Process for preparing size-controllable nano-silicon dioxide

A nano-silicon dioxide and size technology, applied in the preparation of silicon dioxide, silicon oxide, oxide/hydroxide, etc., can solve the problems of poor cooling effect, sintering into large particles, and difficult size, so as to improve the cooling effect. Efficiency and effect of preventing particle size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

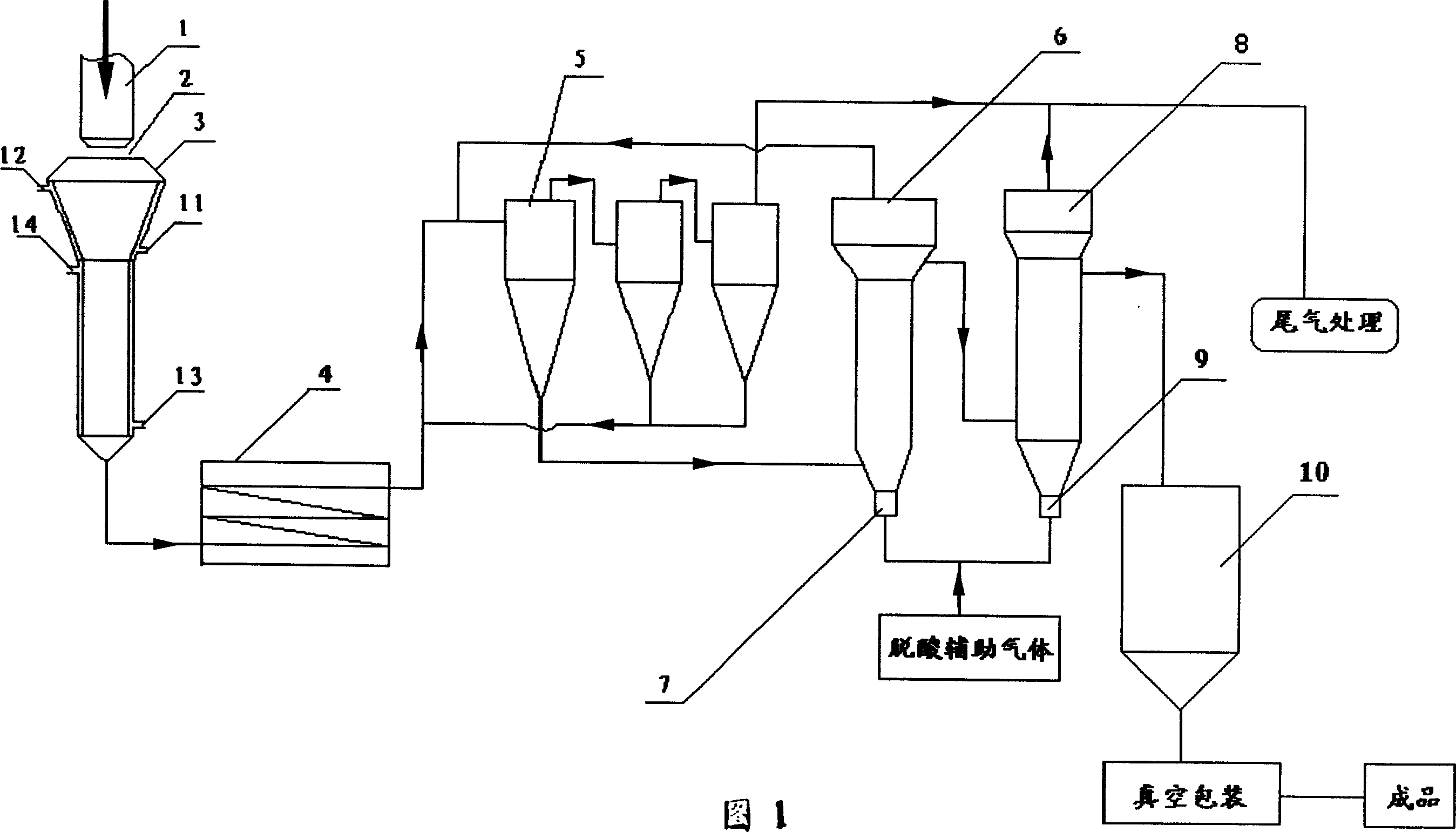

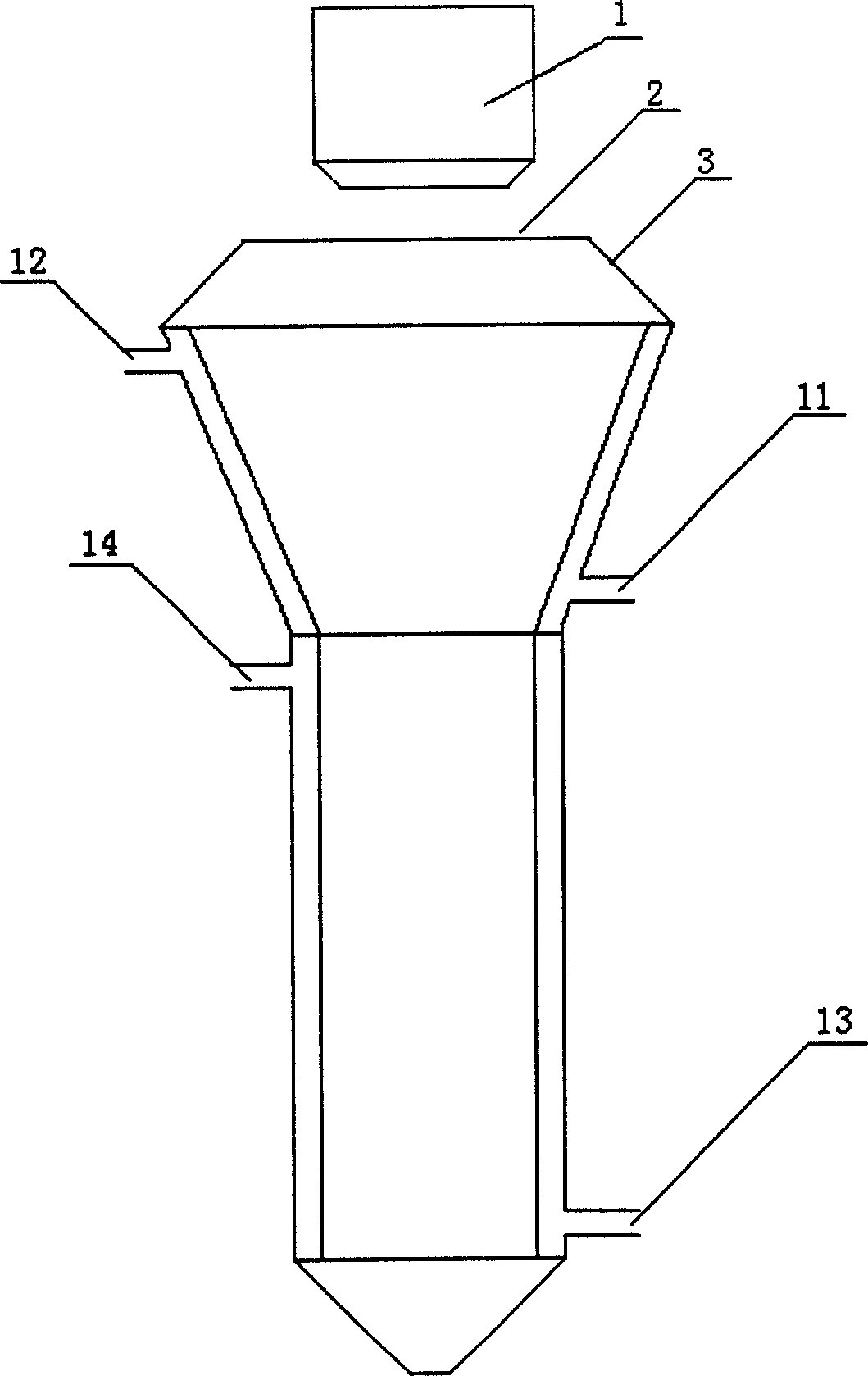

[0022] Methyltrichlorosilane at 7.5m 3 / h, hydrogen at 12m 3 / h, air at 105m 3 The supply of / h is continuously delivered to the premixer for premixing (the above volume is the standard volume), and then enters the nozzle of the combustion furnace after preheating to 120°C. The specific process is shown in Figure 1. The temperature in the reaction chamber is 720°C. The temperature in the primary deacidification furnace is 600°C, the temperature in the secondary deacidification furnace is 550°C, the auxiliary gas for deacidification is water vapor and nitrogen, and the temperature is 230°C. The quality indicators of the prepared silica are as follows:

[0023] Silica content (%) (hydrofluoric acid method) 99.85

[0024] Primary particle average particle size (nm) (electron microscope method) 30

[0025] Specific surface area (m2 / g) (BET method) 153

[0026] PH value (4% water suspension) 3.95

[0027] Carbon content (%) 0.01

Embodiment 2

[0029] The methyl trichlorosilane of embodiment 1 is replaced with silicon tetrachloride, and silicon tetrachloride is 7m 3 / h, hydrogen at 15m 3 / h, air at 130m 3 The supply of / h is supplied, the process is the same as in Example 1, and the temperature in the reaction chamber is 640° C., and the others are the same as in Example 1. The quality index of the prepared silica is as follows:

[0030] Silica content (%) (hydrofluoric acid method) 99.85

[0031] Primary particle average particle size (nm) (electron microscopy) 12

[0032] Specific surface area (m 2 / g) (BET method) 283

[0033] PH value (4% water suspension) 4.05

[0034] Carbon content (%) Not determined

Embodiment 3

[0036] The methyltrichlorosilane in Example 1 is replaced with 60% methyltrichlorosilane and 40% silicon tetrachloride, and the supply is 8.5m 3 / h, hydrogen is 16m 3 / h, the air is 125m 3 / h, the temperature in the reaction chamber is 690°C, and other process parameters are the same as in Example 1, and the quality index of the prepared silicon dioxide is as follows:

[0037] Silica content (%) (hydrofluoric acid method) 99.82

[0038] Primary particle average particle size (nm) (electron microscopy) 15

[0039] Specific surface area (m 2 / g) (BET method) 208

[0040] PH value (4% water suspension) 4.23

[0041] Carbon content (%) 0.01

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com