Micrometer level porous zirconium dioxide spherical granules

A zirconia, micron-scale technology, applied in zirconia and other directions, can solve problems such as unsatisfactory repeatability, and achieve the effect of narrow particle size distribution and adjustable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

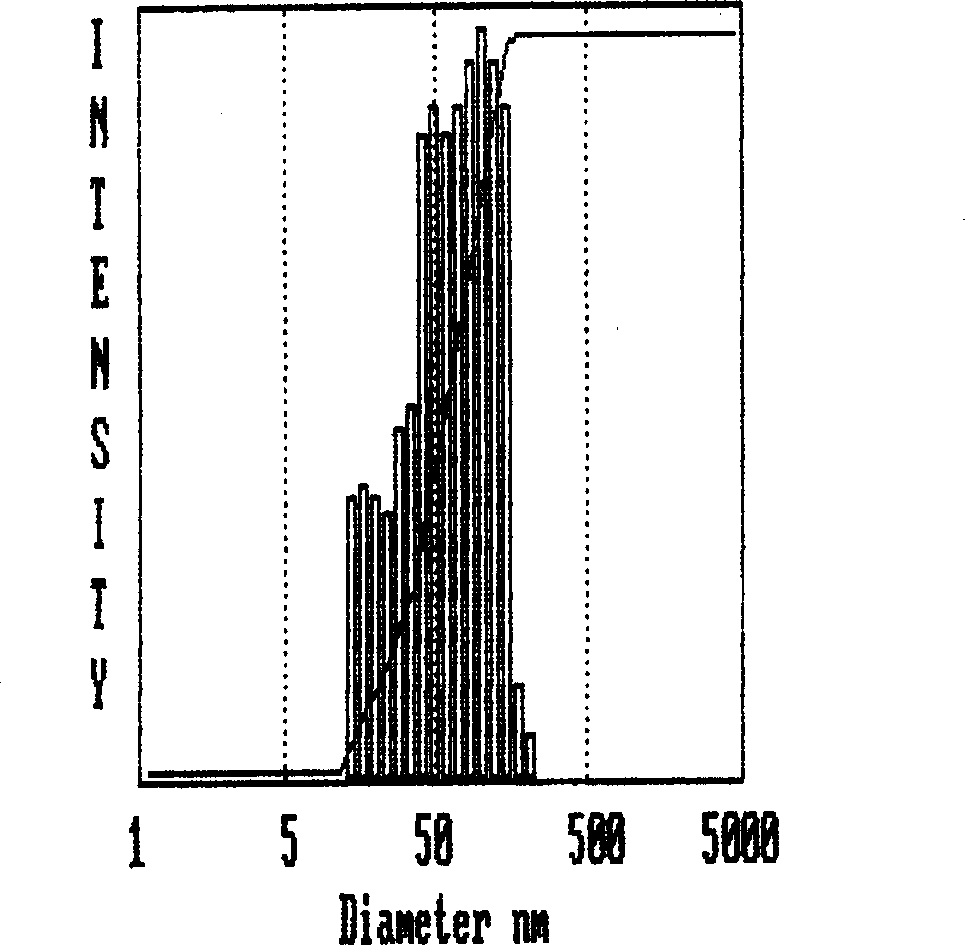

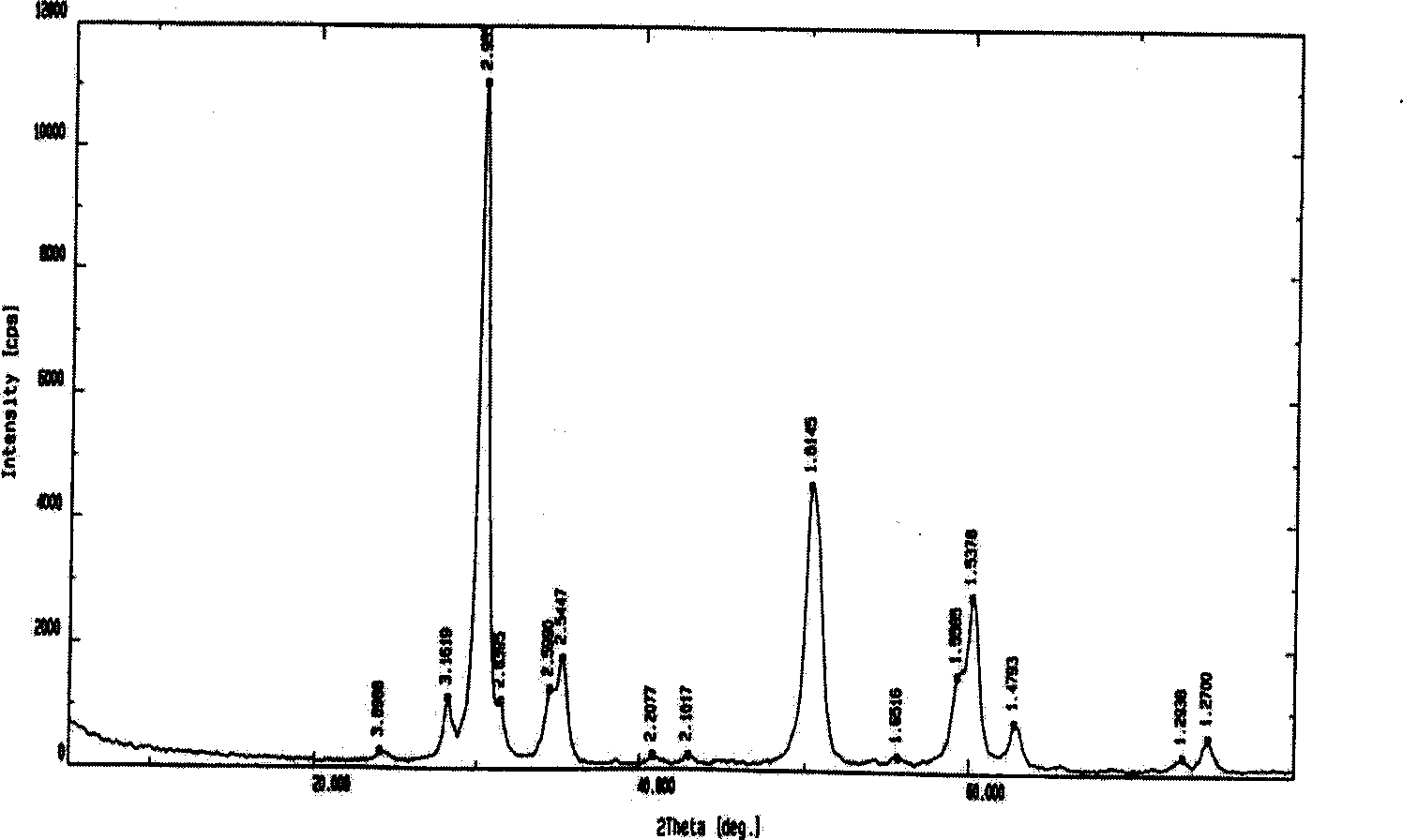

[0022] Add 100g of zirconium oxychloride to a 500mL three-necked round-bottomed flask, add 280mL of deionized water and 3mL of acetylacetone, stir well, add dropwise 25% ammonia water and heat the reactant from room temperature to 85°C, maintaining the pH of the solution at 1- 2. Continue stirring for 10h to obtain ZrO 2 Hydrosol. The hydrosol concentration is 20% (w / w), and its average colloidal particle diameter measured by photon correlation spectrometer is 79.8nm (see Figure 1)

Embodiment 2

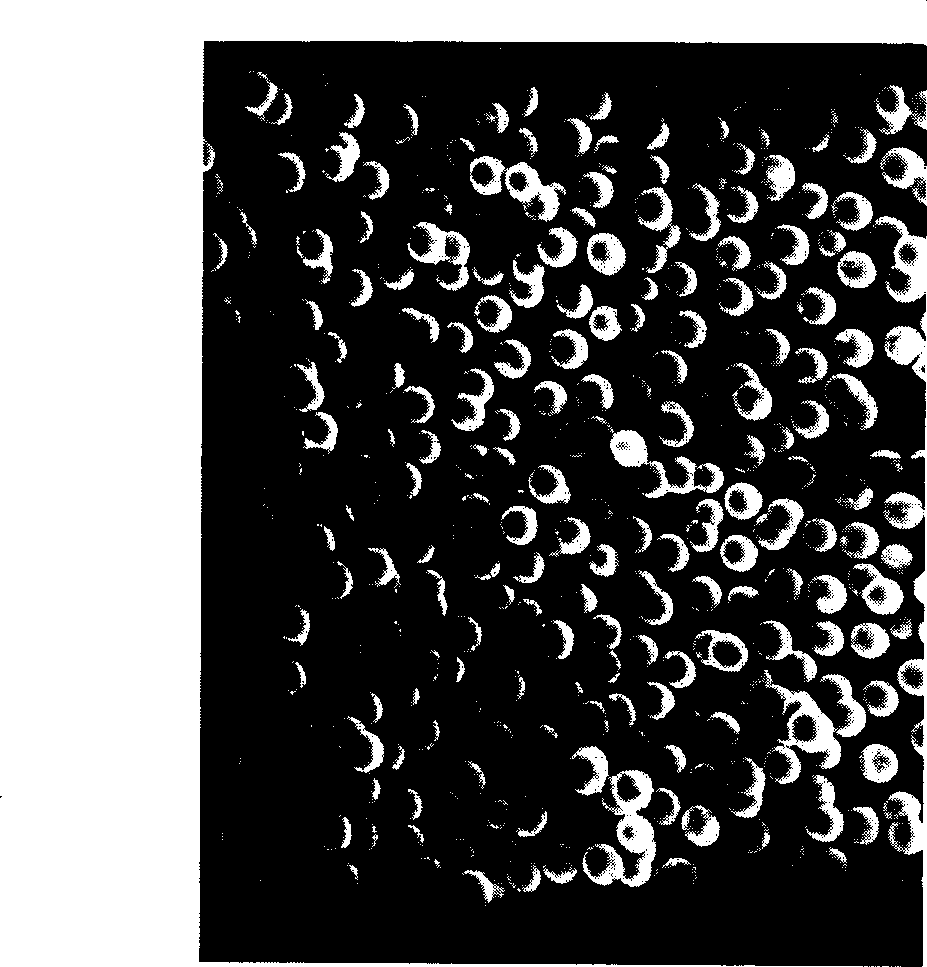

[0024] Get the ZrO that embodiment 1 prepares 2 Add 200mL of hydrosol to a 500mL three-necked round-bottom flask, adjust pH=1.2, add 20g of urea, stir to dissolve completely, add 25mL of 38% formaldehyde solution at 15°C, stir rapidly for 2min, stop stirring, and react at 15°C for 12h, Add 1% NaOH solution to pH = 8, terminate the reaction, ZrO 2 -The resin composite ball sinks to the bottom of the reactor, the appearance is white, and the particle size is 12-15μm. Filter, wash the product with water, then transfer it to a four-neck flask, add isoamyl acetate to remove water azeotropically, and the white composite ball turns light yellow at this time. Then put the product in a vacuum drying oven, maintain a vacuum degree of 0.06MPa, dry at 120°C for 12 hours, and dry at 200°C for 24 hours. In a high-temperature furnace with a thickness of ≤5mm, the temperature rises from room temperature to 200°C at 4°C / min, then from 200°C to 300°C at 1°C / min, from 300°C to 700°C at 2°C / min...

Embodiment 3

[0026] Soak the micron-sized porous zirconia spheres prepared in Example 2 in 6mol / L hydrochloric acid for 24h, then wash with distilled water until neutral; then soak in 1mol / L sodium hydroxide solution for 24h and wash with distilled water until neutral properties; finally put it in a high-pressure axe and add an appropriate amount of water, heat treatment at 200 ° C for 8 hours. The zirconium colloidal microspheres treated above can be directly used in normal phase chromatography, especially suitable for the separation of basic compounds, and can be suitable for mobile phases in the range of pH=1-13. Figure 4 is an example of normal phase chromatographic separation of zirconium gel stationary phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com