Corrosion inhibitor for steam condensate system of industrial boiler and process for manufacturing same

A technology for steam condensation and industrial boilers, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. problems, to achieve stable operation and prevent acid corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

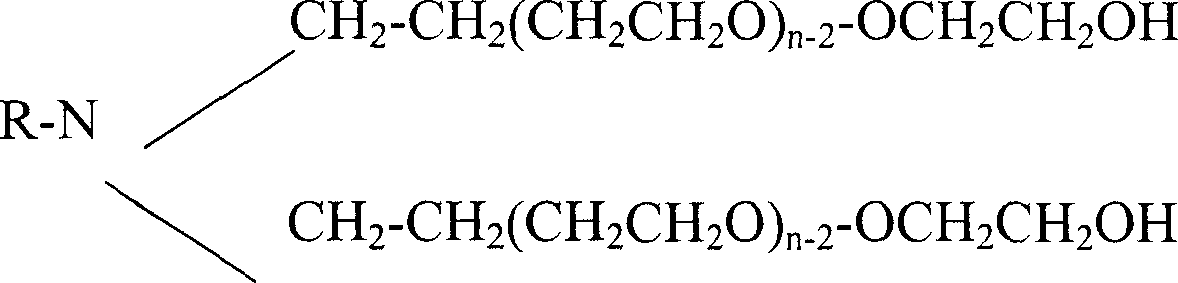

Method used

Image

Examples

Embodiment 1

[0040] In a container with stirring, add 80 ml of deionized water, heat to 55°C, add 0.016 g of Tween 80, 0.004 g of Kespan 60 in turn, stir and mix well, then add 16 g of 18-carbon straight-chain alkylamine and 4 grams of straight-chain alkylamines with 16 carbon atoms, stirred for 5-10 minutes and then cooled to room temperature to obtain an intermediate product. Add 60 grams of cyclohexylamine and 40 grams of ammonia water (referring to the weight of ammonia) in the reaction kettle, start stirring, then add 300 grams of morpholine, stir for 1-5 minutes, add the above-mentioned intermediate product, and stir for another 3 minutes to obtain milky liquid. Corrosion agent, the corrosion inhibition rate of the corrosion inhibitor is 98-99%.

Embodiment 2-13

[0042] The manufacturing steps and conditions of Examples 2-13 are the same as those of Example 1, the difference is that each raw material and the amount of raw materials are shown in Table 1, and the obtained corrosion inhibitor product is an emulsion liquid.

[0043] Example (grams)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com