Starch-based biodegradable material and its preparation method

A biodegradable and fully degradable technology, which is applied in the field of starch-based biodegradable materials and their preparation, can solve the problems of unsatisfactory physical and chemical hygiene indicators, poor weather resistance, etc., and achieve the effects of excellent mechanical properties, excellent flexibility, and simplified processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

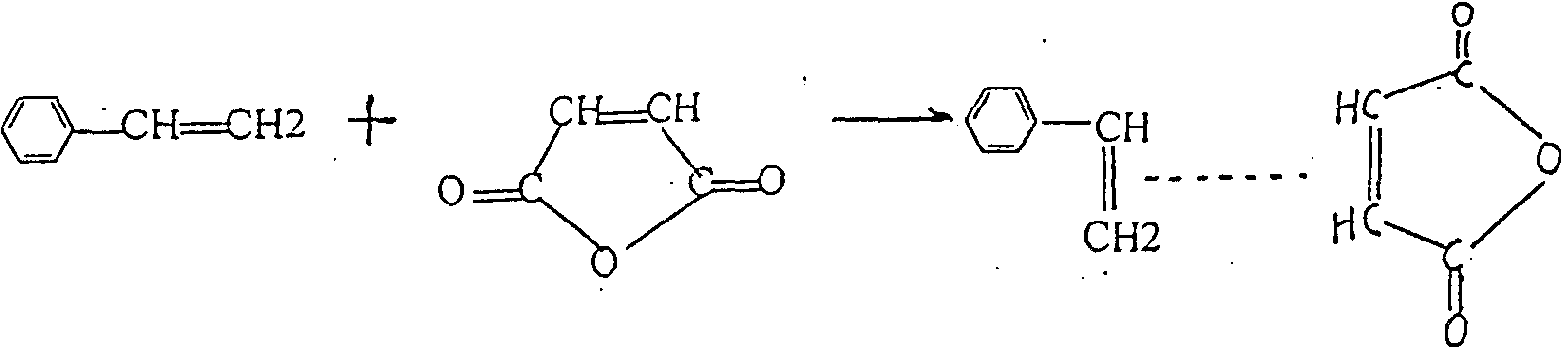

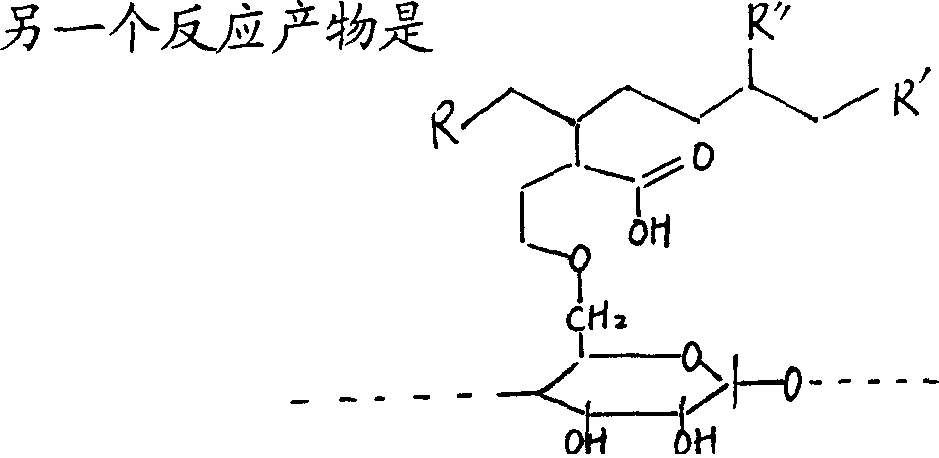

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1. Weigh 38Kg of 100-mesh cornstarch, 2Kg of konjac starch, and 1.84Kg of paraffin, and add them in turn to a special high-speed mixer preheated to 70°C, start stirring, and then add 0.12Kg of oleic acid and 0.12Kg of stearic acid , zinc stearate 0.34g, oleamide 0.53Kg, tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester 0.02Kg, continue to stir, wait for the material temperature in the mixer When the temperature rises to 110°C, add 10Kg of polycaprolactone, discharge into a low-speed cooling mixer, stir at low speed, cool, dehumidify, discharge, and pack;

[0046] Add the above powder into the intermeshing parallel co-rotating twin-screw extruder sheet. The unit temperature is 185-190°C, the die head temperature is 160°C, and the screw speed is 300rpm. Composition 0.74Kg. The extruded sheet is calendered, cooled, shaped, and rolled by a three-roller calender to produce a sheet with a thickness of 0.2-2.5mm, which is white, ...

Embodiment 2

[0047] Example 2: Weigh 40Kg of 100-mesh tapioca starch and 1.82Kg of paraffin, put them into a special heating high-speed mixer preheated to 70°C, start stirring, and add 0.52Kg of adipic acid, 0.42Kg of stearic acid, and 0.85 kg of caprolactam in turn. Kg, 0.13Kg of calcium stearate, 0.05Kg of 2,6-di-tert-butyl-4-methylphenol and continue to stir. When the temperature of the material in the mixer rises to 120°C, add 8Kg of polylactic acid, and the material is cooled and mixed at a low speed. Inside the machine, stirring at low speed, cooling, dehumidification, discharging and packaging.

[0048] Put the upper powder into the intermeshed parallel co-rotating twin-screw extrusion sheet unit, the temperature is 165-175 ° C, the die head temperature is 145 ° C, the screw speed is 300 rpm, and at the same time, inject methyl methacrylate and The composition of acetic anhydride is 0.75Kg, extruded sheet, through three-roller calender, calendered, cooled, shaped, and rolled to obta...

Embodiment 3

[0049] Embodiment three, get 40Kg of early rice starch of 100 orders, swell polyvinyl alcohol 2Kg with hot water, paraffin 1.32Kg, put into the special-purpose high-speed mixer that has been preheated to 70 ℃, start stirring, add stearic acid 0.20Kg successively, hard Zinc fatty acid 0.12Kg, calcium stearate 0.65Kg, oleic acid 0.05Kg, oleamide 0.50Kg, 2,6-di-tert-butyl-4-cresol 0.02Kg Continue to stir until the temperature of the material in the mixer rises to 110°C When the temperature is high, the material is discharged into a low-speed cooling mixer, stirred at a low speed, cooled, dehumidified, discharged, and packaged.

[0050] Put the above powder into the special twin-screw extrusion sheet unit, the temperature is 165-175°C, the die head temperature is 140°C, the screw speed is 300rpm, and at the same time, 1.20Kg of acrylamide is uniformly injected into the second liquid feeding port, and the sheet is extruded. Three-roll calender, calendering, cooling, shaping, windin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com