Preparation of grating device by utilizing ultrashort laser pulse and method for implementing holographic storage

A technology of ultra-short lasers and lasers, which is applied to optical components, instruments, light guides, etc., and can solve problems such as slow writing speed, low production efficiency, and small information storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

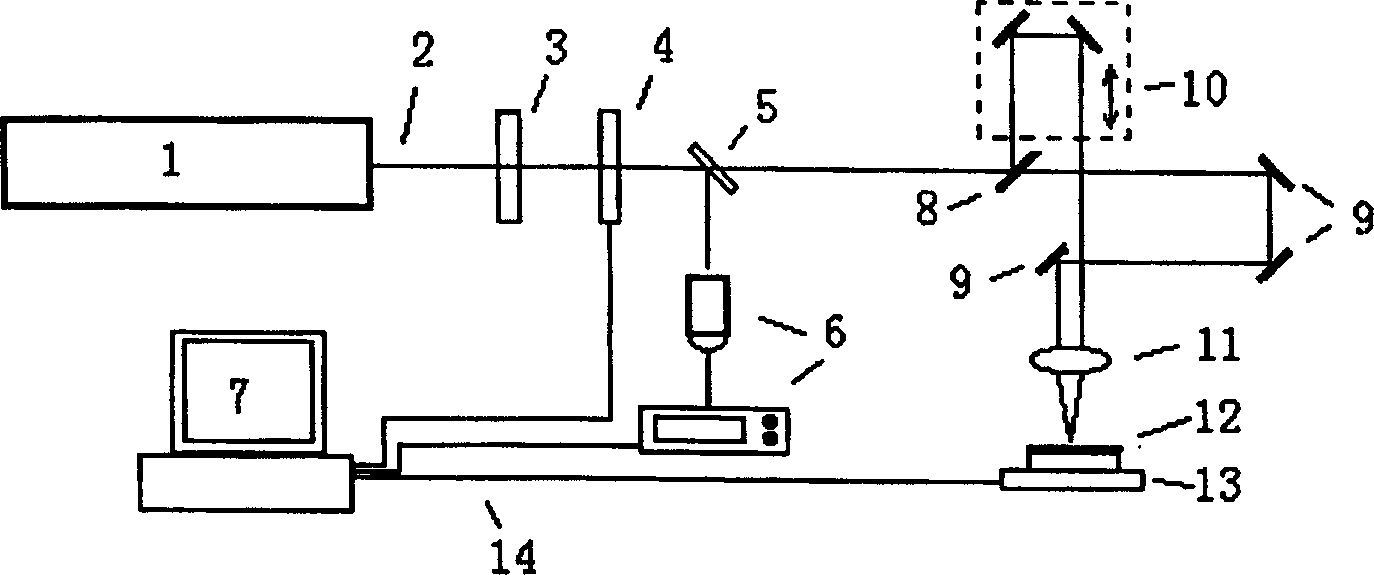

[0079] Such as figure 1 As shown, the ultrashort pulse laser 1 adopts a titanium sapphire femtosecond laser, the wavelength of the output laser beam is 800nm (nanometer), the pulse width is 120fs (femtosecond), and the average power of the laser is 700mW, which is controlled by an energy attenuator 3 Write the magnitude of the laser energy, the shutter 4 selects a single laser pulse, the beam splitter 5 splits a small part of light and uses the energy meter 6 to detect the energy. The single pulse energy of the laser beam 2 is about 400uJ, and the laser beam is divided into two beams of the same energy by the half-mirror 8, one of which passes through an optical delay line 10, and the other beam is reflected by the mirror 9, and at the same time, the focusing The lens 11 is focused on the sample 12 , and the fine-tuning mirror 9 and the focusing lens 11 allow the two beams of light to overlap on the surface of the sample 12 . The sample moving platform 13 controls the posit...

Embodiment 2

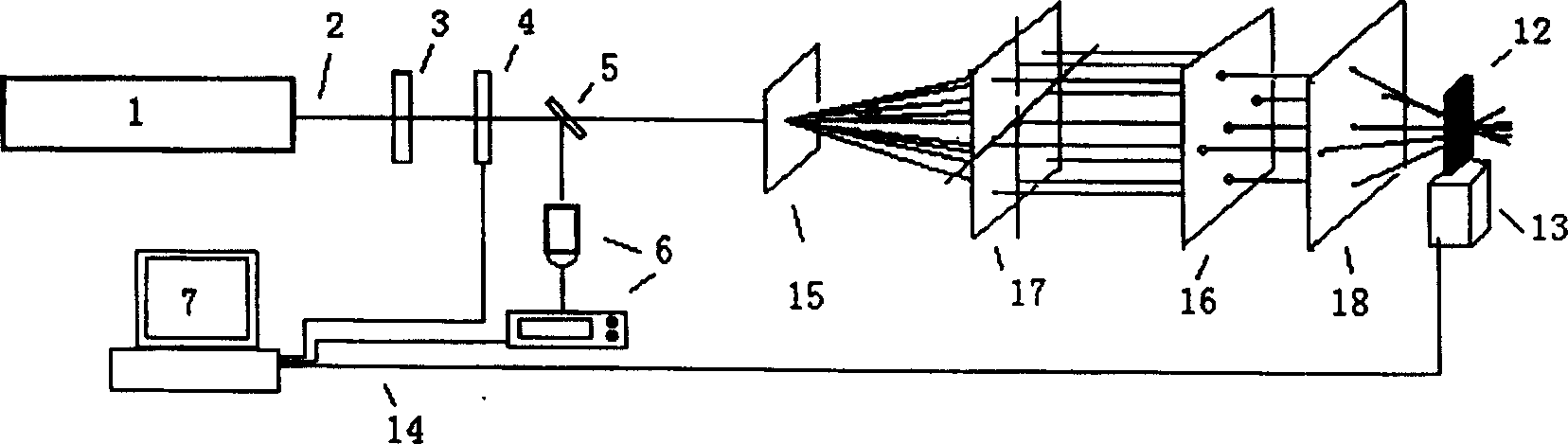

[0089] Such as figure 2 As shown, the ultrashort pulse laser 1 adopts a titanium sapphire femtosecond laser, and the output laser beam 2 has a wavelength of 800nm (nanometer), a pulse width of 120fs (femtosecond), and an average laser power of 700mW, which is controlled by an energy attenuator 3 Write the magnitude of the laser energy, the shutter 4 selects a single laser pulse, the beam splitter 5 splits a small part of light and uses the energy meter 6 to detect the energy. The single pulse energy of the laser beam 2 is about 400 μJ. After the beam splitter 15, the laser light is divided into beams with the same energy and symmetrical distribution, collimated by the collimator lens 17, and then two symmetrical beams are selected by the aperture diaphragm array 16, and focused on the sample 12 by the focusing lens 18 at the same time , the two beams of light coincide at the position on the surface of the sample 12 . The sample moving platform 13 controls the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com