Process for synthesizing metal oxides and metal oxide having perovskite or perovskite-like crystal structure

A crystal structure, perovskite technology, applied in the direction of oxide/hydroxide preparation, oxygen/ozone/oxide/hydroxide, chemical instruments and methods, etc., can solve the problem of perovskite and perovskite-like metals Oxide does not have problems such as nanocrystalline structure, and achieves the effect of simple method, high specific surface area and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

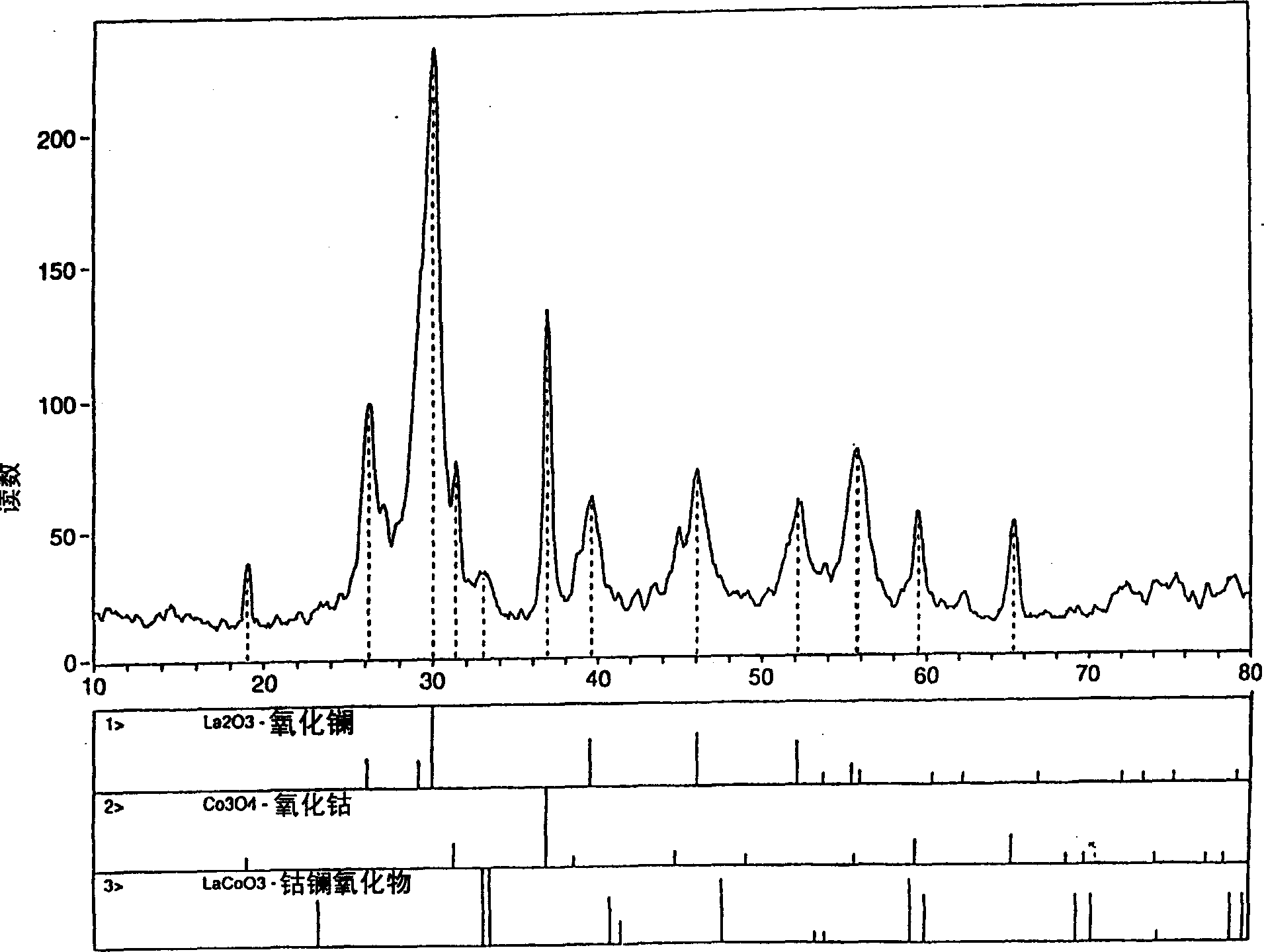

Embodiment 1

[0044] Under standard milling conditions, the starting powders are weighed and mixed in the required proportions to obtain the final component composition. In this particular example, 3.3 grams of lanthanum oxide (La 2 o 3 ) and 1.7 grams of cobalt oxide (Co 3 o 4 ) into a cylindrical tempered steel container with a wall thickness of 5 mm containing 3 tempered steel balls [two balls 7 / 16 inch (11 mm) in diameter and one ball 9 / 16 inch (14mm)]. Preferably, the total weight of powder added to the container is about 5-7 grams. Close the container with a thick lid and seal with a VITON O-ring. In order to vary the grinding impact energy, different sets of grinding balls with various sizes and specific gravity can be used.

[0045] The container is inserted horizontally in the laboratory SPEX TM On the vibration mill, the grinding is generally carried out at a vibration speed of 1000 rpm, and the grinding time is 1-20 hours.

[0046] Although grinding is performed at room t...

Embodiment 2

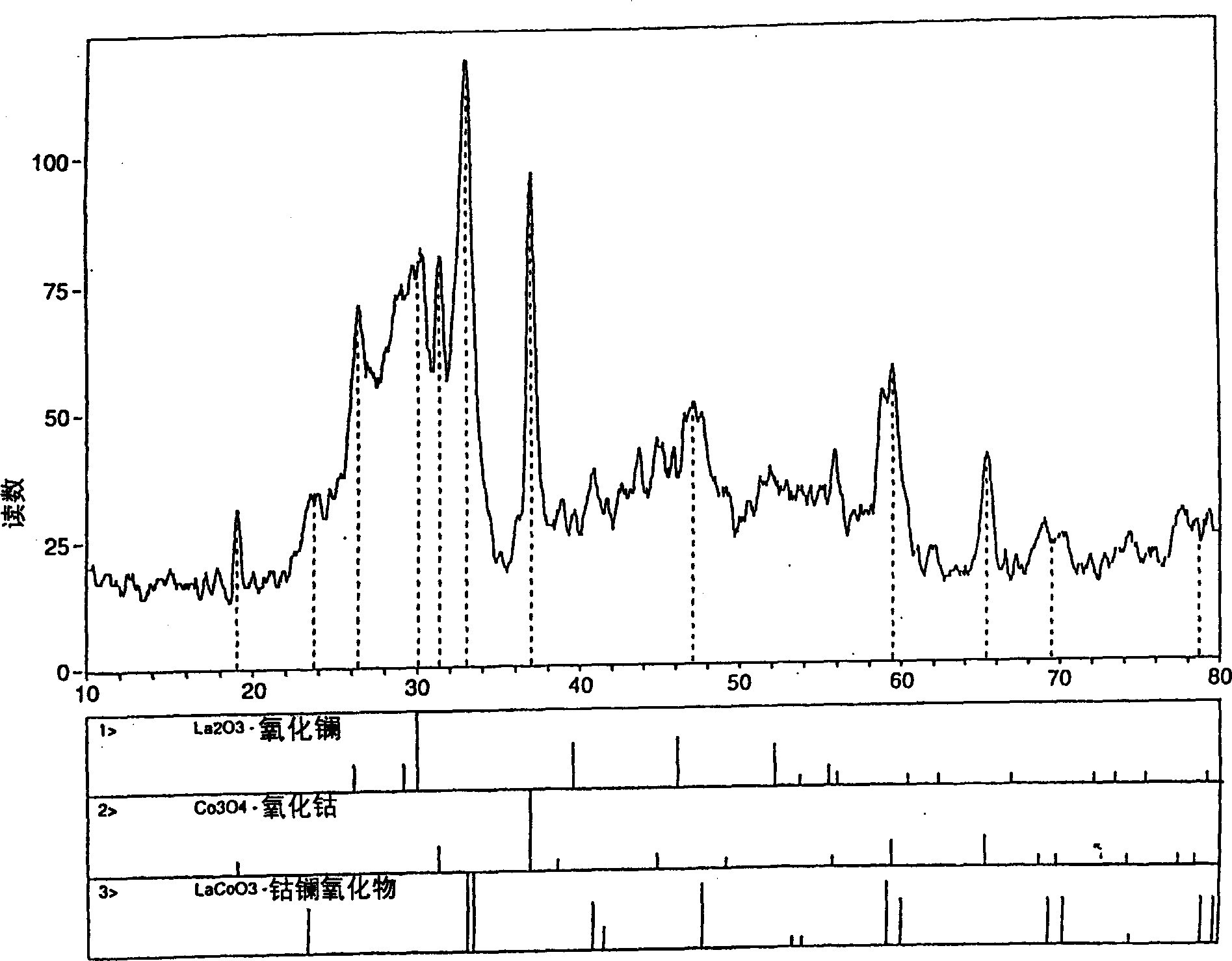

[0057] It is believed that when high energy milling is performed in a sealed vessel, the oxygen contained in the trapped air is rapidly consumed by the exposed metal atoms on the new surfaces created by the broken crystals from repeated impacts in the vessel. Therefore, milling is quickly carried out under an inert nitrogen atmosphere. In this case, the exposed surfaces "stick back" together, reducing the specific surface area of the perovskite. Therefore, just like the first step, in order to increase the specific surface area, the standard grinding atmosphere should be modified.

[0058] For example, in a third preferred embodiment, first, perovskite is synthesized in a sealed container according to Example 1. The newly synthesized perovskite was then further high-energy milled in an atmosphere with constant oxygen content for up to 72 hours. To allow standard air to infiltrate the container, a ring of filter paper is used instead of the container's sealing joint to keep...

Embodiment 3

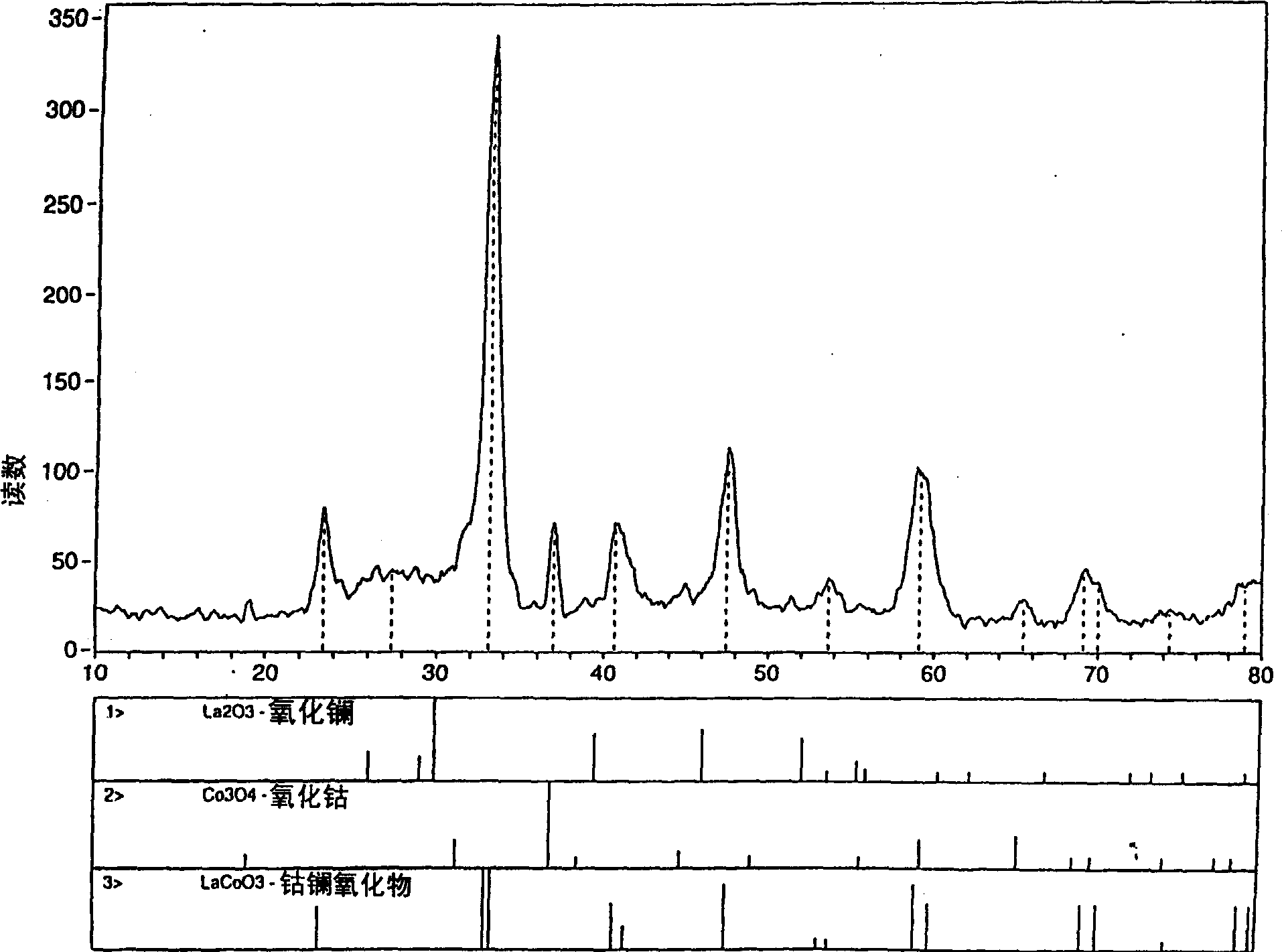

[0061] In the fourth approach, perovskites were prepared in tungsten carbide vessels under standard milling conditions. However, because the density of tungsten carbide balls is higher than that of tempered steel balls, the vibration speed must be reduced to avoid damage to the container or the grinding balls.

[0062] In the fifth scheme, the perovskites obtained under standard grinding conditions were post-treated. Post-processing involves further high-energy milling of the perovskite under a humid atmosphere. Preferably, in order to obtain the humid atmosphere, a simple method is to add a small amount of water (6 drops) to the perovskite (about 5 grams), seal the container, and then carry out standard grinding 1-6 Hour.

[0063] Table 1 shows the LaCoO for obtaining the first, fourth or fifth preferred embodiment of the present invention 3 type perovskite structure, in ground lanthanum oxide (La 2 o 3 ) and cobalt oxide (Co 3 o 4 ) after using the BET method to measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com