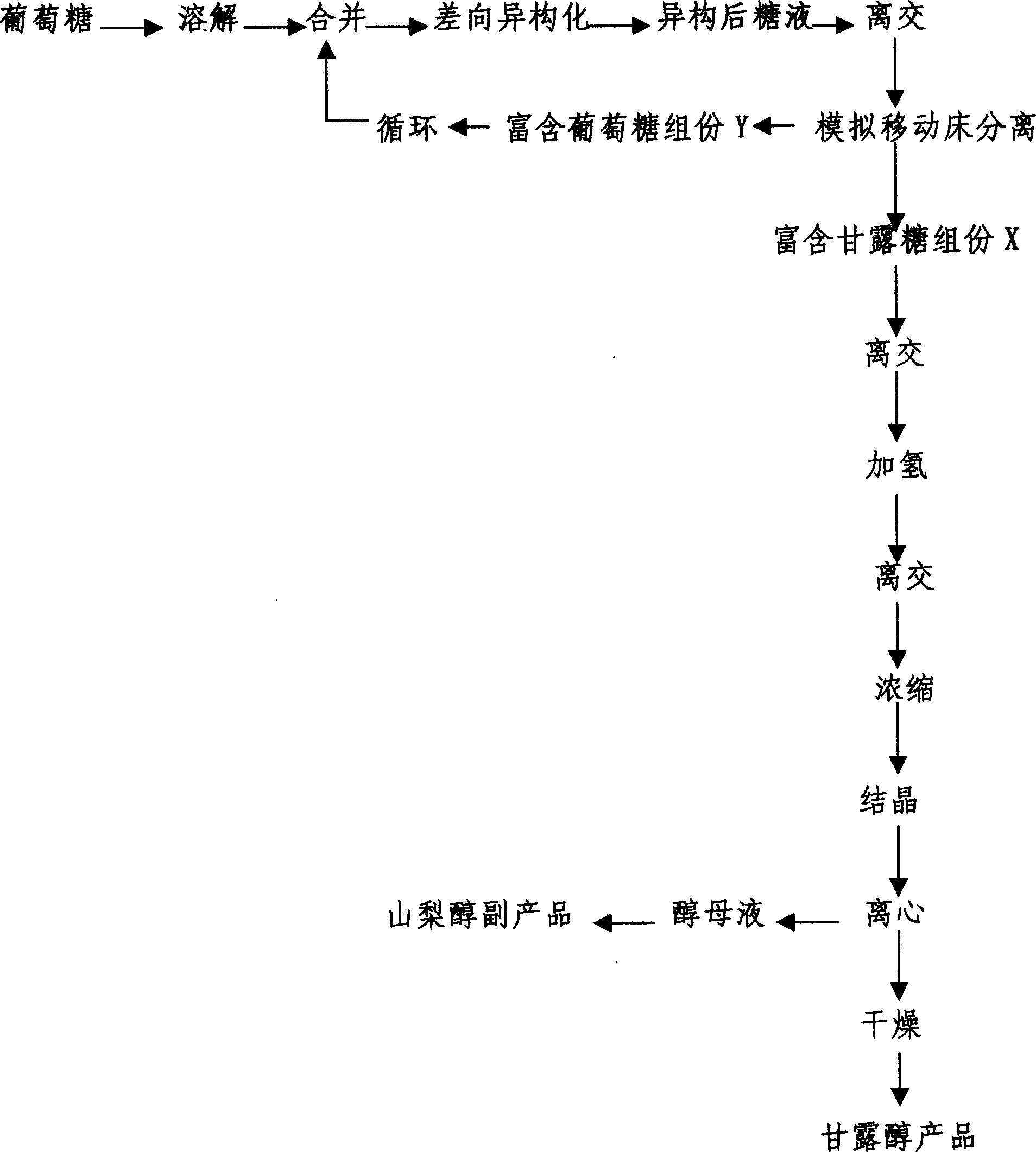

High-yield manna sugar preparation process

A preparation process, the technology of mannitol, applied in the field of preparation of organic compounds, can solve the problems of high production cost, high heat source, power consumption, high steam consumption, etc., and achieve the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1100 grams of oral crystalline glucose (containing 1 crystal water molecule, the actual glucose dry matter is 1000 grams) is dissolved in 900ml deionized water, is mixed with Bx50.30% glucose aqueous solution, adds 1.5 grams of sodium molybdate, after stirring and dissolving, use The pH value of the sugar solution was adjusted to 3.85 with hydrochloric acid, and then heated and maintained at 100° C. for 2 hours with stirring. After removing ionic impurities with cation and anion exchange resins, the sugar solution after isomerization is obtained, and the composition is as follows: mannose 30.4%, glucose 69.6%.

[0029] Mannose-glucose separation is carried out using a simulated moving bed device, the separation temperature is 58°C, calcium-type cation exchange resin is used as the adsorbent, and water is used as the eluent to continuously obtain mannose-rich components and glucose-rich components. The epimerization reaction is carried out by repeated circulation of the ...

Embodiment 2

[0032]5320 grams of isomerized sugar solution obtained after epimerization reaction, the concentration is 50%, and its chemical composition is as follows: 310 grams of mannose, accounting for 30.45%, and 1850 grams of glucose, accounting for 69.55%. Separation of mannose-glucose using a simulated moving bed device, with a feed concentration of 50%, at a separation temperature of 57°C, using calcium-type cation exchange resin as an adsorbent, water as an eluent, and passing through a 12-column simulated moving bed After the device is separated, 2900 grams of mannose-rich components are obtained, with a concentration of 32.07%, including 700 grams of mannose and 230 grams of glucose, and the content of mannose is 75.27%, which can be hydrogenated to produce mannitol; the glucose-rich component 7680 grams, concentration is 22.53%, wherein mannose 110 grams, glucose 1620 grams, mannose content is 6.36%.

[0033] Add 1020 grams of oral glucose to the above-mentioned 7680 grams of g...

Embodiment 3

[0035] After the isomerized sugar solution is separated by 24-column simulated moving bed, the mannose content in the obtained mannose-rich component is 88.8%, and the concentration is 33.66%, which is mixed with a part of the epimerized sugar solution and adjusted to The mannose content of the mixed sugar solution is 75.63%, and hydrogenation reaction is carried out after separation to produce mannitol.

[0036] material

[0037] When the mannose content in the mannose-rich component obtained after the simulated moving bed separation is too high, the mannose-rich component can be mixed with a part of the isomerized sugar solution as in Example 3 to obtain the mixed sugar The mannose content of the liquid is 75.63%, which can guarantee the hydrogenation requirement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com