Characterization system for property measurement of intermediate infrared waveband semiconductor laser

An infrared band and measurement system technology is applied in the field of performance measurement and characterization of semiconductor lasers in the mid-infrared band. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

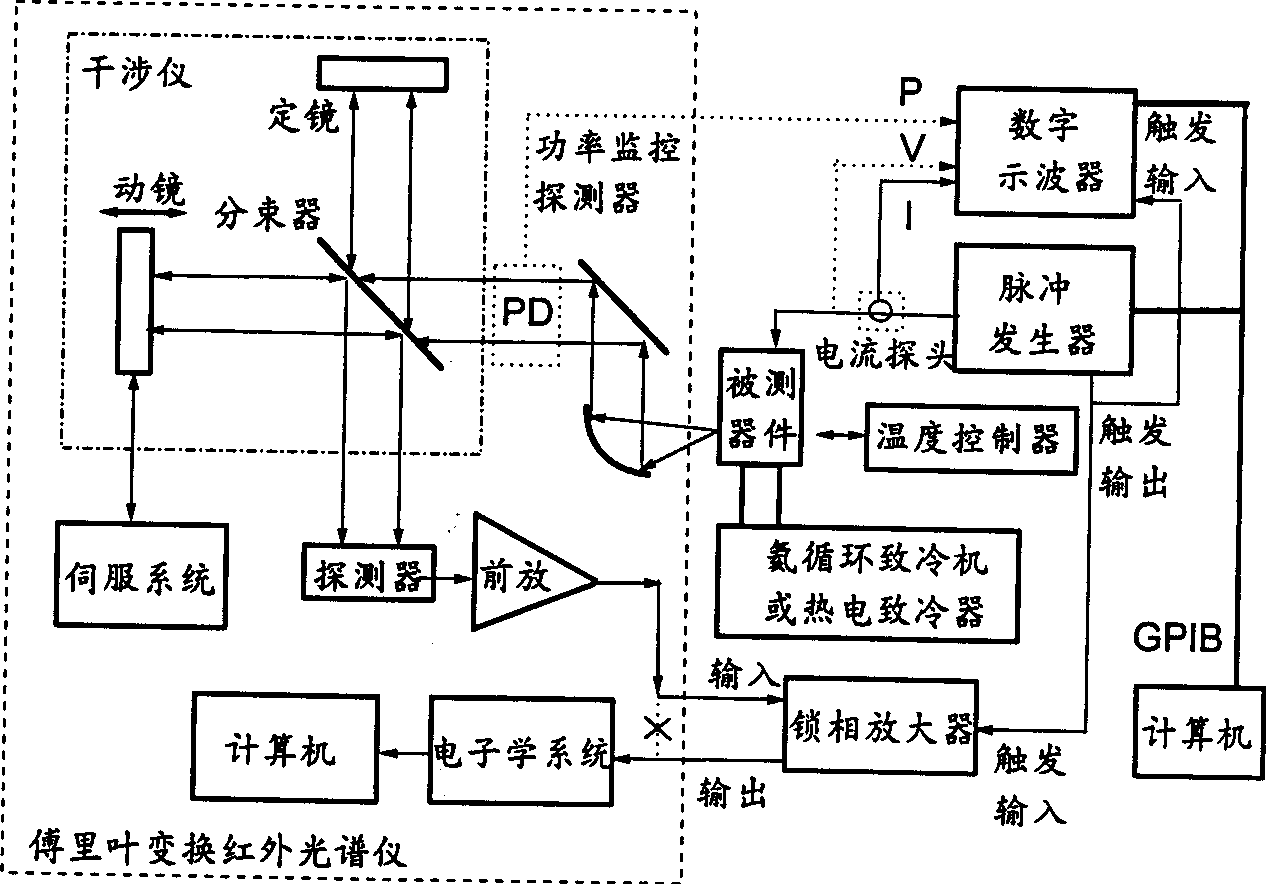

[0032] Example 1 Measurement of 2μm band AlGaAsSb / InGaAsSb multi-quantum well laser

[0033] 1. First place the laser chip on the microprobe test bench controlled by thermoelectric cooling, and directly add the driving current with the microprobe (in this embodiment, the laser is a ridge waveguide type, the waveguide width is 2.5 μm, and the cavity length is 700 μm) .

[0034] 2. Connect each hardware device according to the system block diagram. Inject liquid nitrogen into the InSb detector for cooling.

[0035] 3. Turn on the power of the computer, digital oscilloscope, pulse signal generator, FTIR spectrometer, lock-in amplifier, heat sink temperature controller and other equipment.

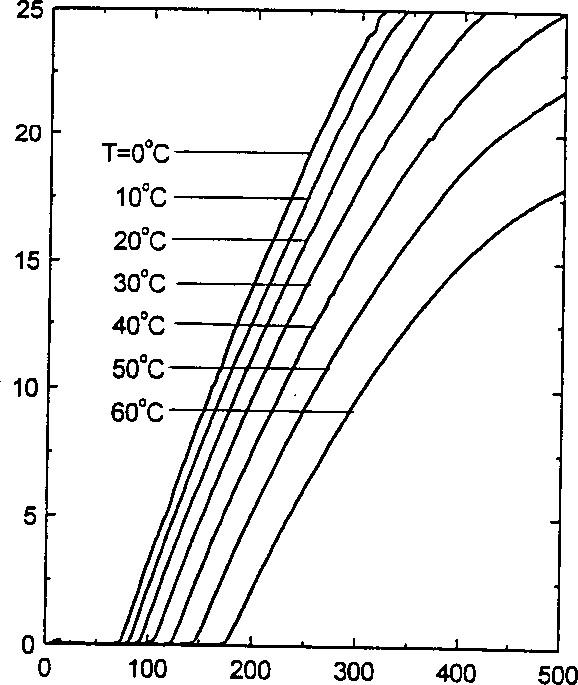

[0036] 4. Adjust the temperature of the heat sink to the required temperature (0-60°C in this embodiment, step by 10°C).

[0037] 5. Run the system control software on the computer to initialize the experimental conditions (that is, set the pulse width, period, measurement parameters of the...

Embodiment 2

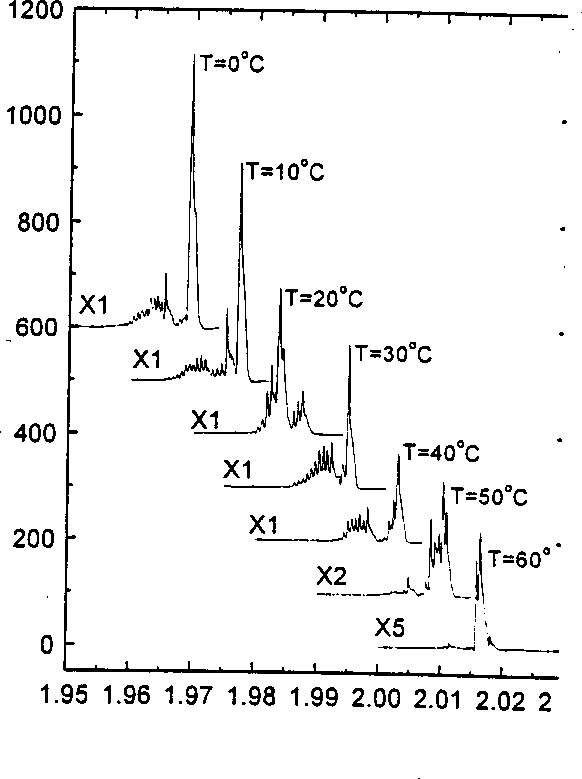

[0041] 9, fixed drive condition (in the present embodiment, drive current is 200mA, and pulse width is 1 μ s, and cycle is 100KHz), and the lasing spectrum under each condition is recorded by FTIR spectrometer as follows image 3 . Example 2 Measurement of 8 μm band InAlAs / InGaAs / InP quantum cascade laser

[0042] 1. Install the packaged laser chip on the cold head of the helium compression cycle refrigerator, connect the drive line, seal the outer cavity and evacuate it, and start cooling.

[0043] 2. Connect each hardware device according to the system block diagram. Inject liquid nitrogen into the HgcdI detector for cooling.

[0044] 3. Turn on the power of the computer, digital oscilloscope, pulse signal generator, FTIR spectrometer, lock-in amplifier, heat sink temperature controller and other equipment.

[0045] 4. Adjust the temperature of the heat sink to the desired temperature (20-200K in steps of 30K in the embodiment).

[0046] 5. Run the system control softwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com