A diamond film flat field emission cathode and method for making same

A diamond film, emission cathode technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of low emission threshold and current density, large influence of ambient temperature, unstable emission performance, etc. To achieve the effect of simple preparation method, reduced recombination, stable and consistent emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

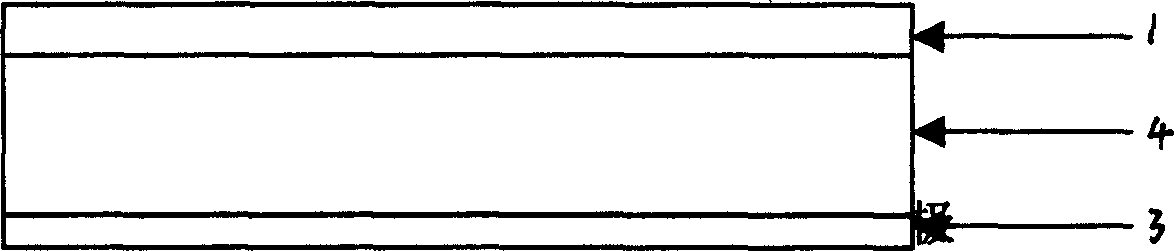

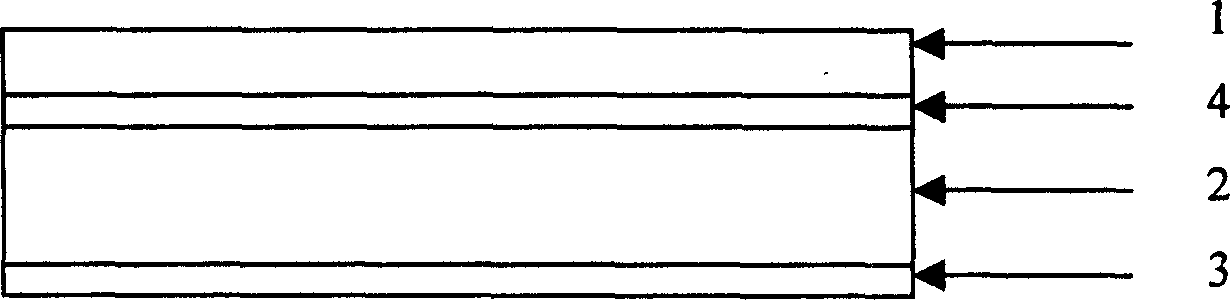

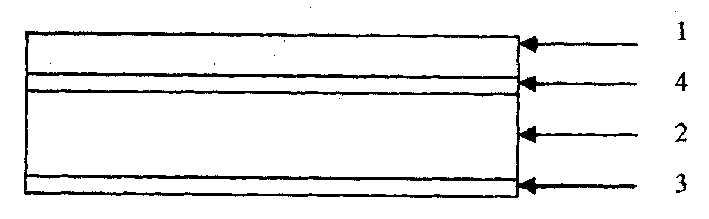

[0034] The specific structure of the diamond film planar field emission cathode of this embodiment can be found in figure 2 A polished N-type (001) single crystal silicon wafer is used as the substrate 2, and a layer of 50nm-thick metal silicide CoSi is grown on one side of the substrate 2 by the molecular beam epitaxy method. 2 4. The growth conditions are: use gas containing Si and Co as the source, and the gas pressure is 5×10 -9Toor, the substrate temperature is 500 degrees, and the growth time is 8 minutes. at CoSi 2 A diamond film 1 with a thickness of 0.5 μm is grown on the surface by a microwave plasma chemical vapor deposition method. The growth conditions are as follows: firstly, diamond nucleation is formed, a negative bias is applied at -140V, and the mixing ratio of methane / hydrogen is 10:100 by volume; The substrate temperature is 700°C, the reaction pressure is 30mbar, the microwave power is 1000W, and the nucleation time is 17 minutes; secondly, the diamond ...

Embodiment 2

[0036] The specific structure of the planar diamond film field emission cathode of this embodiment can be found in figure 2 , the substrate 2 is made of polished metal Mo, and a layer of metal silicide TiSi with a thickness of 80 nm is grown on one side of the substrate 2 by reactive sputtering method. 2 4. The growth conditions are: the substrate temperature is 850 degrees, the silicon target sputtering power is 200W, the Ti target sputtering power is 80W, the flow rate of Ar is 20sccm, and the pressure is 1×10 -2 Toor, the sputtering time is 10 minutes, the sample is taken out after sputtering, in 1:1 H 2 SO 4 and H 2 o 2 Medium corrosion for 30 minutes can obtain high-purity C54 phase TiSi 2 membrane. At TiSi 2 A diamond film 1 with a thickness of 1 μm is grown on the surface by hot filament chemical vapor deposition method. The growth conditions are as follows: first, the diamond is nucleated, the temperature of the filament is 2000 degrees, the negative bias voltag...

Embodiment 3

[0038] The specific structure of the planar diamond film field emission cathode of this embodiment can be found in figure 2 A polished N-type (001) single crystal silicon wafer is used as the substrate 2, and a layer of metal silicide FeSi with a thickness of 60 nm is grown on one side of the substrate 2 by ion implantation and annealing method. 2 4. Growth conditions: substrate temperature is 350 degrees, Fe + The injection energy is 200KV, and the metering is 2×10 17 / cm 2 , 1000 degrees annealing time 20 seconds after taking out the sample, in 1:1 H 2 SO 4 and H 2 o 2 Medium corrosion for 30 minutes, high purity FeSi can be obtained 2 membrane. In FeSi 2 A diamond film 1 with a thickness of 1 μm was grown on the surface by a hot filament chemical vapor deposition method, and the growth conditions were the same as those in Example 2. On the other side of the substrate 2, an Au / Ni electrode 3 was deposited by vacuum evaporation. The thickness of Ni was 50nm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com