Process for producing L-methionine, aminoacylase strain and aminoacylase

The technology of aminoacylase and production process is applied in the field of L-methionine production process, aminoacylase strains and aminoacylase, and can solve the problems of difficulty in screening high-yielding strains, unsuitability for industrial production, and high preparation cost, Achieve considerable social and economic benefits, save foreign exchange, and efficiently generate aminoacylase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

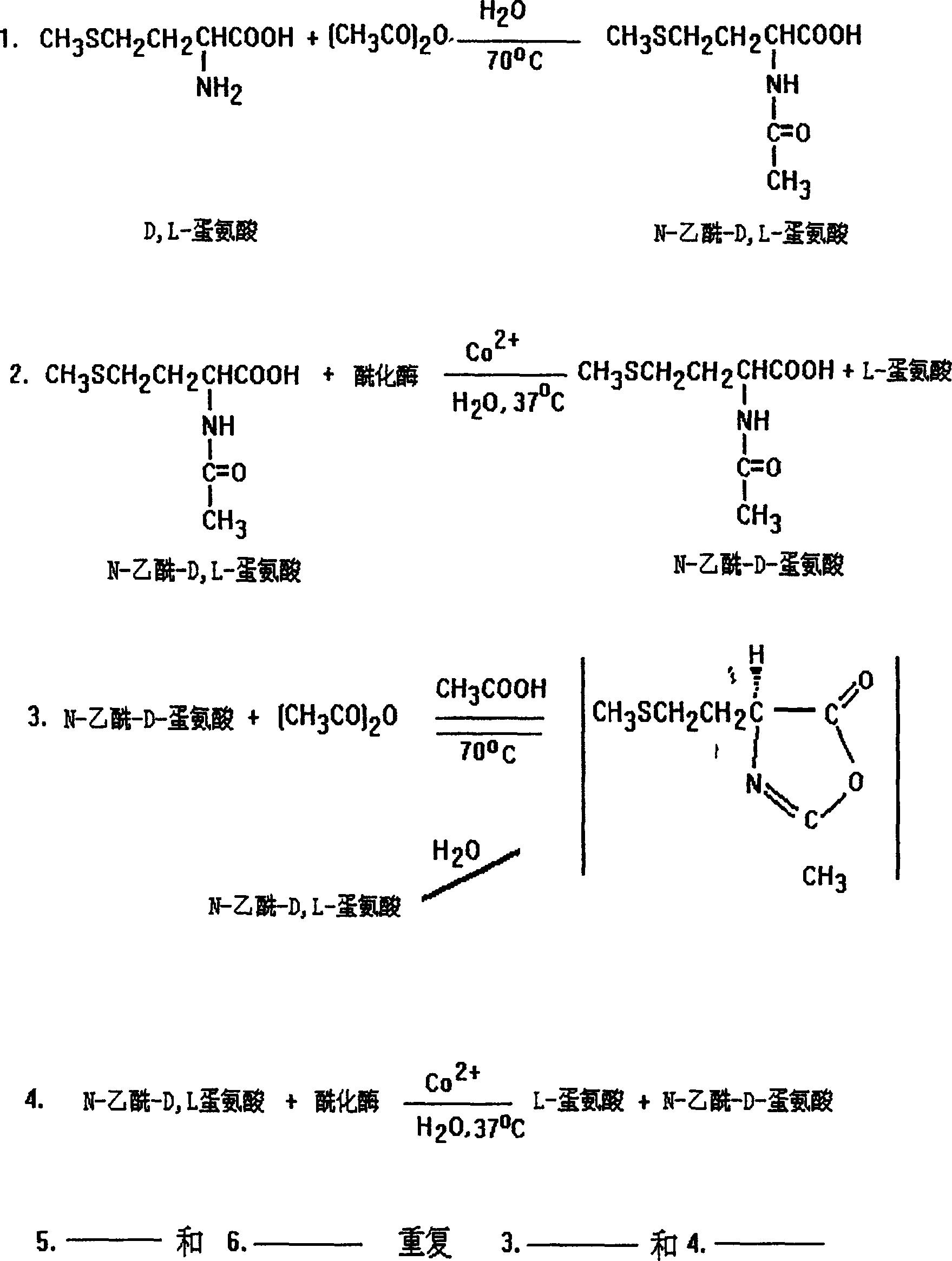

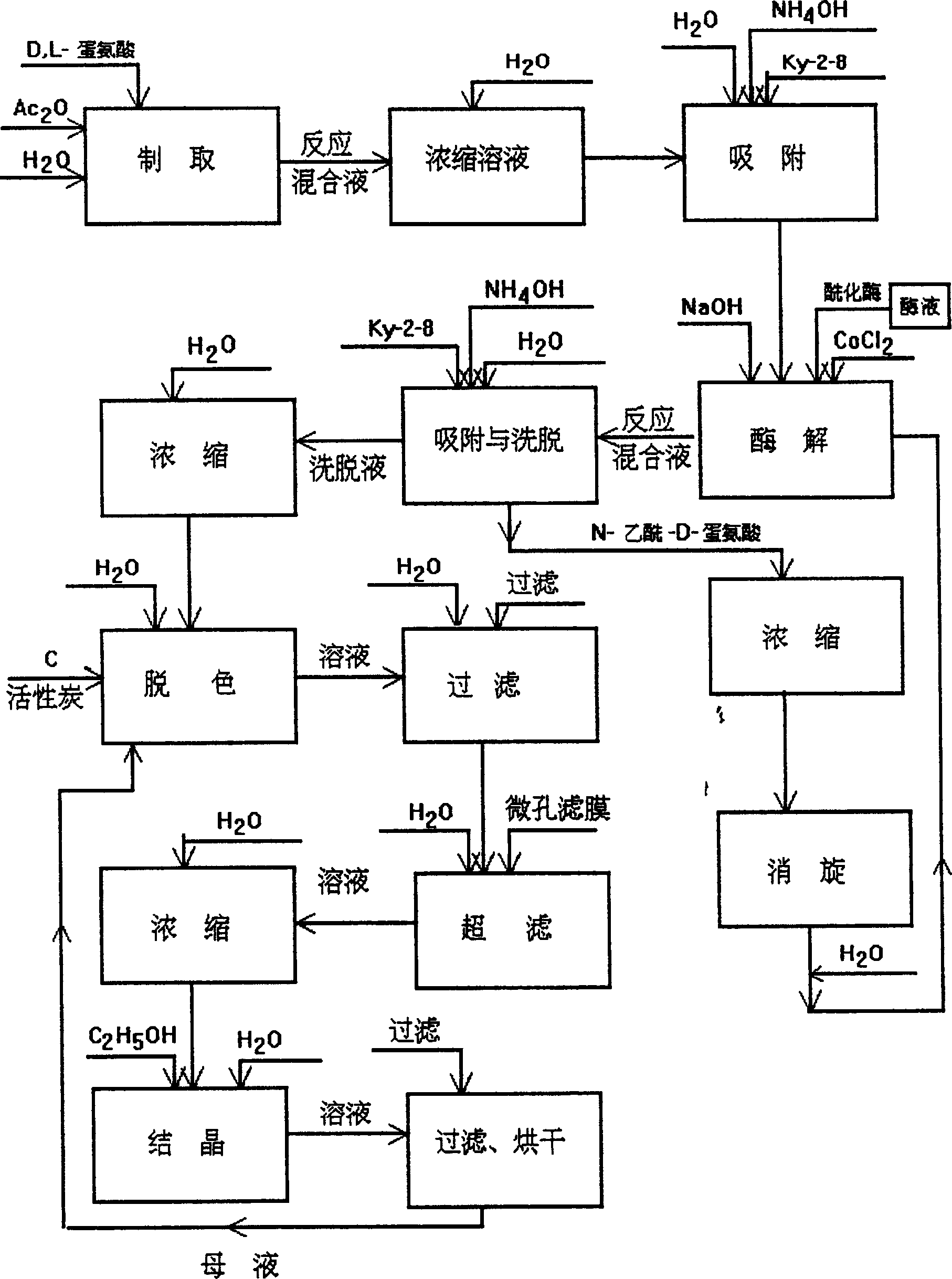

Method used

Image

Examples

Embodiment 1

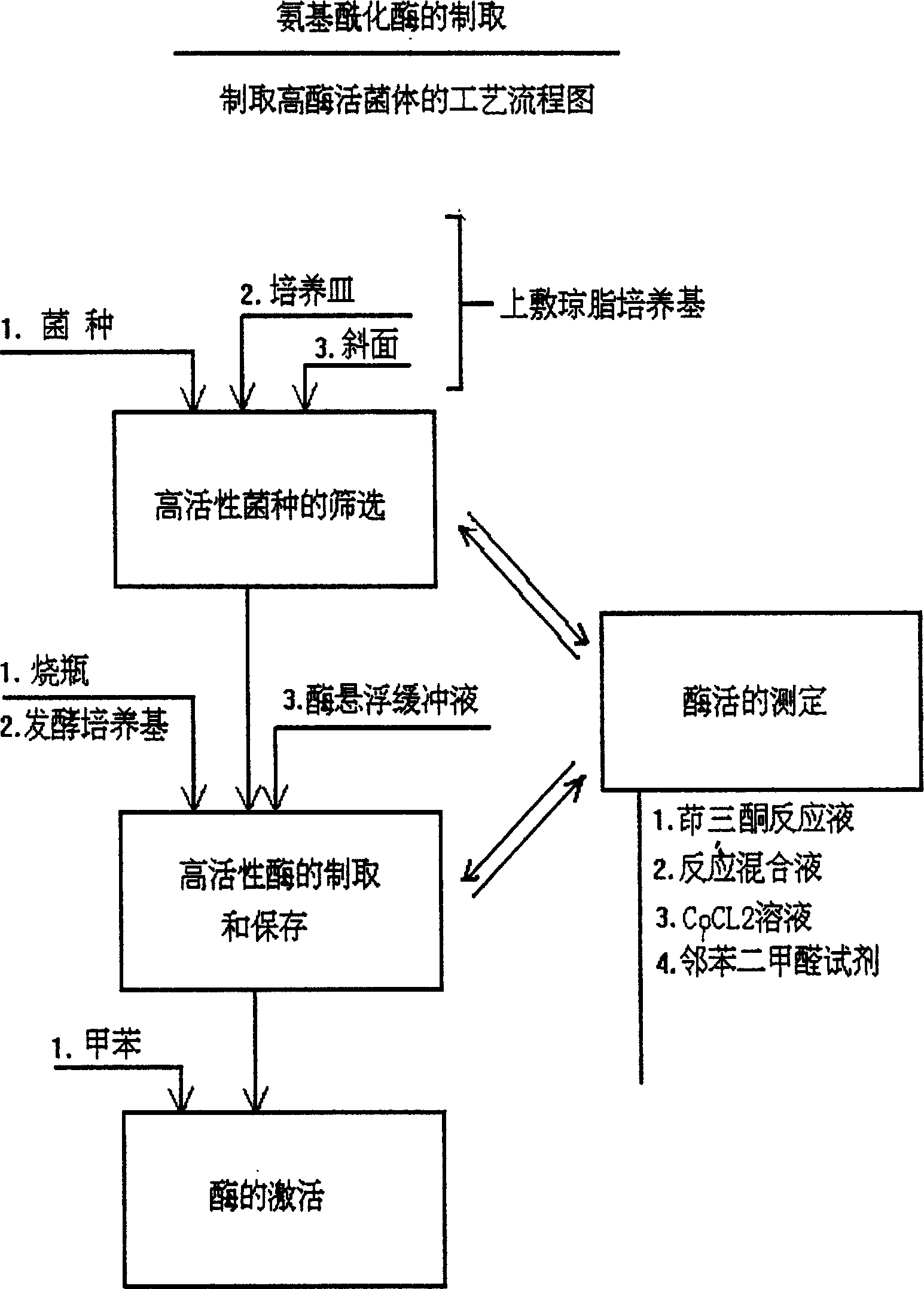

[0043] Embodiment 1, the preparation of aminoacylase

[0044] (1) Preparation of highly active aminoacylase

[0045] 1. The genetic characteristics of the genetically engineered strain XW9707 of the present invention:

[0046] Biotin, sodium succinate double deficient, ampicillin resistance (Apr + ), with pALM118 plasmid carrying Arg - L gene.

[0047] 2. Compatibility of medium.

[0048] No. 1 agar medium

[0049]

[0050]

[0051]

[0052] No. 2 Bacterial Medium

[0053] The ingredients are the same as Medium 1, but no agar is needed. The final concentration of ampicillin was 0.05 g / l.

[0054] 3) Sodium Potassium Phosphate Buffer

[0055] 1 mole KH 2 PO 4 pH=6.8-7.0

[0056] Adjust the pH with 10M NaOH solution.

[0057] 4) Borate buffer

[0058] 0.1 mole H 3 BO 3 pH=9.7.

[0059] 5) Cobalt chloride solution

[0060] 0.02 mol CoCl 2 Soluble in distilled water.

[0061] No. 6 Enzyme Suspension Buffer

Embodiment 2

[0099] The generating reaction of embodiment 2, L-methionine

[0100] The culture of the CGMCC.No.0368 strain obtained in Example 1 is treated with toluene (2%) for more than 30 minutes to obtain activated aminoacylase, and 1000 units of strain treatment or aminoacylase are added to 1 liter of reaction solution. Acylase, 50g N-acetyl-D, L-methionine, adding sodium hydroxide to adjust the pH to 6.5. The reaction liquid was fully stirred, and the enzymatic hydrolysis reaction was carried out under the condition of 37°C. The enzymolysis time is controlled until the content of L-methionine in the enzymolysis solution no longer increases, about 12-16 hours. Water-insoluble matter was removed by centrifugation, and then concentrated under reduced pressure to 1 / 20 (50 ml) of the original volume. An equal volume (50 ml) of cold absolute ethanol was added to the concentrate and the resulting mixture was left overnight at 4°C. The precipitated crystals were collected by filtration an...

Embodiment 3

[0101] The generating reaction of embodiment 3, L-methionine

[0102] The culture solution obtained in Example 1 was centrifuged to obtain bacterial cells. The bacterial cells were suspended in a phosphate buffer (0.1 M potassium phosphate, sodium, pH 6.8). Treat the suspension with ultrasound or 2% toluene to activate the enzyme activity. Then add the activated suspension to 5 times equal volume of 3% sodium alginate sol and stir evenly, then slowly add it dropwise into 0.5M calcium chloride solution to form solidified pellets, and place it in a refrigerator at 4°C overnight , remove the calcium chloride solution, add water to wash 2-3 times, and then put the immobilized enzyme into a glass tube to make an enzyme column. Then N-acetyl-D, L-methionine solution (50 g / l adjusted to pH 6.5 with sodium hydroxide) was passed through the enzyme column at 37° C. to obtain 20 g / l L-methionine solution. Then concentrate under reduced pressure to 1 / 20 of the original volume, then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com