Preparation and use of injectable isopropyl acrylamide tripolymer as thrombus material and its use

A technology of isopropylacrylamide terpolymer and n-propylacrylamide, which is applied in the field of vascular embolization materials and can solve the problems of unfavorable injection and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

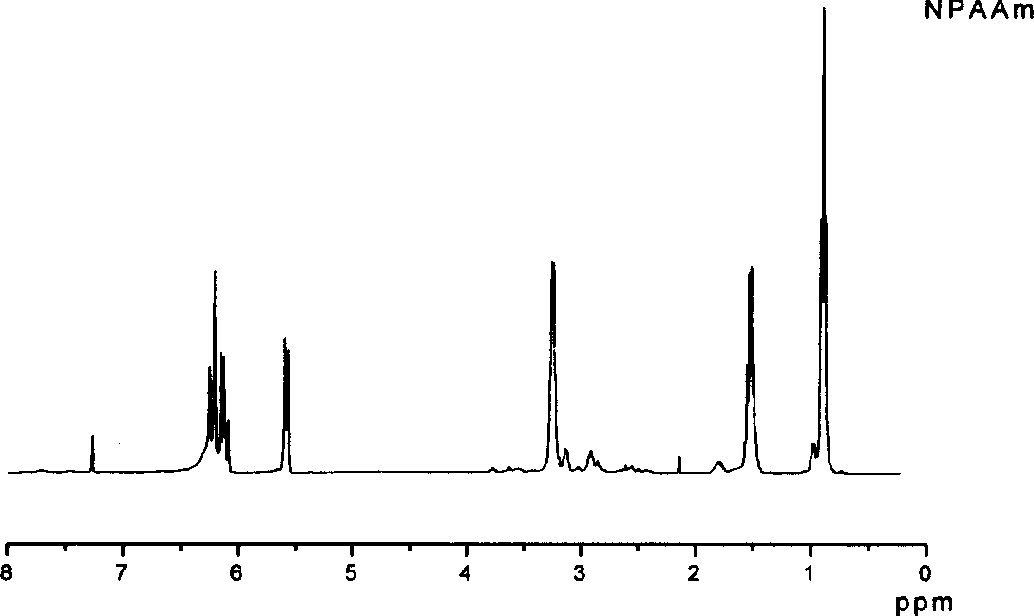

[0026] 65.86 ml of n-propylamine after water removal was dissolved in 160 ml of tetrahydrofuran, and 32.47 ml of acryloyl chloride was added dropwise under magnetic stirring in an ice-water bath. After the reaction is complete, remove the generated amine salt by vacuum filtration, and remove tetrahydrofuran by rotary evaporation to obtain liquid n-propylacrylamide (NPAAm).

[0027] Dissolve 1.8106g of isopropylacrylamide, 1.8106g of n-propylacrylamide and 0.1065ml of vinylpyrrolidone in 80ml of deionized water; pass nitrogen gas for 30min under magnetic stirring, add 0.0268g of potassium persulfate and 0.0149g of tetramethylethylenediamine ml; the temperature was controlled in a water bath at 20°C, and the reaction was carried out under nitrogen protection for 8 hours. After the reaction, the mixed solution was put into a dialysis bag for purification (molecular weight cut-off 5000), and the water was changed every 12 hours. After 5 days of dialysis, freeze-dried to obtain PNI...

Embodiment 2

[0035] The synthesis of monomer n-propylacrylamide is the same as in Example 1.

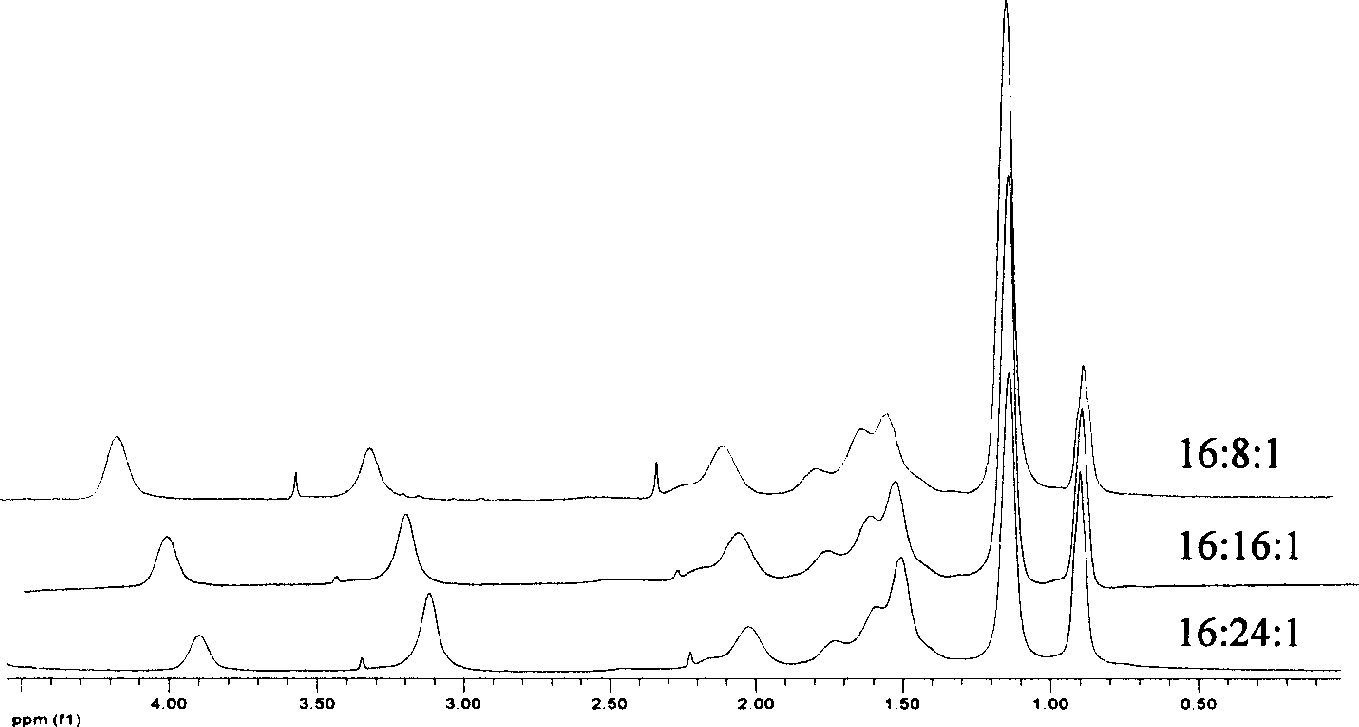

[0036] Dissolve 0.9053g of isopropylacrylamide, 1.3579g of n-propylacrylamide and 0.0532ml of vinylpyrrolidone in 46ml of deionized water; pass nitrogen gas for 30min under magnetic stirring, add potassium persulfate 0.0166g and tetramethylethylenediamine 0.0092 ml; the temperature was controlled in a water bath at 20°C, and the reaction was carried out under nitrogen protection for 8 hours. After the reaction, the mixed solution was put into a dialysis bag for purification (molecular weight cut-off 5000), and the water was changed every 12 hours. After 5 days of dialysis, freeze-dried to obtain PNINAVP of 16:24:1.

[0037] Proton NMR spectrum detection: an appropriate amount of sample is dissolved in deuterated water (D 2 O) in, record on NMR spectrometer Varian UNITY plus 400 1 H-NMR spectrum, such as figure 2 shown.

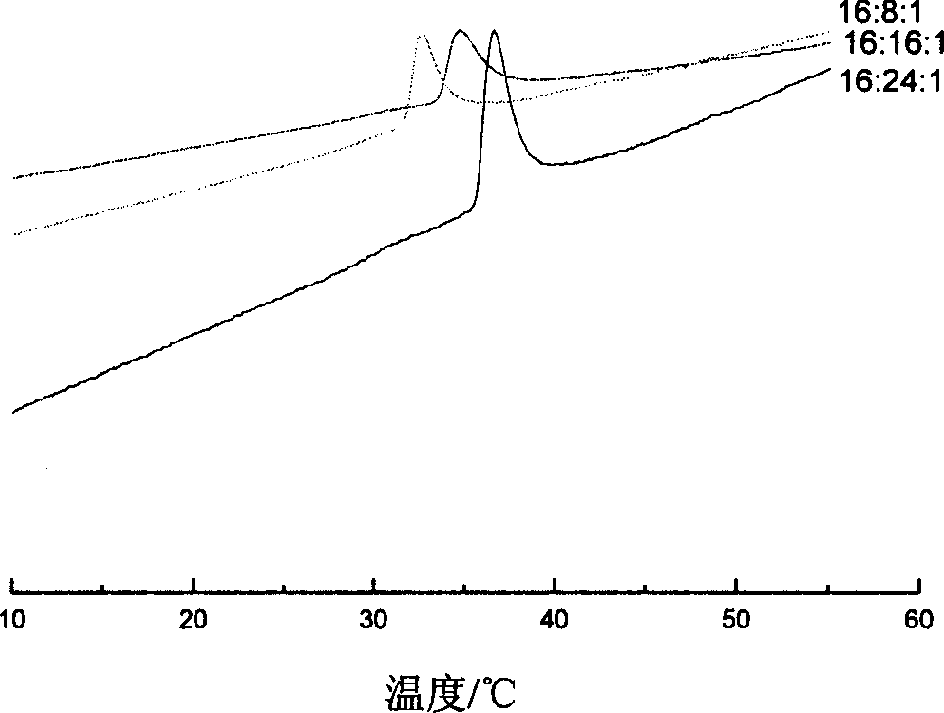

[0038] DSC detection: Weigh a certain amount of copolymer to prepare a ...

Embodiment 3

[0044] The synthesis of monomer n-propylacrylamide is the same as in Example 1.

[0045] Dissolve 0.9053g of isopropylacrylamide, 0.4526g of n-propylacrylamide and 0.0532ml of vinylpyrrolidone in 28ml of deionized water; pass nitrogen gas for 30min under magnetic stirring, add potassium persulfate 0.0101g and tetramethylethylenediamine 0.0056 ml; the temperature was controlled in a water bath at 20°C, and the reaction was carried out under nitrogen protection for 8 hours. After the reaction, the mixed solution was put into a dialysis bag for purification (molecular weight cut-off 5000), and the water was changed every 12 hours. After 5 days of dialysis, freeze-dried to obtain PNINAVP of 16:8:1.

[0046] Proton NMR spectrum detection: an appropriate amount of sample is dissolved in deuterated water (D 2 O) in, record on NMR spectrometer Varian UNITY plus 400 1 H-NMR spectrum, such as figure 2 shown.

[0047] DSC detection: Weigh a certain amount of copolymer to prepare a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com