Feeding spore-forming bacillus microbial preparation-glycopeptide and method for making the same

A micro-ecological preparation, Bacillus technology, applied in the direction of application, bacteria, animal feed, etc., can solve the problem of low utilization rate, achieve the effect of accelerated synthesis, rich nutrition, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

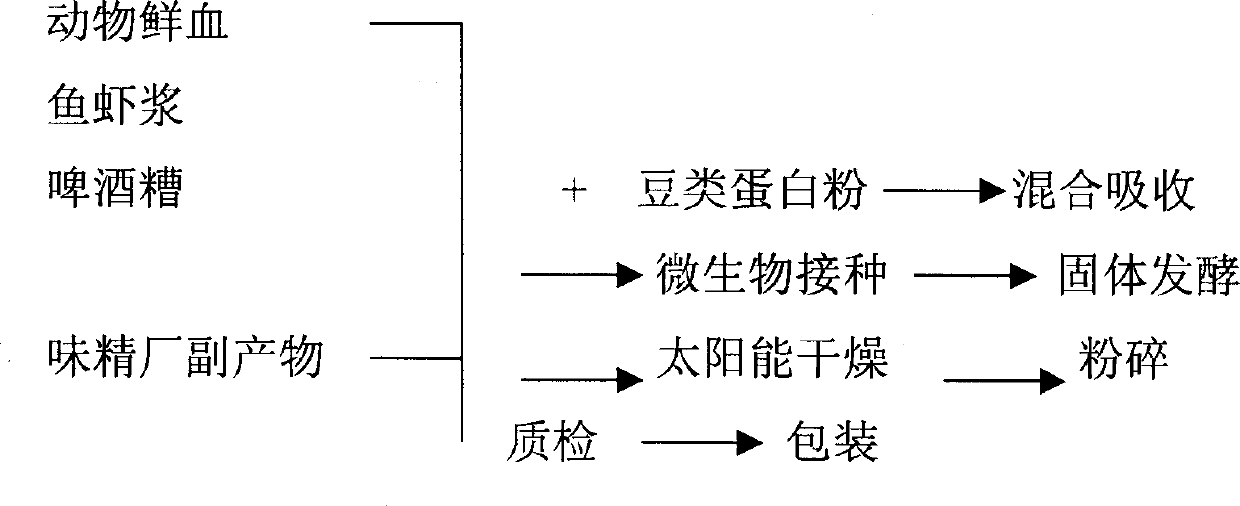

[0033] Embodiment 1: production process of cuttlefish viscera powder (see Fig. 1)

[0034] The production process of squid viscera powder is as follows:

[0035] Cook the fresh cuttlefish viscera (the temperature is controlled at 100°C-110°C for 2 hours), and after squeezing, separate the liquid (squid oil), concentrate, dissolve, and mix (loading body wheat gluten powder or wheat bran 15 %) drying (temperature controlled at 90°C-100°C, indirect steam drying for 1 hour), after cooling, remixing, sieving, inspection, and packaging.

Embodiment 2

[0036] Embodiment 2: the making of bacillus probiotics for feeding---glycopeptin (1)

[0037] Formulation (I):

[0038] Take: 1. Animal protein raw materials: 40%, of which: animal blood meal 20%, squid

[0039] Dirty powder 25%, silkworm chrysalis 15%, fish and shrimp paste 10%, slaughter by-products 30%;

[0040] 2. Vegetable protein raw materials: 60%, of which: 40% of bean protein powder, brewer's grains

[0041] 30%, 30% by-products of monosodium glutamate factory;

[0042] 3. Krill hydrolyzate: 1%

[0043] 4. Spore-type probiotics:

[0044] 5. Antioxidants: Appropriate amount

[0045] Production steps:

[0046] Mix animal protein raw materials and vegetable protein raw materials in proportion, inoculate bacillus, and carry out solid fermentation (time: 48 hours-72 hours, temperature control: 25°C-40°C, pH value 4.0-4.5. Humidity For: 45%-55%), continuous fermentation.

[0047] Concrete its process route is as follows (see Figure 2):

[0048]Bacte...

Embodiment 3

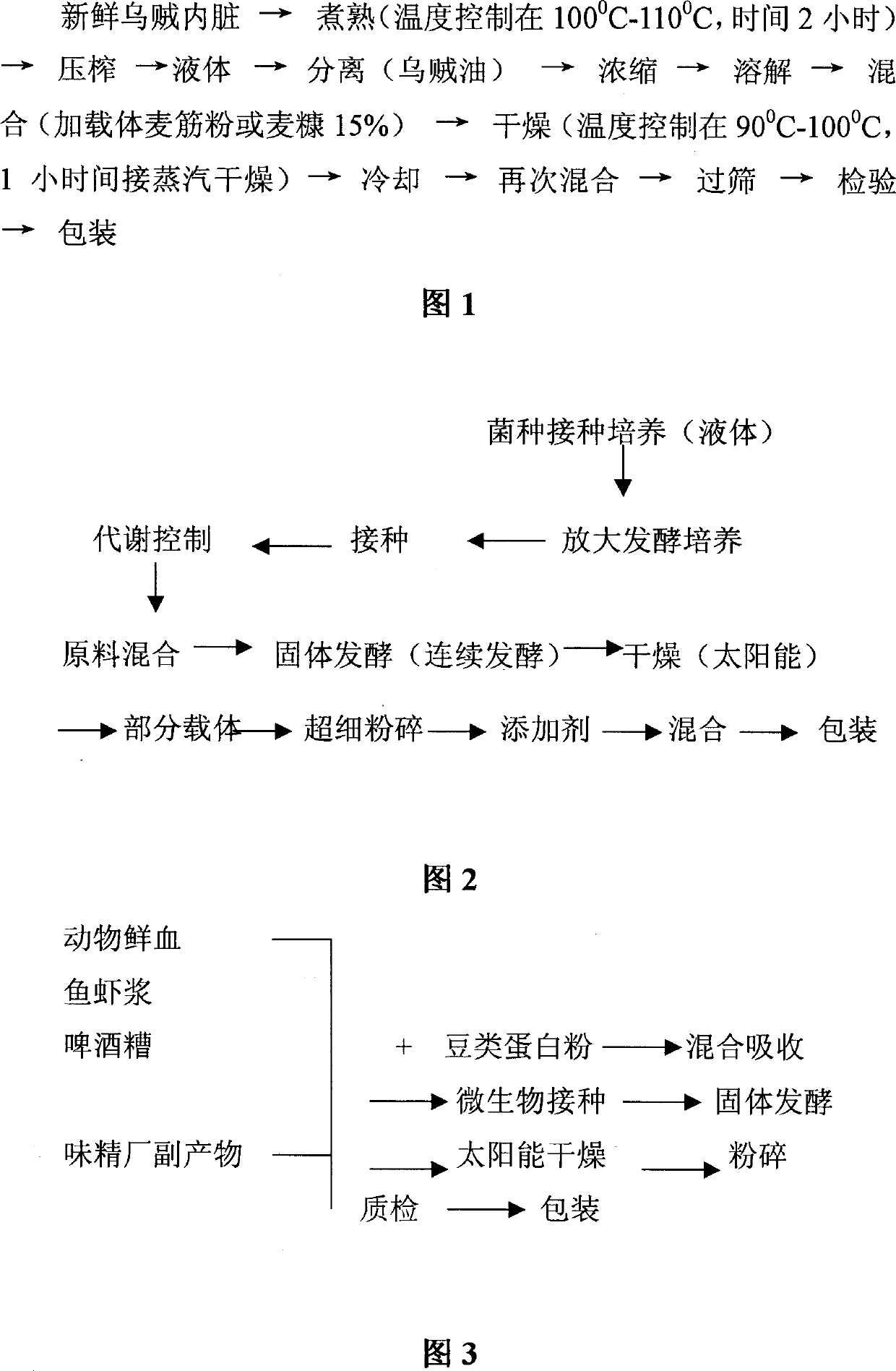

[0063] Embodiment 3: Bacillus probiotics for feeding——Glycopeptin (II)

[0064] Formulation (II):

[0065] Take: 1. Animal protein raw materials: 30%, of which: animal blood meal 15%, squid

[0066] Dirty powder 25%, silkworm chrysalis 10%, fish and shrimp paste 15%, slaughter by-products 35%;

[0067] 2. Vegetable protein raw materials: 60%, of which: bean protein powder 45%, brewer's grains

[0068] 30%, 25% by-products of monosodium glutamate factory;

[0069] 3. Krill hydrolyzate: 1%

[0070] 4. Bacillus probiotics:

[0071] 5. Antioxidants: Appropriate amount

[0072] Production steps:

[0073] Mix animal protein raw materials and vegetable protein raw materials in proportion, inoculate bacillus, and carry out solid fermentation (time: 48 hours-72 hours, temperature control: 25°C-40°C, pH value 4.0-4.5. Humidity For: 45%-55%), continuous fermentation.

[0074] Concrete its process route is as follows (see Figure 3):

[0075] Animal blood, fish and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com