Infiltration liquid treatment method in domestic refuse burying field

A technology of municipal solid waste and treatment method, applied in the field of leachate treatment of municipal solid waste landfills, can solve the problems of high retention rate, high cost and high concentration, and achieve the effects of no secondary pollution, reliable operation and advanced technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

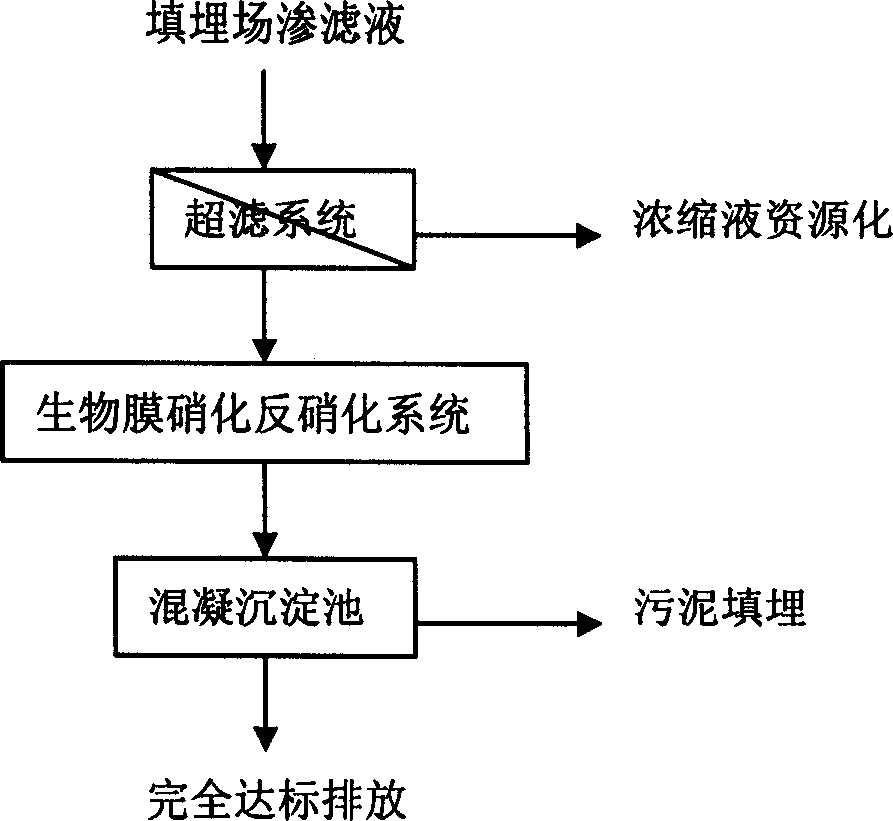

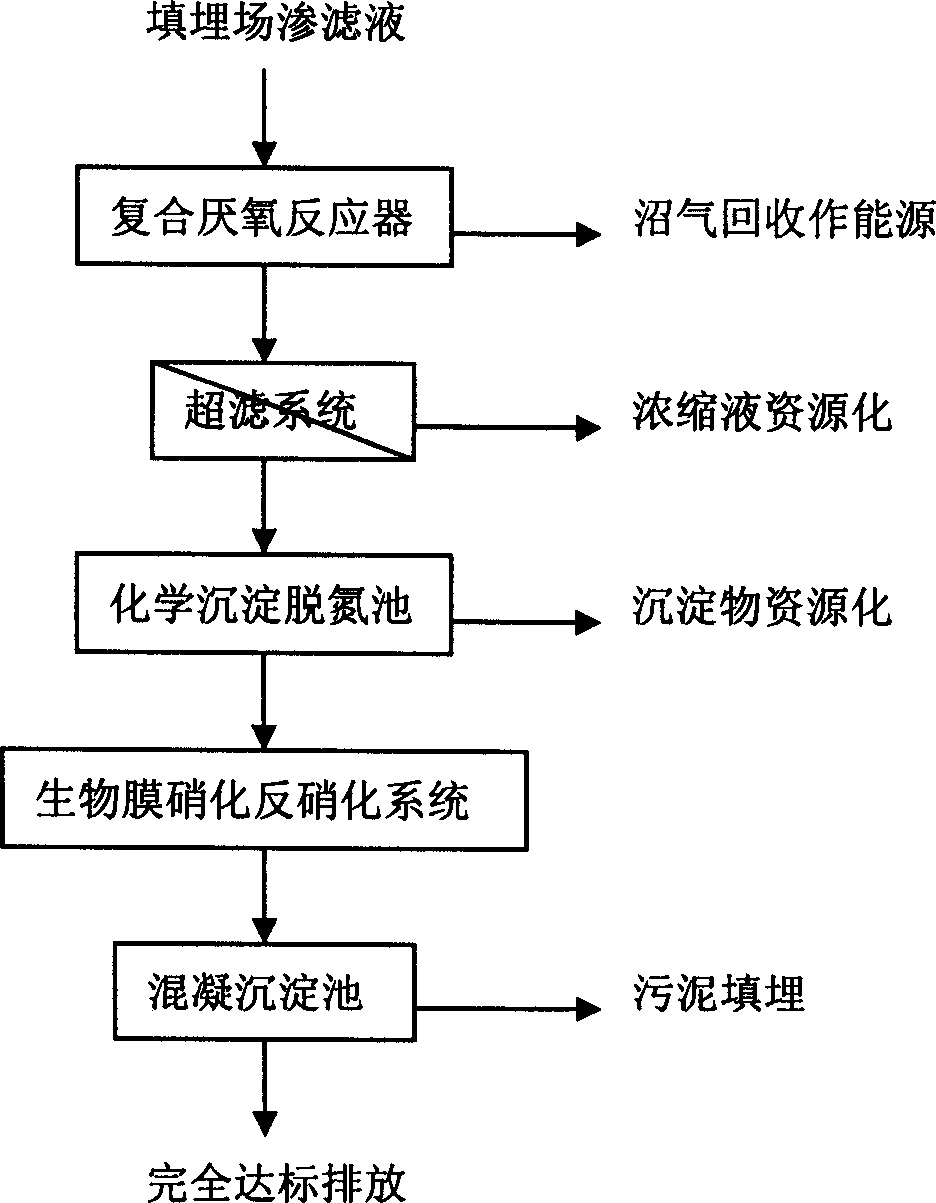

[0017] Combine figure 1 Take the treatment of leachate from a sanitary landfill of municipal solid waste in Beijing as an example to illustrate the present invention.

[0018] The sanitary landfill started operation in 1997 and has now entered the stage of methane production. It produces 200 tons of leachate per day. The water quality is as follows: pH 7.67~8.48, COD cr 2220~3520mg / L, BOD 5 230~617mg / L, TOC 841~1590mg / L, NH 4 -N is 748~1460mg / L, the conductivity is 18.2~24.1ms / cm, the concentration of heavy metals is lower than the first level emission standard, and the color is yellow to reddish brown. It can be seen that the leachate has been fully anaerobic decomposed in the landfill, and the ammonia nitrogen concentration is less than 1500mg / L. Pump the leachate into a sand filter tank and a small microfiltration device to remove particles such as sludge with a particle size greater than 1-10μm. The effluent is then pumped into the ultrafiltration system. The relative molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com