Exhaust-gas purifying catalyst compound, catalyst comprising said compound and method for preparing the compound

A technology for purifying exhaust gas and catalysts, applied in the direction of catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as difficult effects, and achieve the effect of simplifying the preparation method and low affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

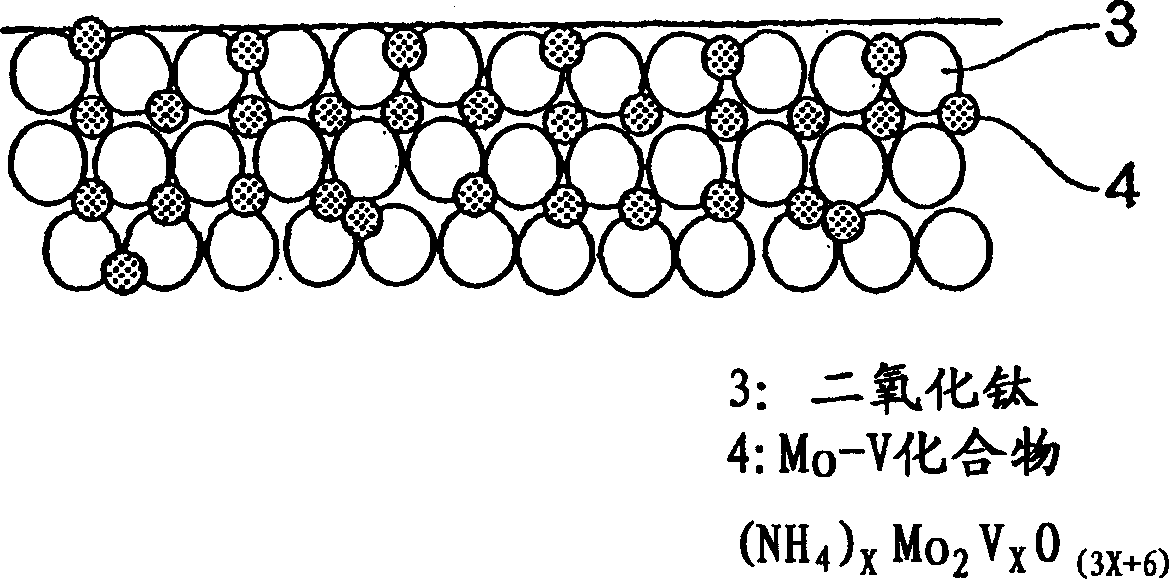

[0051] By adding 40.6g molybdenum trioxide (MoO 3 ) and 49.4g ammonium metavanadate (NH 4 VO 3 ) The resulting slurry was gently stirred at room temperature for 20 hours to allow the two compounds to react with each other and dissolve completely in water. In the solution thus obtained, the concentration of the Mo-V compound was about 18% by weight, and the ratio of V atoms to Mo atoms (V / Mo) in said compound was 3 / 2. The reddish-brown substance thus formed and dissolved in water can be represented by the structural formula (NH 4 ) 3 Mo 2 V 3 o 15 To represent.

Embodiment 2

[0060] Impregnate a network with a slurry containing 40% titanium dioxide, 20% silica sol and 1% polyvinyl alcohol, and then dry it at 150°C to obtain a catalyst substrate with a certain stiffness. The network is obtained by rubbing Combined yarns each containing 1400E glass fibers with a fiber diameter of 9 μm were woven into a plain weave at a roughness of 10 yarns / inch.

[0061] On the other hand in an additional step the 1.5kg specific surface area is about 230m 2 / g of titanium dioxide was added to 75 g of oxalic acid, water was added thereto to form a paste, and then 300 g of silica·alumina fibers were added thereto and kneaded until a uniform paste was obtained.

[0062] The paste thus obtained was placed between the two catalyst substrates obtained in the above step, and they were passed through press rolls to obtain a sheet having a thickness of 0.7 mm and containing titanium dioxide. This sheet was dried at room temperature and then calcined at 400°C for 2 hours to ob...

Embodiment 3 to 6

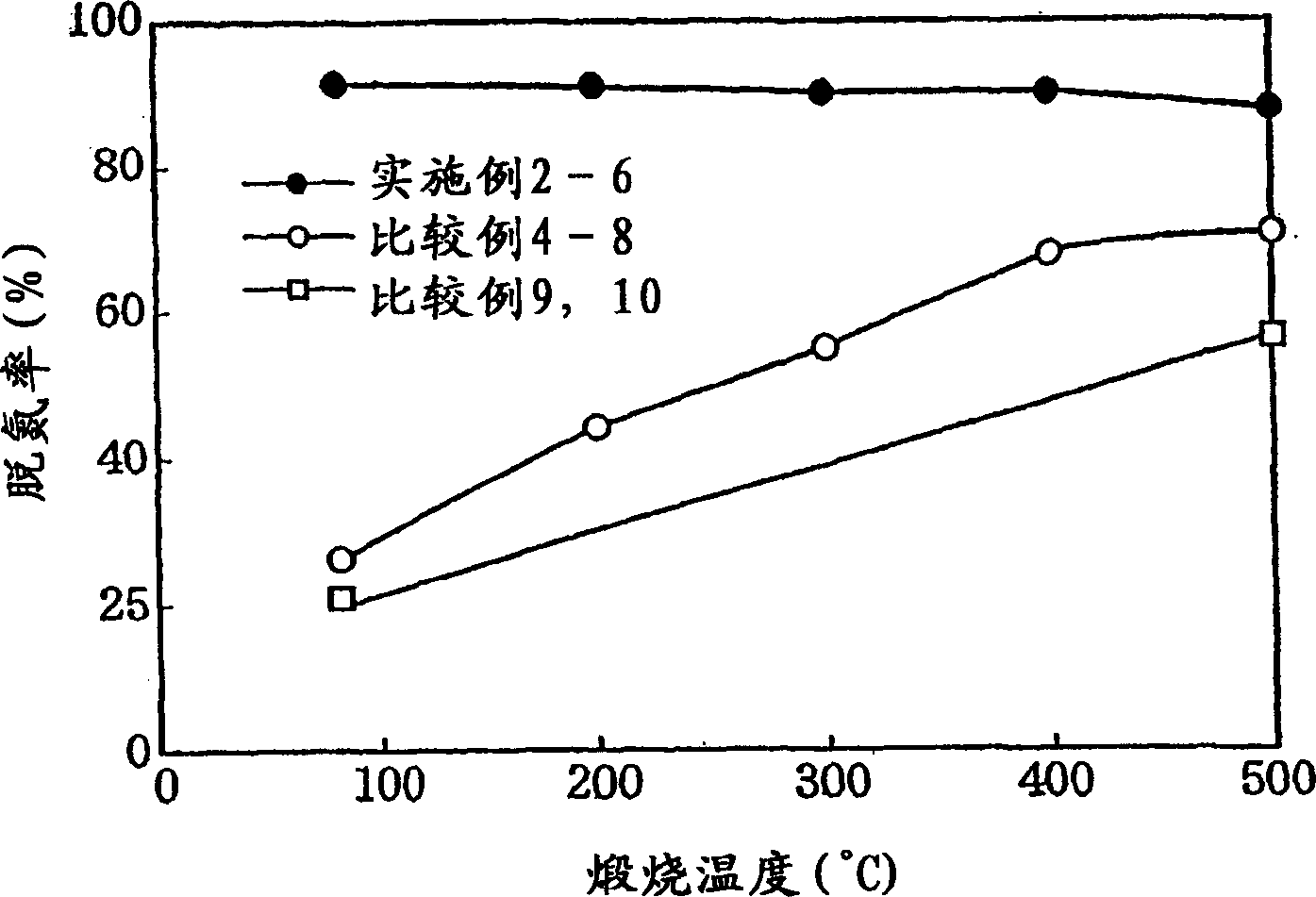

[0070] Each catalyst was prepared by calcining the same catalyst as that obtained in Example 2 at 200, 300, 400 and 500° C. for two hours, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com