Solid phase synthesis method by gas stream to increase efficiency and continuous microwave radiation, and apparatus therefor

A technology of solid-phase synthesis and microwave radiation, which is applied in the field of airflow synergistic continuous microwave radiation solid-phase synthesis reaction and equipment, can solve the problems of melting of reactants and products, overheating of high-temperature coking points, temperature out of control, etc., and increase the speed of chemical reactions , reduce energy costs, and speed up the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

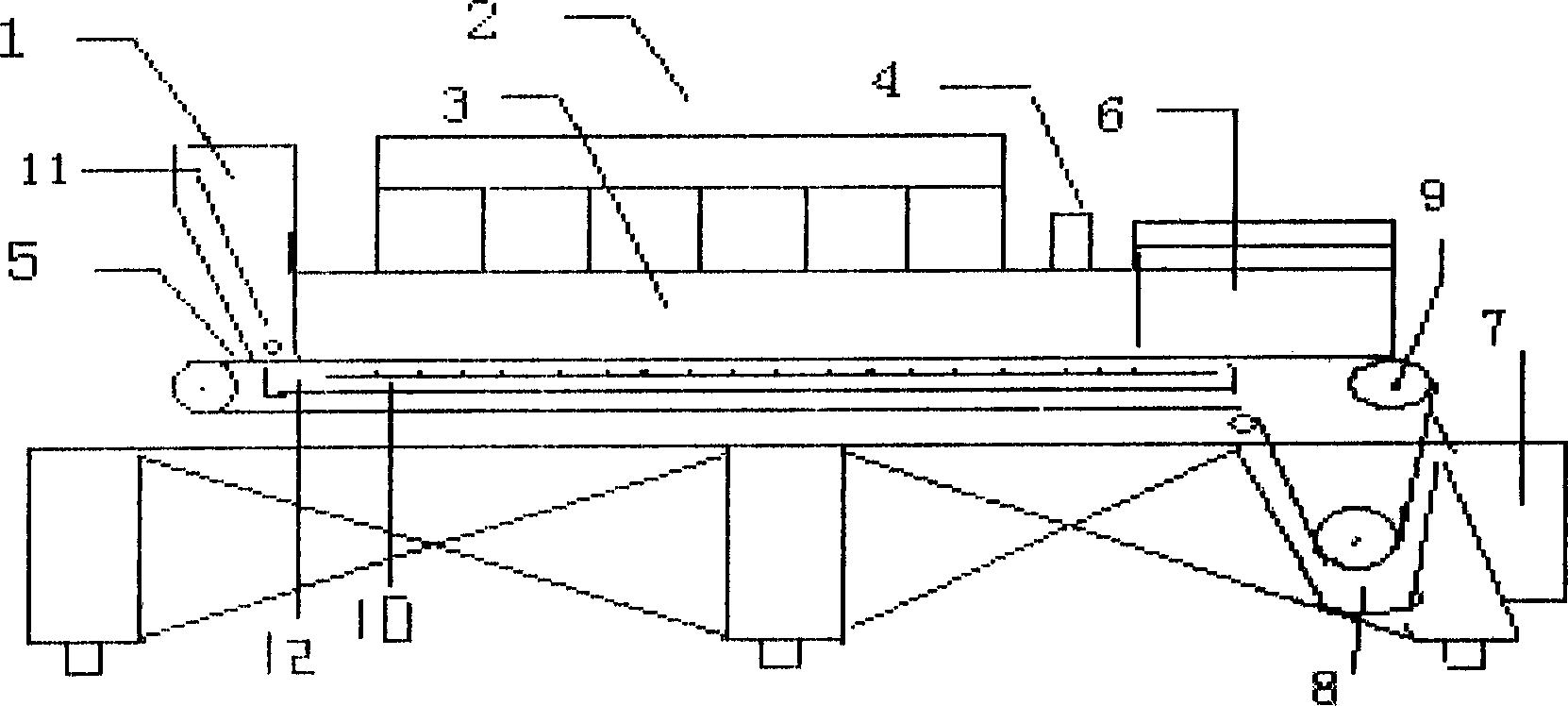

[0016] exist figure 1 Among them, the feeding tank (1), the feeding drum (11) is installed at the bottom of the feeding tank, the feeding tank is connected with the front end of the reaction chamber (3) through the feeding drum, and the microwave source (2) is installed on the upper part of the reaction chamber. A conveyor belt (5) for horizontal mechanical movement is built in the cavity, an output microwave suppressor (6) is installed at the end of the reaction cavity, and an exhaust port (4) is arranged on the upper part of the reaction cavity before the output microwave suppressor. The conveyor belt is composed of non-absorbing microwave, dense microporous, and 200°C-resistant air-permeable mesh belt. The edge of the conveyor belt is closely matched with the air supply groove (12) of the lower trough. The conveyor belt is driven by the driving wheel (9). The conveyor belt passes through the output microwave suppressor and then reacts. Cavity, the product tank (7) is instal...

Embodiment 2

[0017] Embodiment 2. synthetic trace element amino acid chelate (complex)

[0018] 1. Grind methionine and ferrous sulfate to 180 mesh respectively, mix methionine and iron ions evenly at a molar ratio of 1:1 or 1:2, put them into the feeding tank, adjust the thickness of the material to 1cm, and open the gas valve after the conveyor belt spreads the material , turn on the microwave switch, and at the same time, the vacuum pump sucks out the reaction gas, react for 12 minutes, and the conveyor belt transports the reaction product to the product tank, which is the product, and the product chelation rate can reach 91%.

[0019] 2. Glycine and ferrous sulfate are crushed to 180 mesh respectively, glycine and iron ions are uniformly mixed at a molar ratio of 1:1 or 1:2, put into the feeding tank, adjust the thickness of the material to 1cm, and open the gas valve after the conveyor belt spreads the material , turn on the microwave switch, and at the same time, the vacuum pump suck...

Embodiment 3

[0022]Example 3. Synthesis of oligosaccharides

[0023] 1. Add 15% water and a small amount of heteropoly acid to the glucose powder, mix evenly, put it into the feeding tank, adjust the thickness of the material to 1.8cm, after the conveyor belt spreads the material, open the compressed air valve, turn on the microwave switch, and react for 12 minutes , The conveyor belt transports the reaction product to the product trough, cooling and crushing is the product, and the oligosaccharide content can reach 82%.

[0024] 2. Add 10% water and a small amount of heteropoly acid to the sucrose powder, mix evenly, put it into the feeding tank, adjust the thickness of the material to 1.8cm, after the conveyor belt spreads the material, open the gas valve, turn on the microwave switch, and the vacuum pump sucks out the reaction at the same time Gas, react for 12 minutes, the conveyor belt transports the reaction product to the product tank, cools and pulverizes to obtain the product, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com