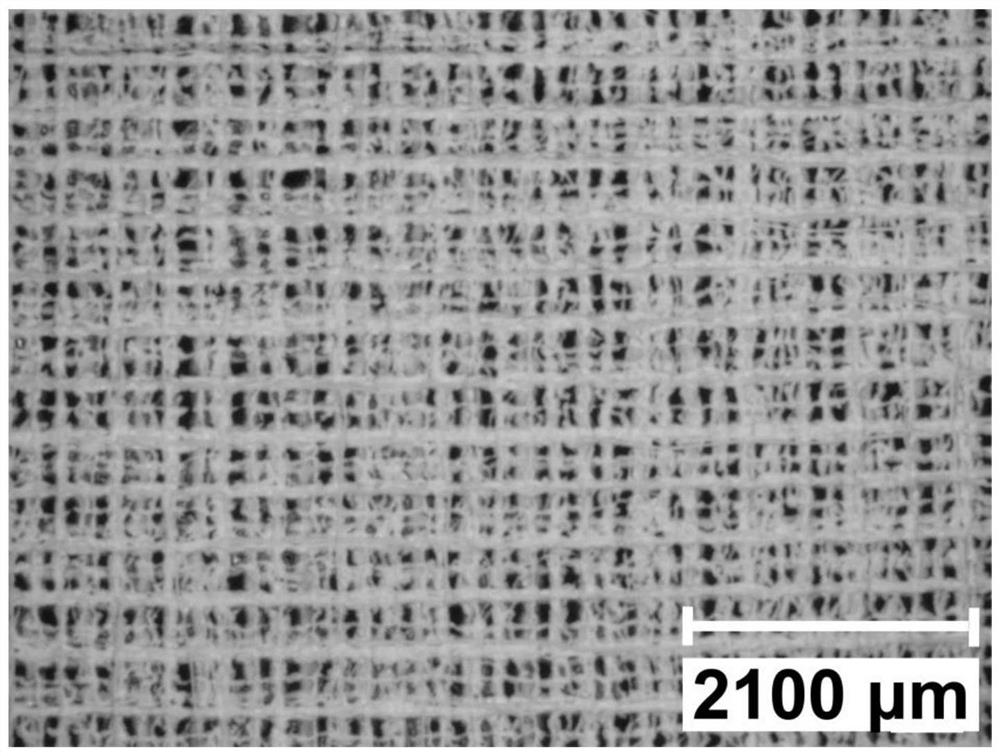

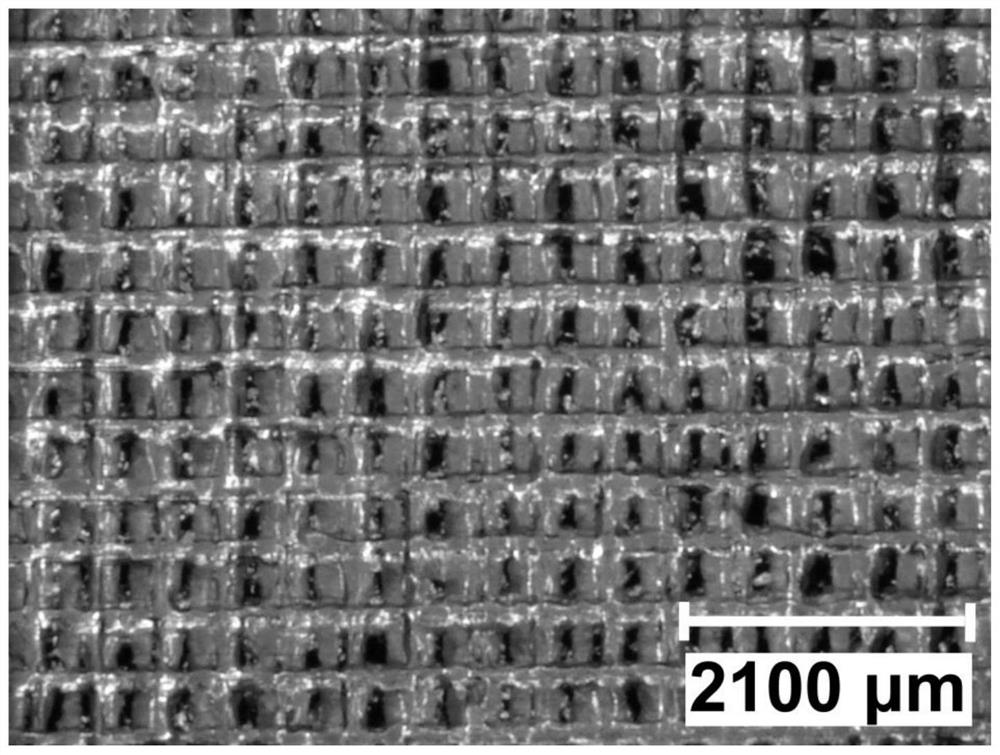

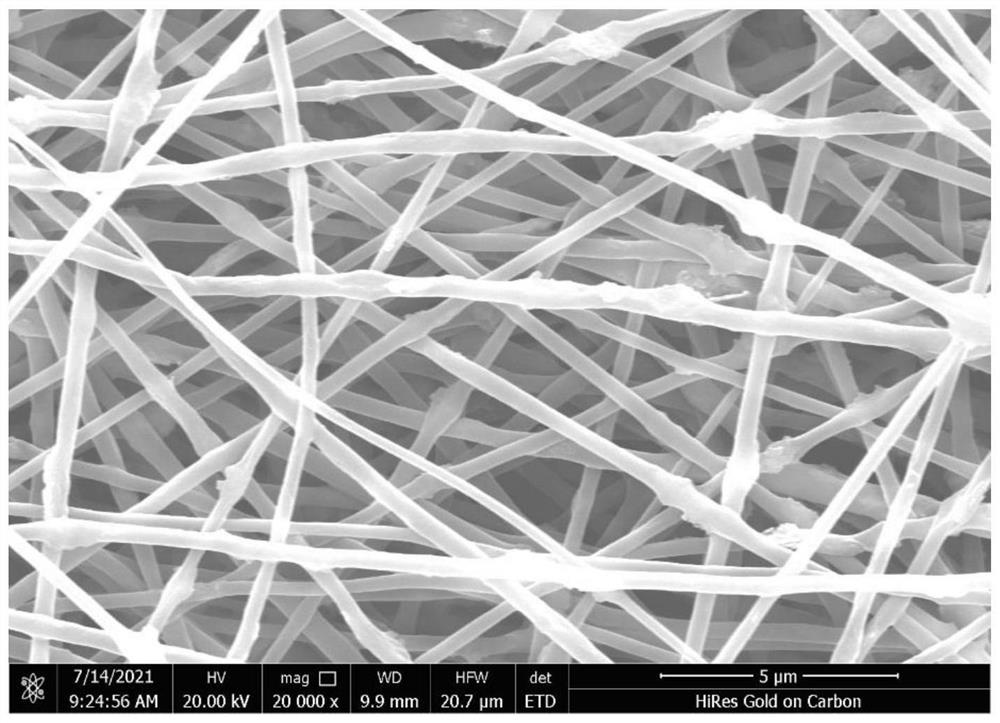

[0029] Step 1. Mix piezoelectric polymer, antibacterial nanoparticles and piezoelectric polymer solvent to form a mixture of piezoelectric polymer / antibacterial nanoparticles; then use the mixture of piezoelectric polymer / antibacterial nanoparticles as spinning liquid, using the electrostatic direct writing method to prepare the electrostatic direct writing nanofiber membrane with the fibers arranged in an orderly manner;

[0030] Preferably, in step 1, the piezoelectric polymer is PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene) or PAN, the antibacterial nanoparticles are ZnO or silver nanowires, and the piezoelectric polymer solvent is N,N- A mixed solvent of dimethylformamide and acetone;

[0031] When the piezoelectric polymer adopts PVDF-HFP, the specific p...

Embodiment 1

[0054] (1) Dissolve 1g of PVDF-HFP powder in a mixed solvent of 4.3g of N,N-dimethylformamide and 1.843g of acetone at room temperature, stir magnetically at 60°C for 6h under sealed conditions, and heat After finishing, let stand to remove air bubbles to obtain PVDF-HFP solution; at room temperature, add 0.57g ZnO nanoparticles, and ultrasonically for 12 hours at room temperature to obtain a PVDF-HFP / ZnO mixed solution, that is, a spinning solution, in which the PVDF-HFP concentration is 14wt %, the mass of ZnO is 57% of that of PVDF-HFP;

[0055] Then, the syringe containing the mixture of PVDF-HFP / ZnO was fixed in the syringe pump of the electrostatic direct writing device, the flow rate of the spinning solution was 0.1ml / h, the spinning voltage was 3.8kV, the spinning distance was 0.5cm, and the environment The relative humidity is 60±5%; the drying temperature is 85°C, the drying time is 5h, and electrostatic direct writing is performed at room temperature to obtain the e...

Embodiment 2

[0070] (1) Dissolve 1g of PVDF-HFP powder in a mixed solvent of 4.3g of N,N-dimethylformamide and 1.843g of acetone at room temperature, stir magnetically at 60°C for 6h under sealed conditions, and heat After finishing, let stand to remove air bubbles to obtain PVDF-HFP solution; at room temperature, add 0.57g ZnO nanoparticles, and ultrasonically for 12 hours at room temperature to obtain a PVDF-HFP / ZnO mixed solution, that is, a spinning solution, in which the PVDF-HFP concentration is 14wt %, the mass of ZnO is 57% of that of PVDF-HFP;

[0071] Then, the syringe containing the mixture of PVDF-HFP / ZnO was fixed in the syringe pump of the electrostatic direct writing device, the flow rate of the spinning solution was 0.1ml / h, the spinning voltage was 3.8kV, the spinning distance was 0.5cm, and the environment The relative humidity is 60±5%; the drying temperature is 85°C, the drying time is 5h, and electrostatic direct writing is performed at room temperature to obtain the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com