Method for synthesizing nanometer size mordenite

A mordenite, nano-sized technology, applied in mordenite crystalline aluminosilicate zeolite, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problems of expensive raw materials, slow progress, and low concentration of crystallization mother liquor, etc. Achieve the effect of easy industrial production, high crystallinity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

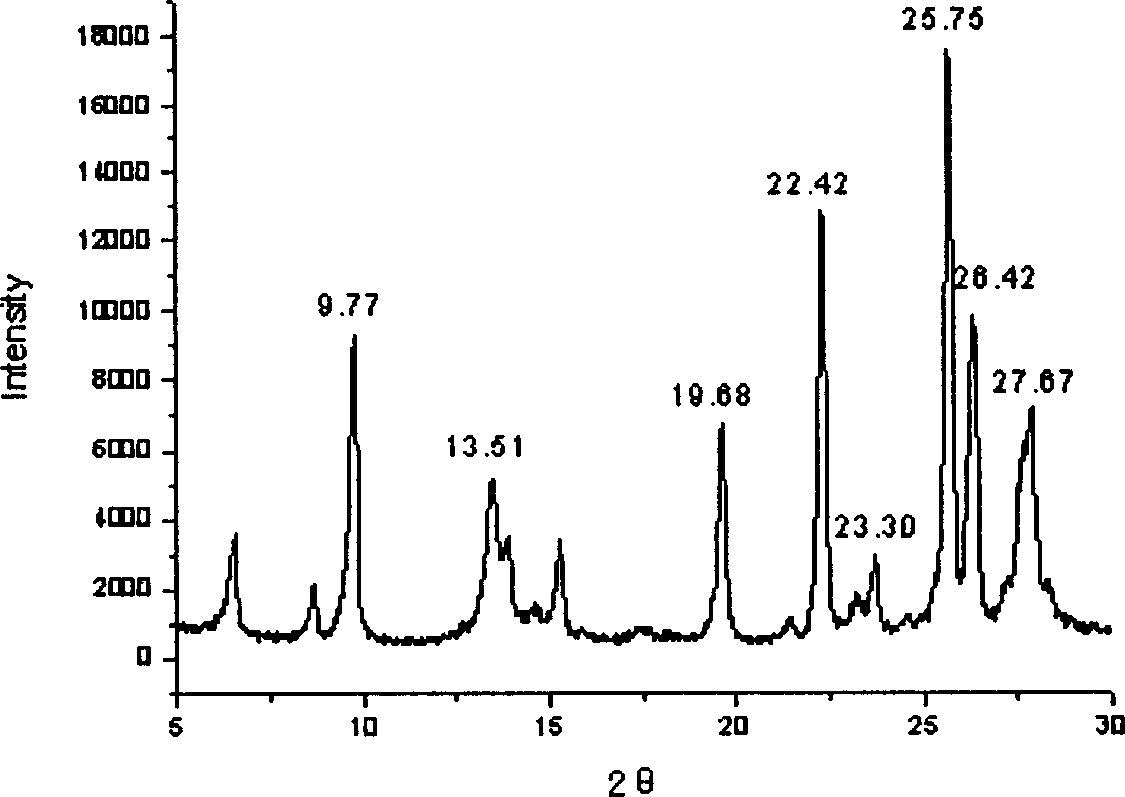

[0038] Synthesize nanometer size mordenite according to the method provided by the invention

[0039] Raw material is

[0040] (A) Silica gel powder: containing SiO 2 92.44 wt%.

[0041] (B) Sodium aluminate: content Al 2 o 3 : 5.301*10 -3 mol / g; Na 2 O: 6.541*10 -3 mol / g, chemically pure.

[0042] (C) Tetraethylammonium bromide: content 61.61wt%, industrial product.

[0043] (D) Sodium chloride: content 99.5wt%, chemically pure.

[0044] (E) Sodium hydroxide: content Na 2 O: 0.0125mol / g, chemically pure.

[0045] (F) propionic acid: content 99.0wt%, chemically pure.

[0046] Take 17.02 grams of sodium aluminate, 12.03 grams of sodium hydroxide, 5.27 grams of sodium chloride, and 91.09 grams of tetraethylammonium bromide solution, dissolve them in 96.49 grams of deionized water while stirring, and dissolve 100 grams of silica gel under constant stirring. Add the powder into the above solution, adjust the pH value to 12.85 with propionic acid, stir evenly, transfer ...

Embodiment 2

[0050] The raw materials are:

[0051] (G) Silica gel powder: containing SiO 2 92.44 wt%.

[0052] (H) Sodium aluminate: content Al 2 o 3 : 5.301*10 -3 mol / g; Na 2 O: 6.541*10 -3 mol / g, chemically pure.

[0053] (1) Tetrapropylammonium bromide: content 61.61wt%, industrial product.

[0054] (J) Sodium chloride: content 99.5wt%, chemically pure.

[0055] (K) Sodium hydroxide: content Na 2 O: 0.0125mol / g, chemically pure.

[0056] (L) Acetic acid: content 99.0wt%, chemically pure.

[0057] 12.82 grams of sodium aluminate, 9.06 grams of sodium hydroxide, 5.96 grams of sodium chloride, and 116.1 grams of tetrapropylammonium bromide solution were dissolved in 216.01 grams of deionized water under stirring, and 75 grams of silica gel powder were dissolved under constant stirring. Add it into the above solution, adjust the pH value to 12 with formic acid, stir evenly, transfer it to a stainless steel pressure kettle, stir and age at room temperature for 9 hours, and carry ...

Embodiment 3

[0060] Raw material is

[0061] (M) Silica gel powder: containing SiO 2 92.44 wt%.

[0062] (N) Sodium aluminate: content Al 2 o 3 : 5.301*10 -3 mol / g; Na 2 O: 6.541*10 -3 mol / g, chemically pure.

[0063] (O) Tetraethylammonium hydroxide: content 61.61wt%, industrial product.

[0064] (P) Sodium chloride: content 99.5wt%, chemically pure.

[0065] (Q) Sodium hydroxide: content Na 2 O: 0.0125mol / g, chemically pure.

[0066] (R) Acetic acid: content 99.0wt%, chemically pure.

[0067] Take 8.55 grams of sodium aluminate, 6.04 grams of sodium hydroxide, 7.94 grams of sodium chloride, and 46.03 grams of tetraethylammonium hydroxide solution, dissolve them in 92.86 grams of deionized water while stirring, and dissolve 50 grams of silica gel under constant stirring. Add the powder to the above solution, adjust the pH value to 8.15 with acetic acid, stir evenly, transfer to a stainless steel pressure kettle, stir and age at room temperature for 13 hours, and crystallize acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com