Water polyurethane dye production of coating, textile, artificial leather and leather

A technology of water-based polyurethane and manufacturing method, which is applied in the direction of organic dyes, etc., can solve the problems of poor water resistance and poor color fastness, and achieve the effects of improved water resistance, good friction resistance, and increased color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

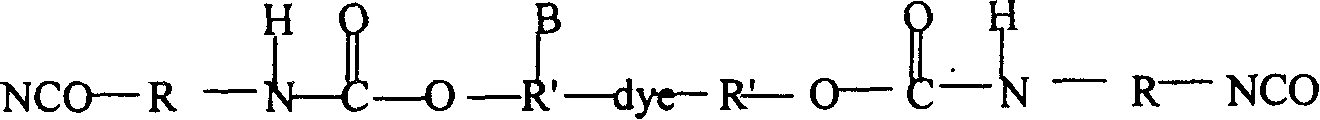

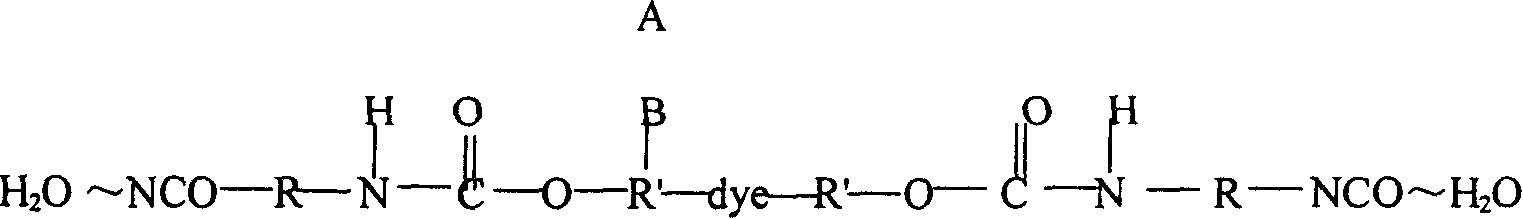

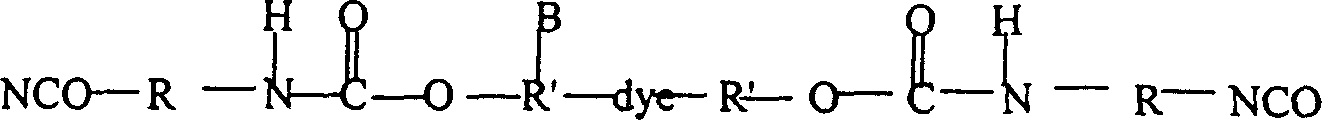

[0044]Mixture of polyether and amino polyether: 50 kg into the reactor, 110 ° C, 0.8 MPa, after dehydration for 0.5 hours, add TDI: 26 kg, 85 ° C for 2-4 hours (NCO% is 11.1%) , add disperse blue: 13.5 kg, diethylene glycol: 3.3 kg, trimethylolpropane: 1.8 kg, N-methylpyrrolidone: 10 kg, react at 80°C for 1-4 hours (NCO% is 4.55 %), add dimethylol propionic acid: 4.8 kilograms, acetone: 60 kilograms, react 1-4 hour (NCO% is 0.67%) under the condition of 60 ℃ to obtain polyurethane dye resin, its structural formula is I, convert polyurethane dye resin to Put into a high-speed disperser, add triethylamine at 800 rpm and 30°C: 4 kg, react for 60 seconds, add water at 30°C: 300 kg, and obtain polyurethane dye emulsion after 60 seconds. Its structural formula is II. Desolvation kettle, 50℃, 0.8MPa to remove acetone to obtain anionic water-based polyurethane dye. The dye has high dyeing fastness, and after wet-process PU leather is soaked in water at 25°C for 72 hours, the color wi...

Embodiment 2

[0051] Polyether polyol: Add 50 kg to the reactor at 110°C, 0.8MPa, after dehydration for 0.5 hours, add TDI: 19 kg, react at 90°C for 2-4 hours (NCO% is 8.24%), add direct green B: 12.8 kg, diethylene glycol: 1.9 kg, trimethylolpropane: 1.6 kg, N-methylpyrrolidone: 10 kg, react at 85°C for 1-4 hours (NCO% is 3.89%), Add N-methyldiethanolamine: 6 kg, acetone: 70 kg, react at 35°C for 1-4 hours (NCO% is 0.46%) to obtain polyurethane dye resin, transfer polyurethane dye resin to high-speed disperser, 800 rpm Add glacial acetic acid at 20°C: 3.4 kg, react for 30 seconds, add 280 kg of water at 20°C, obtain polyurethane dye emulsion after 45 seconds, transfer to the precipitation kettle, remove acetone at 55°C, 0.8MPa to obtain Cationic water-based polyurethane dye. The dye has high dyeing fastness, and the fabric will not fade after being soaked in ethanol for 8 hours.

[0052] In this embodiment, the structural formulas of the polyurethane dye resin and the polyurethane dye em...

Embodiment 3

[0054] 80 kg of polyester polyol, 30 kg of hydroxyl-terminated polybutadiene rubber, 15.8 kg of acid blue BRL, added to the reactor at 110°C and 0.8 MPa, after dehydration for 0.5-2 hours, added TDI: 33 kg, two Methylol propionic acid: 5.8 kg, react at 96°C for 2-4 hours (NCO% is 6.38%), add 1,4-butanediol: 2.2 kg, N-methylpyrrolidone: 15 kg, at 80°C React at low temperature for 1-4 hours (NCO% is 1.49%), add acetone: 100 kg, react at 60°C for 1-4 hours (NCO% is 0.63%) to obtain polyurethane dye resin, and transfer polyurethane dye resin to high-speed disperser , Add triethylamine: 4.8kg at 1400 rpm, 25°C, react for 60 seconds, add water at 25°C: 400 kg, get polyurethane dye emulsion after 60 seconds, transfer to the solvent removal kettle, 50°C, 0.8MPa Remove the acetone to obtain the anionic water-based polyurethane dye. The tensile strength of the dye after film formation: 7.5Mpa, elongation: 450%, good hand feeling, bright emulsion color, especially suitable for dyeing na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com