Desalting and concentrating of oligopeptide solution by nano filtering technology

A technology of oligopeptide and solution, which is applied in the field of protein and peptide purification and concentration, to achieve the effect of simple process, good effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

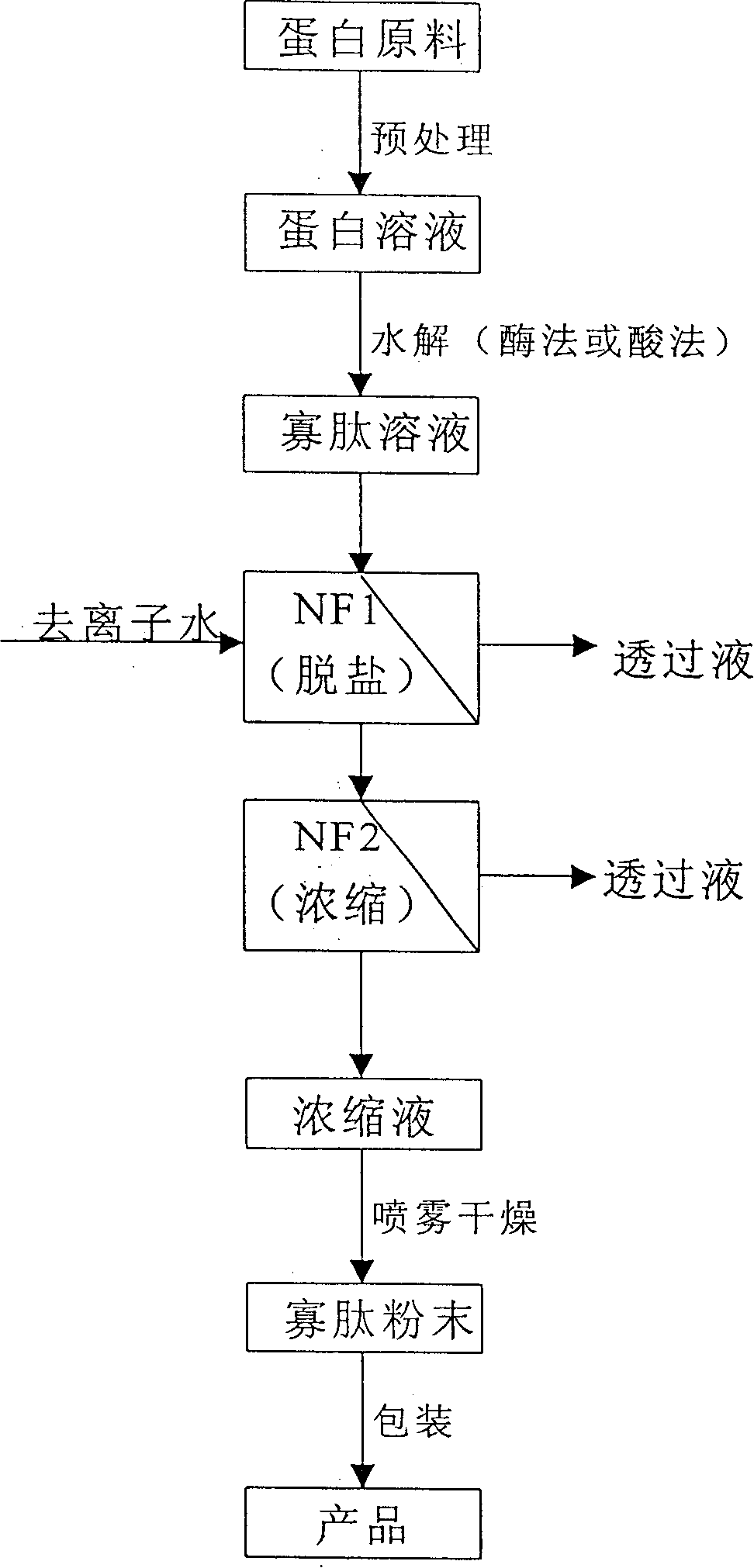

Method used

Image

Examples

Embodiment 1

[0016] Soybeans are used as raw materials to be processed, deoiled, degreased, water extracted, bean dregs removed, acid precipitated, whey removed, separated to obtain soybean protein, and dissolved in water to obtain a protein solution. Add sodium hydroxide solution to adjust the pH value, add protease to carry out enzymatic hydrolysis reaction, control the degree of hydrolysis, heat to inactivate the enzyme, centrifuge and filter to obtain the filtrate, which is the oligopeptide solution. Use the polyamide nanofiltration membrane to desalinate by intermittently adding deionized water to the concentrated solution circulation mode, the operating pressure is 1.5-1.7MPa, the operating temperature is 40-50°C, stop adding deionized water after the desalination rate reaches 90%, and concentrate to 30 % (W / W). The desalted concentrated solution is spray-dried to obtain the soybean peptide powder.

Embodiment 2

[0018] Corn gluten flour (CGM) is obtained by drying the protein waste water separated from starch in the process of corn wet milling with corn as raw material. After adding water to CGM, heat it to 95°C and keep it warm to obtain a protein solution. Add NaOH solution to adjust the pH value. , add protease to carry out enzymatic hydrolysis reaction, control the degree of hydrolysis, heat to inactivate the enzyme, centrifuge, and suction filter to obtain the filtrate, which is the oligopeptide solution. Carry out desalination and concentration with polyethersulfone nanofiltration membrane, desalination and concentration mode are the same as embodiment 1, operating pressure 1.6~1.8MPa, operating temperature 40~50 ℃, desalination rate is 95%, corn peptide solution is concentrated to 35% (W / W). After desalination, the concentrated solution is spray-dried to obtain the product corn peptide powder.

Embodiment 3

[0020] Casein phosphopeptide (CPP) is a phospho-seryl-containing peptide obtained from casein as a raw material, hydrolyzed by enzymes, and then separated and purified. Add water to the casein to obtain a casein solution, add Alcalase enzyme to carry out enzymatic hydrolysis reaction, and use the pH-stat method to control the degree of hydrolysis (DH) = 20%. Inactivate the enzyme, after centrifugation and suction filtration, the filtrate is obtained as a casein oligopeptide solution, which is desalted and concentrated with a sulfonated polysulfone nanofiltration membrane. The desalination and concentration method is the same as in Example 1. At ~45°C, the desalination rate is 90%, and the casein phosphopeptide solution is concentrated to 40% (W / W). After desalination, the feed solution is spray-dried to obtain casein phosphopeptide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com