Process for preparing titanium sponge from titanium oxide composite ore

A composite ore and titanium oxide technology, which is applied in the field of pure metal preparation by electrolysis, can solve the problems of discontinuous production, high power consumption, and technical difficulty, and achieve the effects of reducing harsh requirements, continuous production, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

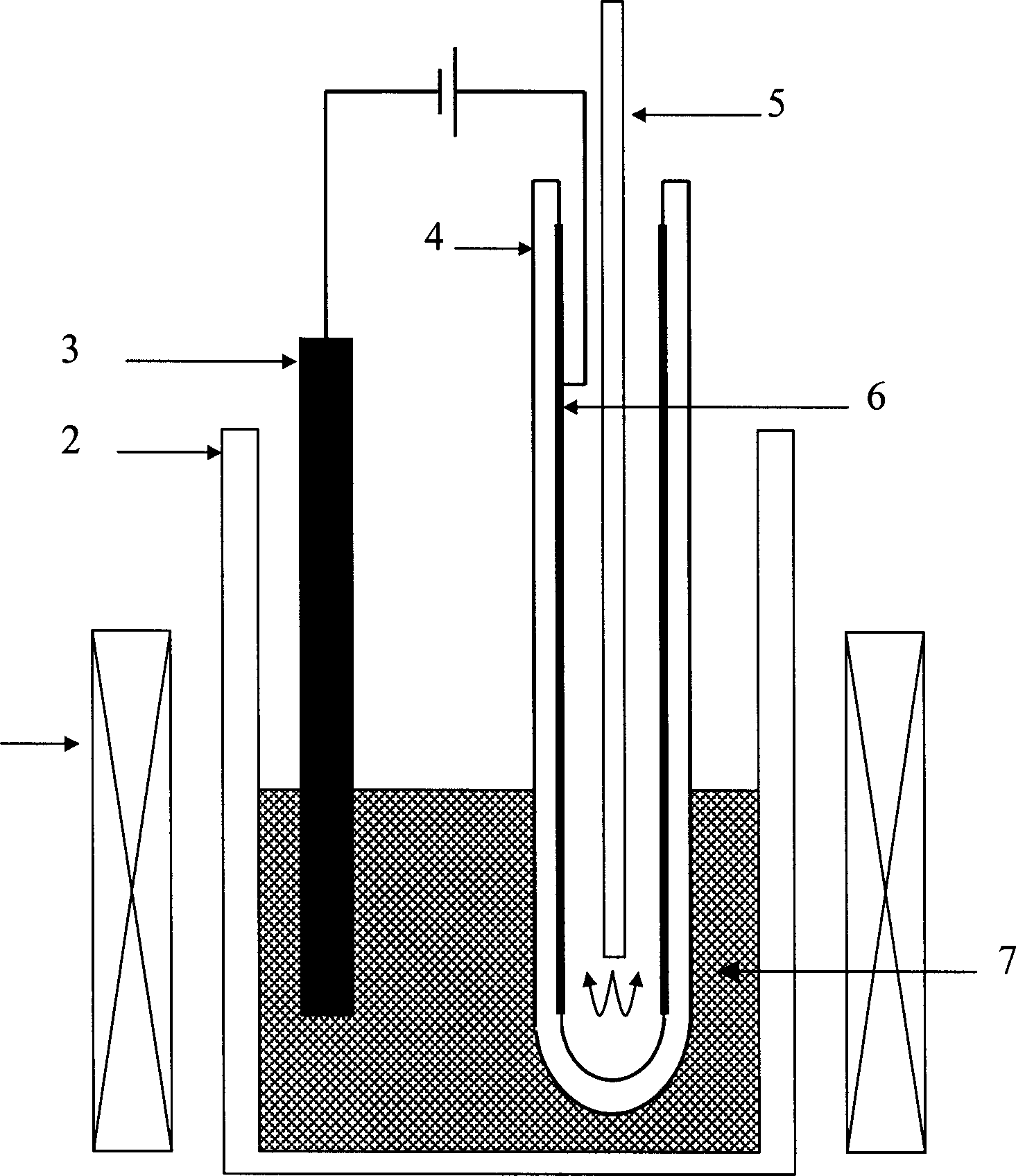

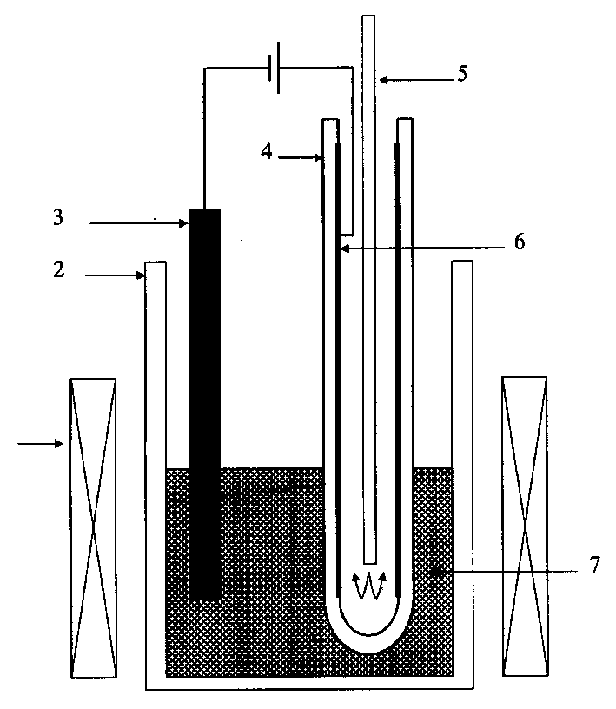

[0012] Embodiment one: the compound ore raw material that will contain titanium dioxide, i.e. TiO 2 35% perovskite (CaO.TiO 2 ) 20 grams are melted in 80 grams of NaCl-NaF-KCl molten salt system under the high temperature condition of 1000 ℃, and its composition mass ratio is 40%-40%-20%, and heat preservation 3 hours, make system composition uniform; The graphite cathode and the tubular solid oxygen-permeable membrane whose inner surface is covered with a porous cermet coating as the anode are inserted into the above-mentioned mixed molten salt in the crucible, and the anode is Ni-ZrO 2 Porous cermet coating, solid oxygen permeable membrane is yttrium stabilized zirconia, namely 0.88ZrO 2 -0.12Y 2 o 3 The flow rate of feeding hydrogen in the high-temperature ceramic tube at the anode end is 300ml / min, and the positive and negative poles of the DC power supply are connected with the positive and negative poles in the electrolytic cell respectively, so that the electrolytic ...

Embodiment 2

[0013] Embodiment two: the compound ore raw material that will contain titanium dioxide, i.e. TiO 2 35% perovskite (2FeO.TiO 2 ) 10 grams are dissolved in 80 grams of NaCl-Na under the high temperature condition of 1100 ℃ 3 AlF 6 In the molten salt system, the composition mass ratio is 20%:80%, and it is kept warm for 2 hours to make the system components uniform; the graphite cathode and the tubular solid oxygen-permeable membrane whose inner surface is covered with a porous cermet coating as the anode are inserted together In the above-mentioned mixed molten salt in the crucible, used material is identical with last example. The flow of hydrogen into the high-temperature ceramic tube at the anode end is 300ml / min, and the positive and negative poles of the DC power supply are respectively connected to the anode and cathode in the electrolytic cell to perform electrolysis operation. The electrolysis voltage is 1.25V and the electrolysis current is 0.25. A, the electrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com