Laser-inducing preparation of size-controllable high-density nano silicon quanta array of points

A nano-silicon quantum dot, laser-induced technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of high cost, achieve the effect of reducing interface state density, strong controllability, and avoiding high temperature treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

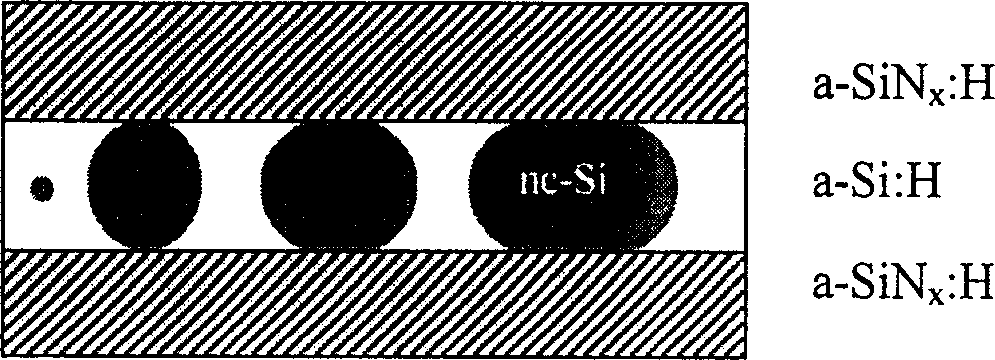

[0026] 1. a-Si:H / a-SiN x : Preparation of H multilayer modulation structure

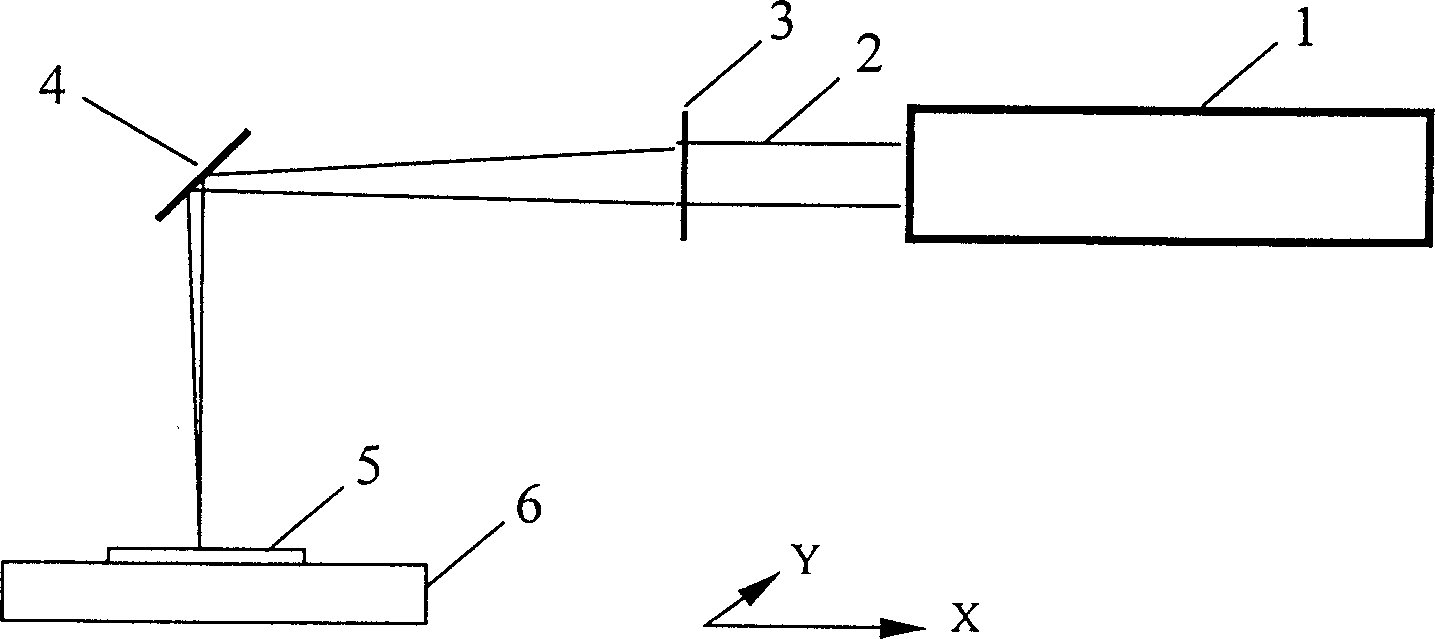

[0027] Using computer-controlled plasma-enhanced vapor deposition (PECVD) technology, using silane (SiH 4 ), ammonia (NH 3 ) and argon (Ar) as the reaction gas source; depositing a-Si: H / a-SiN on single crystal silicon wafers and quartz or optical glass substrates x : H three-layer or multi-layer modulation structure. Concrete process conditions during preparation are as follows:

[0028] Power source frequency: 13.56MHz

[0029] Power density during deposition: 0.2-0.3W / cm 2

[0030] Reaction chamber pressure: 33-40Pa

[0031] Substrate temperature: 250°C

[0032] When depositing the amorphous silicon (a-Si:H) sublayer, the SiH 4 +Ar is produced by glow decomposition reaction, where SiH 4 The flow rate is 8sccm (standard cubic centimeter per minute), and its deposition rate is 0.10nm / s; the amorphous silicon nitride (a-SiN:H) subl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com