Aeolotropic conductive film

A conductive thin film, anisotropic technology, applied in conductive connections, conductors, circuits, etc., to solve problems such as gaseous silicon generation, contamination of electronic components, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The polycarbodiimide copolymer of formula (I) can be prepared, for example, by reacting polyalkylene carbonate diol with excess aromatic diisocyanate (i.e., carrying out urethanation between hydroxyl and isocyanate), followed by addition of mono Isocyanate is bonded to the end of the repeating structure, and the aromatic diisocyanate component is carbodiimidized using a carbodiimidization catalyst in the reaction system.

[0026] The above reaction is usually carried out in a suitable solvent. Usable solvents include alicyclic hydrocarbon solvents such as cyclohexane; aromatic hydrocarbon solvents such as benzene, toluene, ethylbenzene, xylene, and cumene; alicyclic ethers such as tetrahydrofuran and dioxane; and ketone solvents such as Acetone, methyl ethyl ketone, methyl isobutyl ketone, and cyclohexanone. These solvents may be used alone or in combination of two or more.

[0027] The reaction between polyalkylene carbonate diol and aromatic diisocyanate is usually ...

Embodiment 1

[0070] A mixture of toluene diisocyanate (2,4-toluene diisocyanate (2,4-TDI) and 2,6-toluene diisocyanate (2,6-TDI) (2,4-TDI:2,6-TDI=2: 8 (molar ratio)) (100g) and polyhexamethylene carbonate diol (100g), in a mixed solvent (100g) of xylene and cyclohexane, reacted at 100°C for 3 hours, and carried out urethanation reaction Subsequently, 3-methyl-1-phenyl-2-phosphine-1-oxide (0.883 g) and p-isopropylphenylisocyanate (6.47993 g) were added, followed by polymerization at 100° C. for 1 hour, A polycarbodiimide copolymer solution obtained from the copolymerization reaction of polyhexamethylene carbonate was produced, which was dried at 90°C for 30 minutes and at 200°C for 30 minutes to produce a thin film collecting polycarbodiimide Imine copolymer solid. The glass transition temperature of the solid was determined to be 130° C. The number average molecular weight of the solid was determined to be 6300.

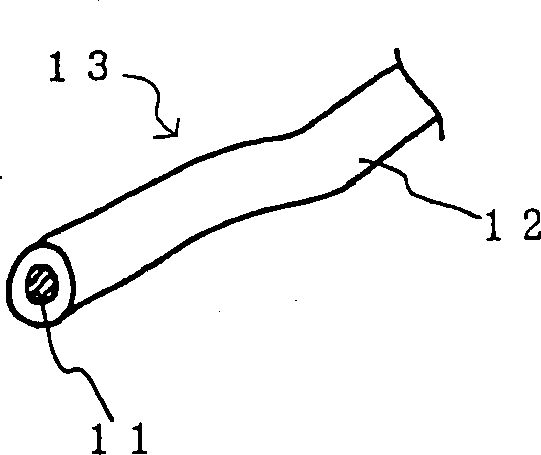

[0071] A copper wire having a diameter of 18 µm was coated with the polycar...

Embodiment 2

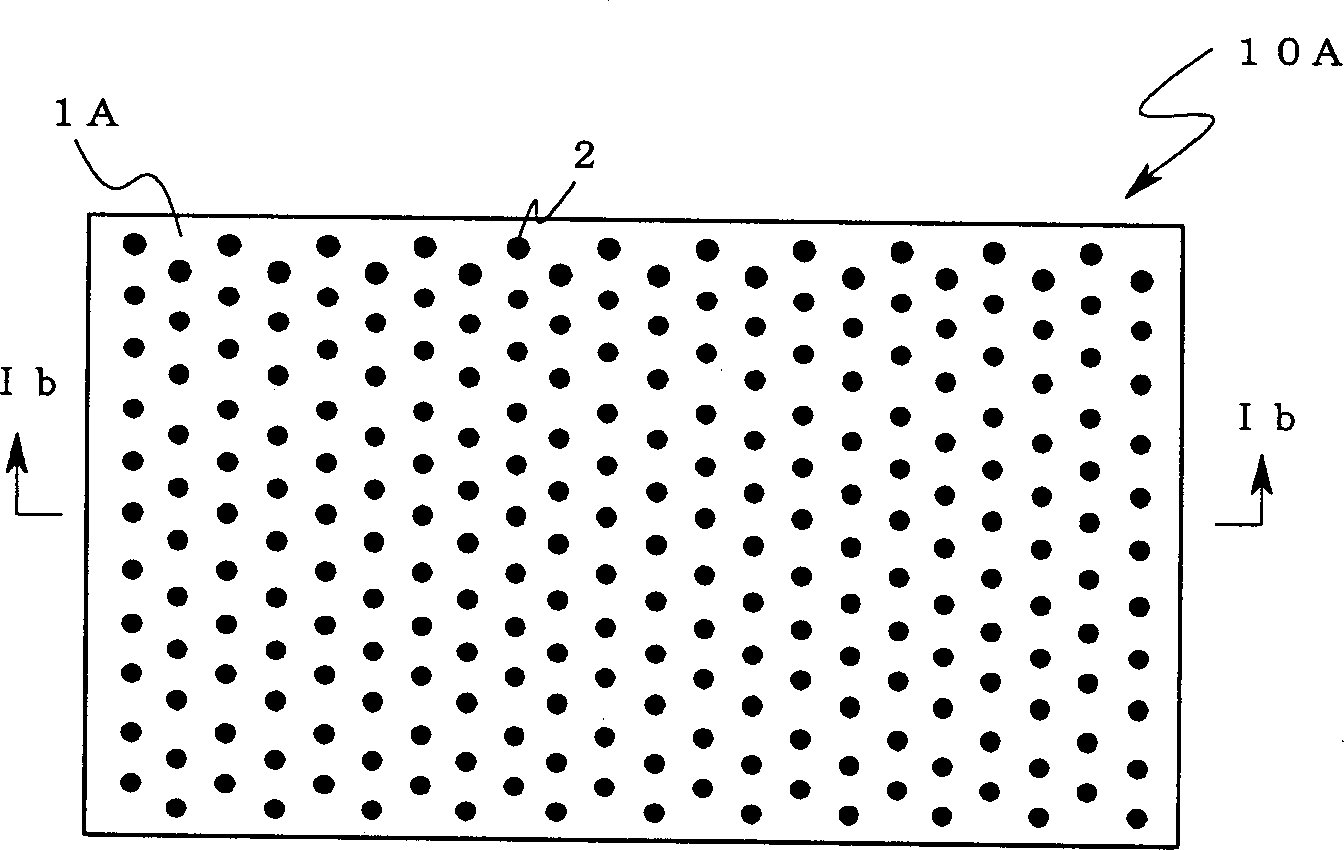

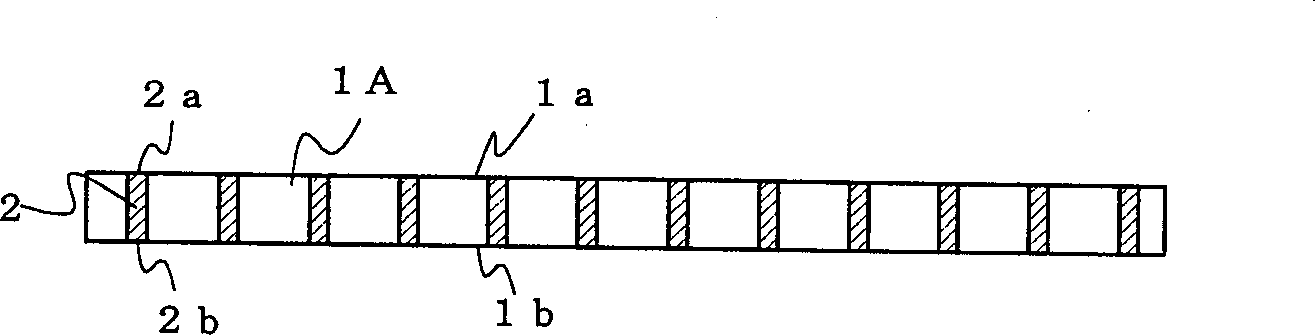

[0078] A copper wire (18 microns in diameter) was coated with the polycarbodiimide copolymer synthesized above to prepare an insulated wire. By the above-mentioned method (A), a kind of anisotropic conductive film (thickness of film: 70 microns, distance (spacing) between the centerlines of conductive channels: average 50 microns) was prepared using the insulated wires, wherein the conductive channels were arranged at the highest density, The two ends (end surfaces) of each conductive channel are in the same plane as the top surface and the back surface of the film substrate, as shown in FIG. 1 . In the preparation stage, in order to melt the coating of the insulated wire to obtain the mass of the roll, the temperature was raised at a rate of 10°C / min and kept constant for 0.5 hours after reaching 200°C, and then the roll was cooled to room temperature. It was determined that the elastic modulus at 150° C. of the thus prepared anisotropic conductive film was 200 MPa.

[0079]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com