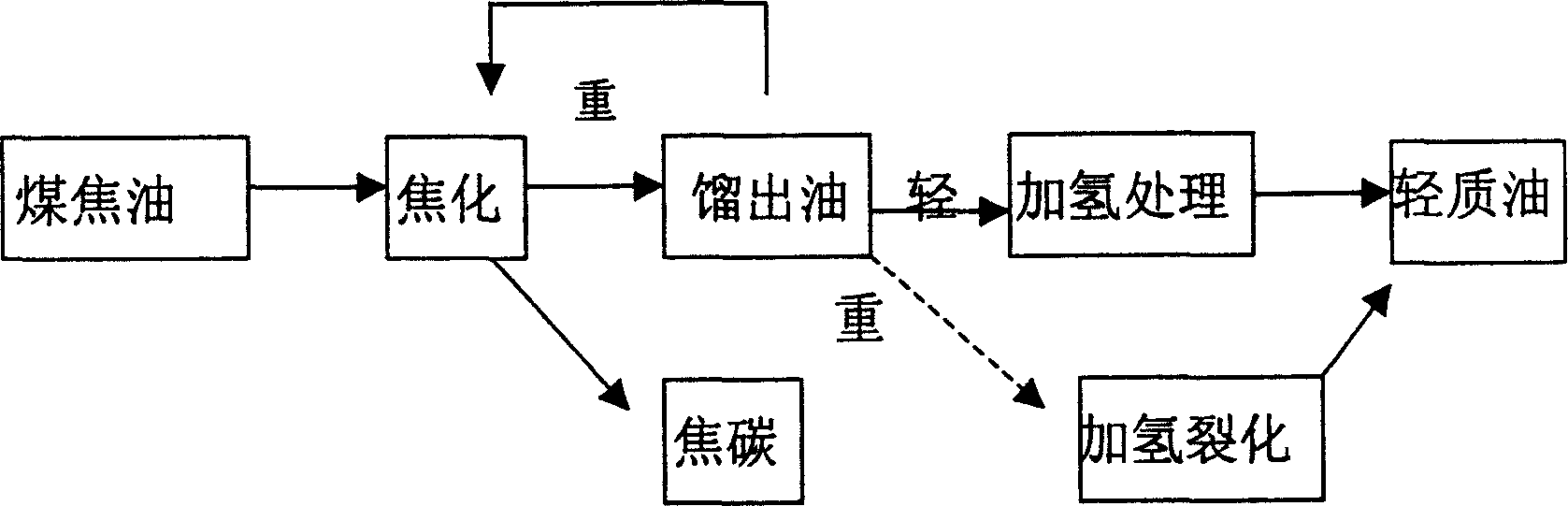

Process for producing fuel oil from coal tar

A technology for fuel oil and coal tar, which is used in tar processing, petroleum industry, hydrotreating technology, etc. Problems such as low yield, to achieve the effect of convenient commercial production and application, moderate operating conditions, and low catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Composition and properties of the coal tar that present embodiment adopts:

[0013] Coal tar is underwater tar, density at 20°C > 1.0g / cm 3 , higher viscosity, kinematic viscosity at 50°C≮200mm 2 / s basically belongs to heavy oil or oil-mixed coal slurry. The residual carbon and ash are also relatively high, respectively ≮5.0% and ≮0.2%, the sulfur content is less than 0.5%, which belongs to low-sulfur coal tar, and the nitrogen and oxygen contents are relatively high, respectively ≮3.4% and ≮4.0%. H / C atomic ratio ≮1.2, higher than ordinary crude oil, belonging to heavy oil. Distillate composition is unstable, coal tar is distilled at true boiling point under atmospheric pressure and reduced pressure, and the distillate of <100°C fraction is very little, and the distillate amount is ≯10% (including moisture ≤4%); the distillate amount of 100~210°C fraction≯ 5%, this fraction belongs to phenol oil; 210℃~230℃ fraction distillate ≯8%, this fraction belongs to naphthale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com