Intelligent control method for aluminium oxide chamotte sintering rotary kiln

A control method and intelligent control technology, applied in rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of unstable clinker quality, difficulty in establishing mathematical models, large measurement errors, etc., and achieve long-term stability of the thermal system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

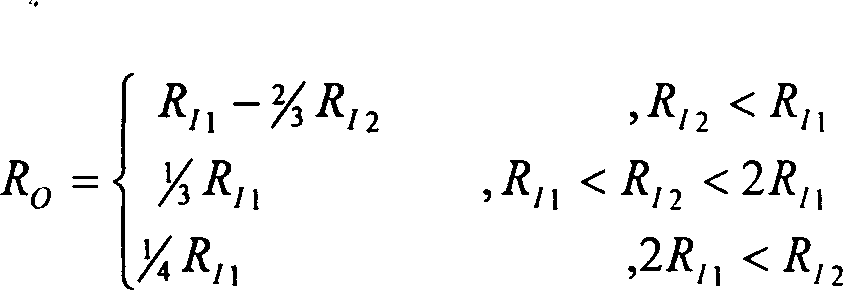

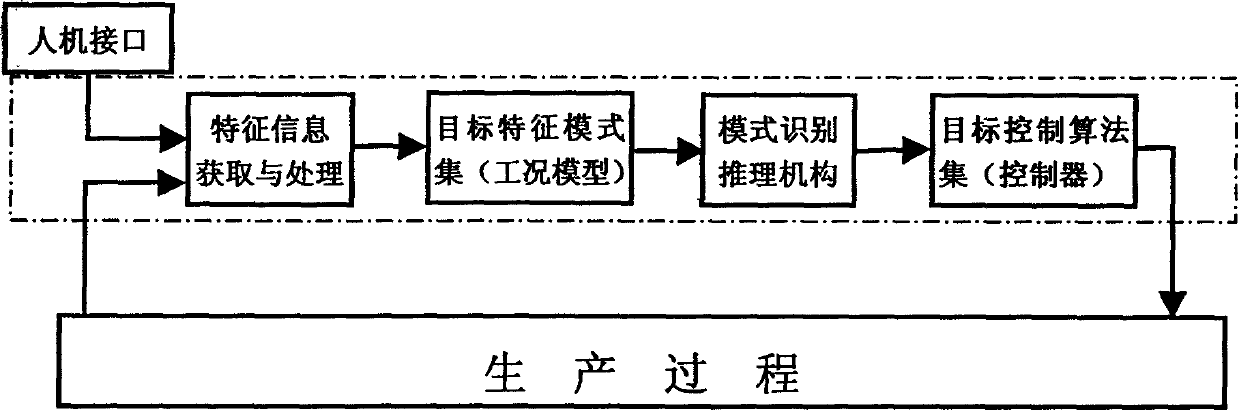

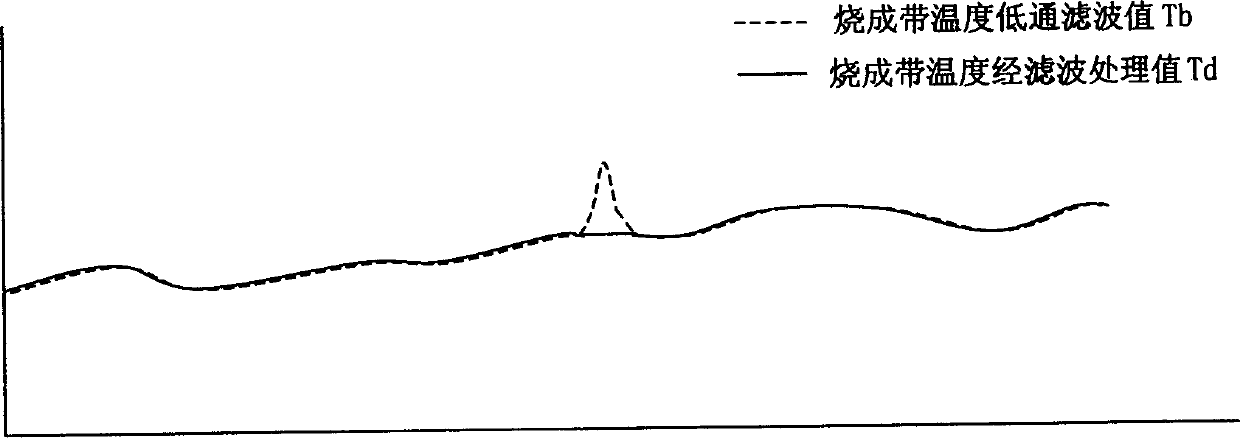

[0036] The intelligent control method of alumina clinker sintering rotary kiln, this method is to apply the control system software on the industrial control computer by using intelligent prediction, coordination, self-adaptation, multi-objective decision-making, and multi-modal control technology; this method is through the following software, It is realized by hardware control settings, which include detection instruments, actuators, and industrial control computers; software control settings—that is, control system software, which consists of feature information preprocessing, feature mode sets, control algorithm sets, reasoning mechanisms, and human-machine coordination. Interface composition; the feature information preprocessing includes firing zone temperature low-pass filtering, intelligent filtering, variable time scale processing feature information, feature data includes firing zone temperature and change, kiln tail temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com