Thrombus filter capable of realizing delayed recovery and preparation method of thrombus filter

A medical device and hemocompatibility technology, applied in the field of thrombus filters and thrombus filters that can be recovered after a delay, can solve the problems of filter displacement, filter endothelialization or tissue hyperplasia, thrombosis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

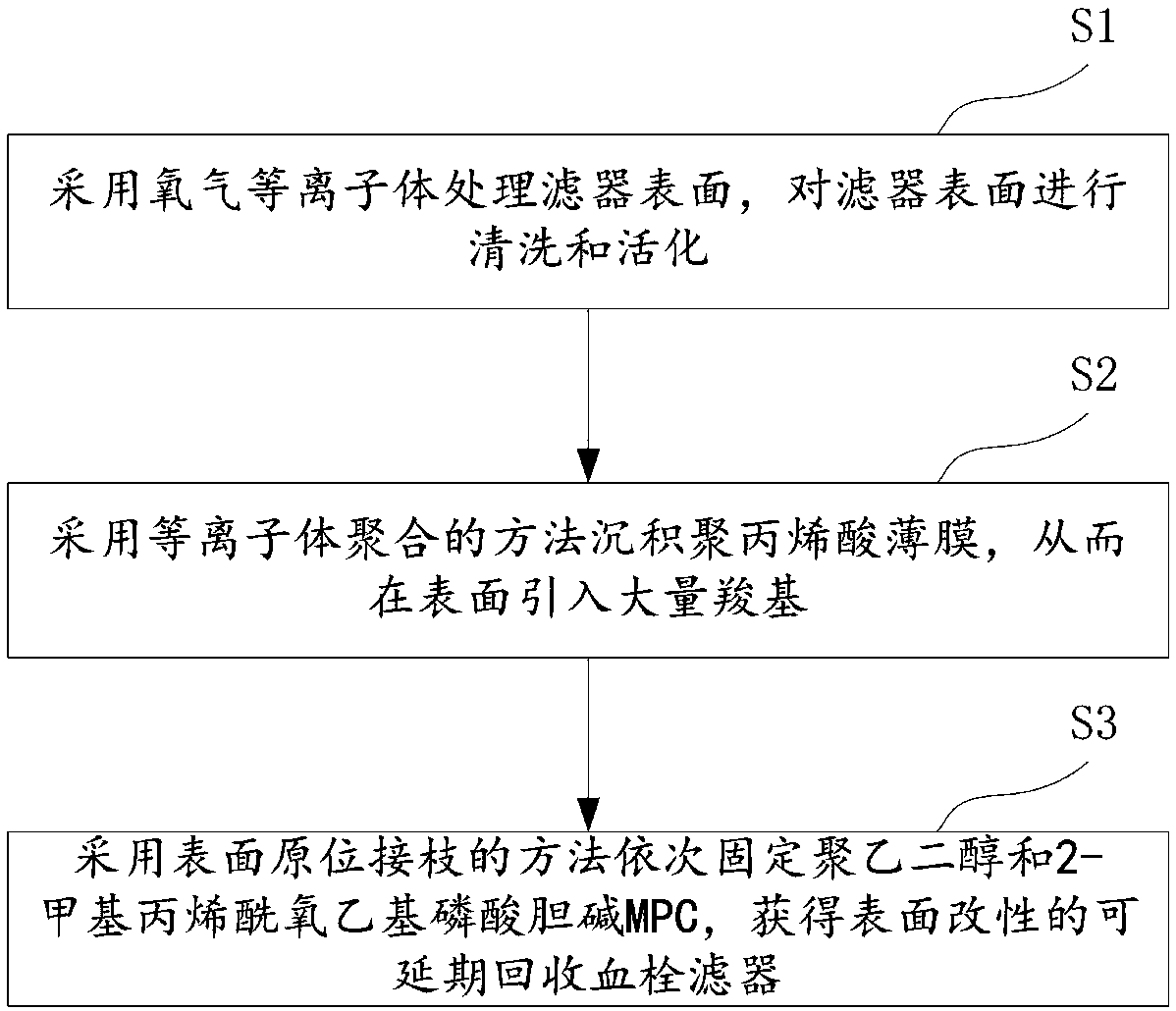

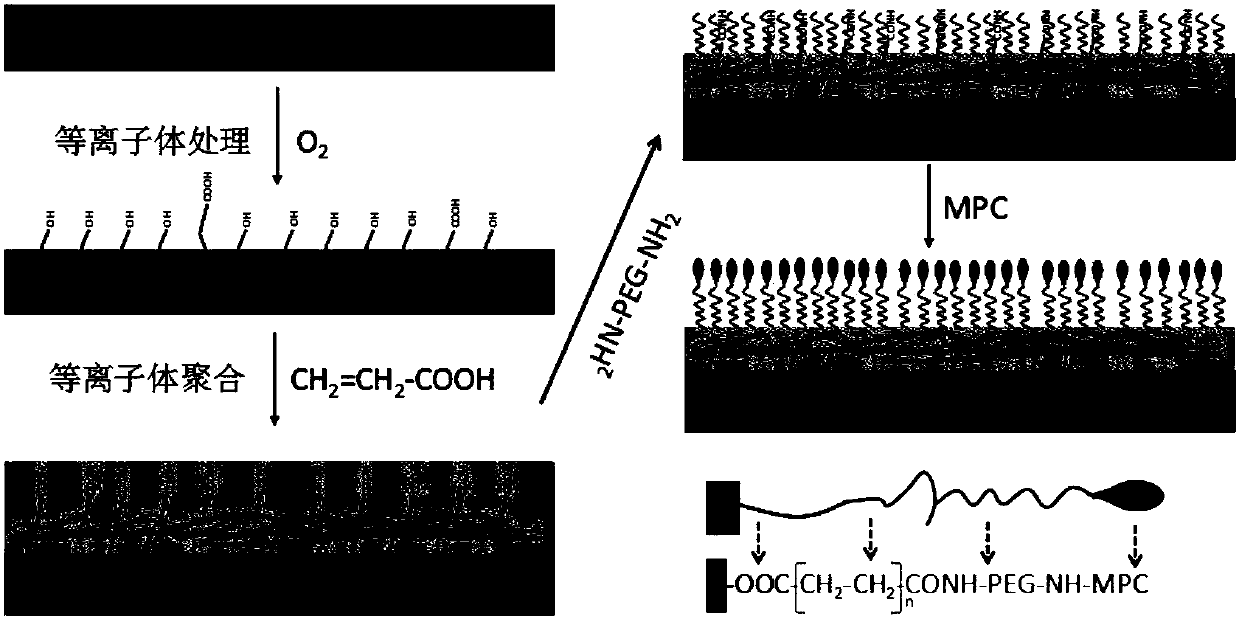

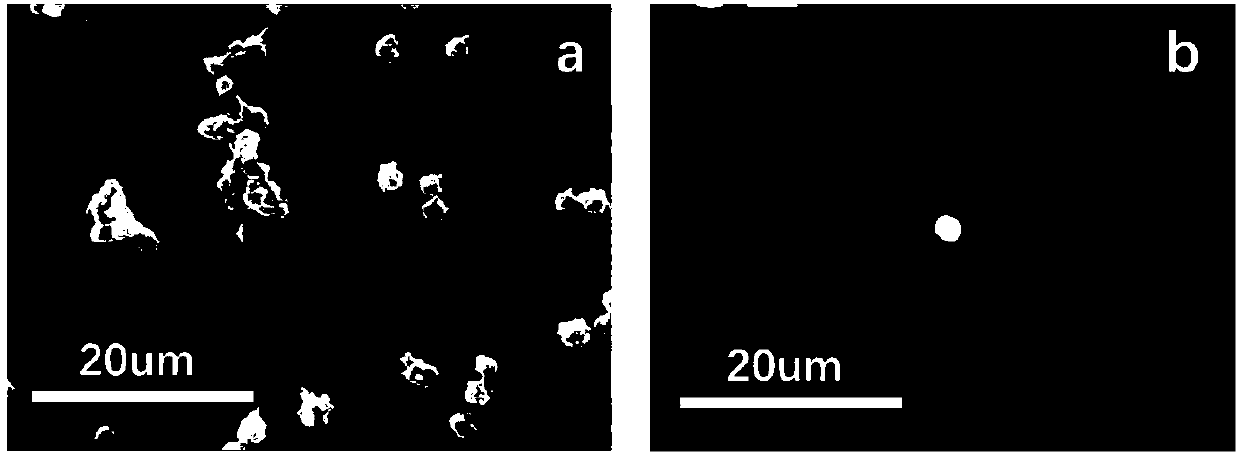

[0104] In the method for preparing the medical device with the blood compatibility coating provided by the invention, the polyacrylic acid coating is deposited by plasma polymerization, which greatly increases the carboxyl content on the filter surface, which is beneficial to improve the grafting of polyethylene glycol and MPC Density, to better stop thrombus formation and tissue growth. Moreover, fixing polyethylene glycol and MPC is a chemical reaction using terminal groups, which does not affect the biological activity of polyethylene glycol and MPC, thereby better inhibiting thrombus formation and cell growth.

[0105] Due to the oxygen plasma cleaning and activation treatment of the filter before the deposition of polyacrylic acid, the polyacrylic acid coating on the surface has a strong binding force, and the subsequent polyethylene glycol and PMC fixation adopts a covalent fixation method, which has a firm binding force and can be more function for a long time.

Embodiment 1

[0107] Embodiment 1: according to the following steps, the instrument surface is processed:

[0108] (1) Surface cleaning and activation: Firstly, ultrasonically clean the nickel-titanium alloy device samples sequentially with acetone, ethanol and distilled water, put the dried samples into a plasma processor, evacuate to below 1Pa, and charge and discharge high-purity oxygen 3 times. Pass through the sample at 2L / min, set the radio frequency discharge power to 100W, treat with oxygen plasma for 10min, and then fully wash with distilled water and dry.

[0109] (2) Surface plasma polymerization deposition of polyacrylic acid film: put the instrument sample after oxygen plasma treatment into a vacuum chamber, evacuate to below 1Pa, pass in 1L / min of acrylic acid gas, 50W radio frequency discharge, and polymerize and deposit for 30min to obtain A device sample with a polyacrylic acid film deposited on its surface.

[0110] (3) Surface-grafted polyethylene glycol: wash the instru...

Embodiment 2

[0112] Embodiment 2: Process the surface of the thrombus filter according to the following steps

[0113] (1) Surface cleaning and activation: The prepared thrombus filter was firstly ultrasonically cleaned with acetone, ethanol and distilled water in sequence, and the dried sample was placed in a plasma processor, vacuumed to below 1Pa, and filled with high-purity oxygen for 3 times. Pass through the sample at 3L / min, set the radio frequency discharge power to 200W, and treat with oxygen plasma for 20min, then fully wash with distilled water and dry.

[0114] (2) Polyacrylic acid film deposited by surface plasma polymerization: put the thrombus filter treated with oxygen plasma into a vacuum chamber, evacuate to below 1Pa, pass in 2L / min of acrylic acid gas, 80W radio frequency discharge, and polymerize and deposit for 45min to obtain A thrombus filter with a polyacrylic acid film deposited on its surface.

[0115] (3) Surface-grafted polyethylene glycol: Wash the thrombus f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com