Method for preparing high throughflow nanometre composite lightning arrester valve plate

A nano-composite material and surge arrester technology, which is applied in overvoltage protection resistors, varistors, etc., can solve the problems of inorganic side glaze easy to absorb moisture, large filler particle size, and high price, so as to improve the anti-high current impact performance, Improved flow capacity and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

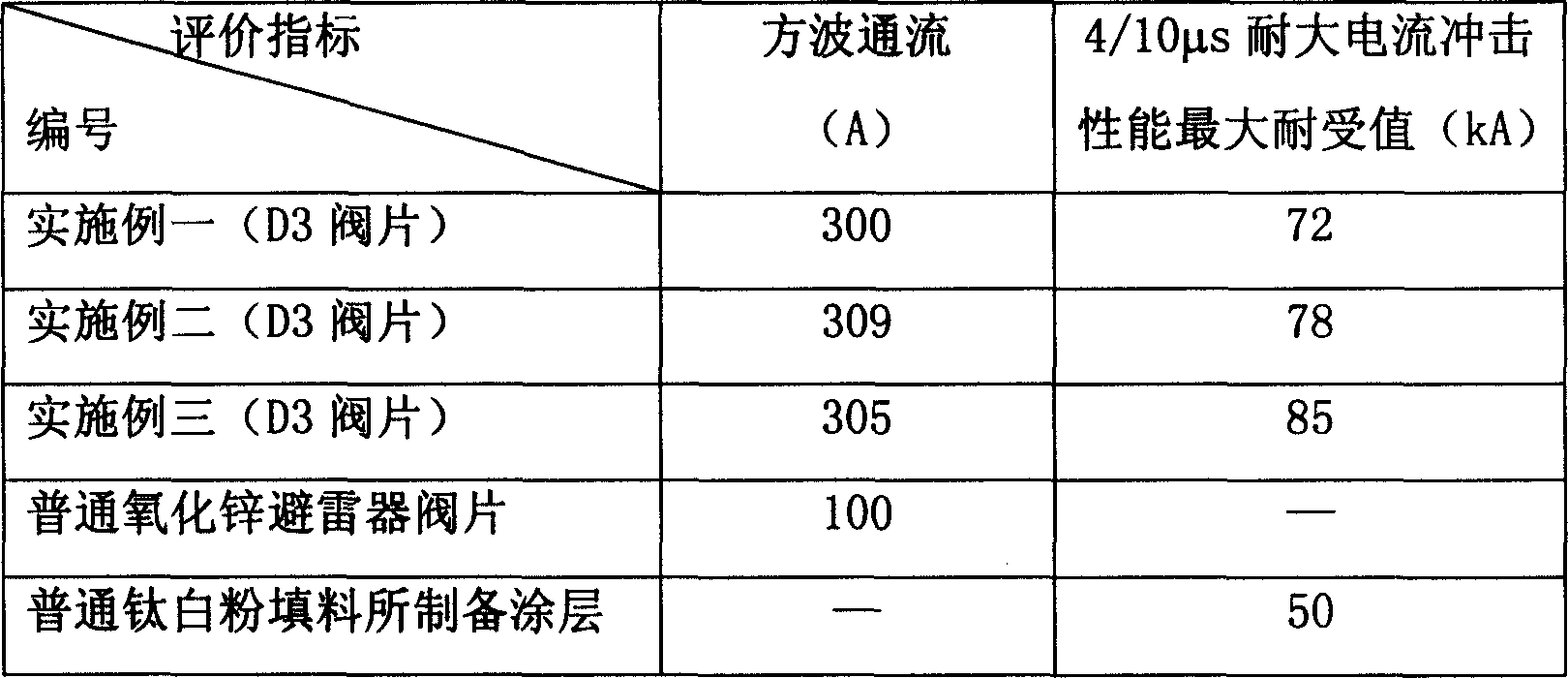

Embodiment 1

[0022] Example 1: Combine 80% (weight percentage) of nano zinc oxide with 20% nano powder additives; 20% of the nano powder additives include nano antimony oxide 10%, nano bismuth oxide 5.6%, nano oxide Silicon 2.4%, nano chromium oxide 1%, nano manganese oxide 1% mixed powder; after the organic lauric acid coating treatment, the material is fully mixed, and then the valve disc is formed by a two-way press and sintered at 1000 ℃ to produce High-pass flow nano zinc oxide valve body. The valve body is sprayed with aluminum and the side is coated with an inorganic high-resistance layer of lead oxide; then the side of the valve is coated with a high-current-resistant nano-insulating composite paint. The high-current resistant nano composite insulating coating is made of nano-level functional coating and epoxy oxazolidone resin; the ratio of the two is 20:80 (weight percentage); the nano-level functional filler treated by organic coating adopts nano For silica, weigh 20% (weight percen...

Embodiment 2

[0023]Example 2: Combine 95% (weight percentage) of nano zinc oxide with 5% nano powder additives; 5% of nano powder additives include nano antimony oxide 2.5%, nano bismuth oxide 0.9%, and nano silicon oxide 0.5%, nano chromium oxide 0.7%, nano manganese oxide 0.4% mixed powder; after the organic lauric acid coating treatment, the material is fully mixed, and then the valve disc is formed by a two-way press, and after sintering at 1100 ℃, a high pass Flow nano zinc oxide valve body. The valve body is sprayed with aluminum and the side is coated with an inorganic high-resistance layer of chromium oxide; then the side of the valve is coated with a high-current-resistant nano-insulating composite coating. The high-current resistant nano composite insulating coating is prepared by nano-level functional coating and epoxy oxazolidone resin; the ratio of the two is 30:70 (weight percentage); the nano-level functional filler treated by organic coating adopts nano For chromium oxide, weig...

Embodiment 3

[0024] Example 3: Combine 85% (weight percentage) of nanometer zinc oxide with 15% of nanometer powder additives; 15% of nanometer powder additives include 8.6% nanometer antimony oxide, 3.4% nanometer bismuth oxide, and nanometer silicon oxide 1.6%, nano-chromium oxide 0.8%, nano-manganese oxide 0.6% mixed powder; after the organic lauric acid coating treatment, the material is fully mixed, and then the valve disc is formed by a two-way press, and after sintering at 1100 ℃, a high pass Flow nano zinc oxide valve body. The valve body is sprayed with aluminum and the side is coated with an inorganic high-resistance layer of chromium oxide; then the side of the valve is coated with a high-current-resistant nano-insulating composite coating. The high-current resistant nano composite insulating coating is prepared by nano-level functional coating and epoxy oxazolidone resin; the ratio of the two is 25:75 (weight percentage); the nano-level functional filler treated by organic coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com