Microbial fodder additive and its preparing method and use

A technology of microbial feed and additives, applied in animal feed, animal feed, application, etc., can solve the problems of unstable efficacy, short survival time of viable cells, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

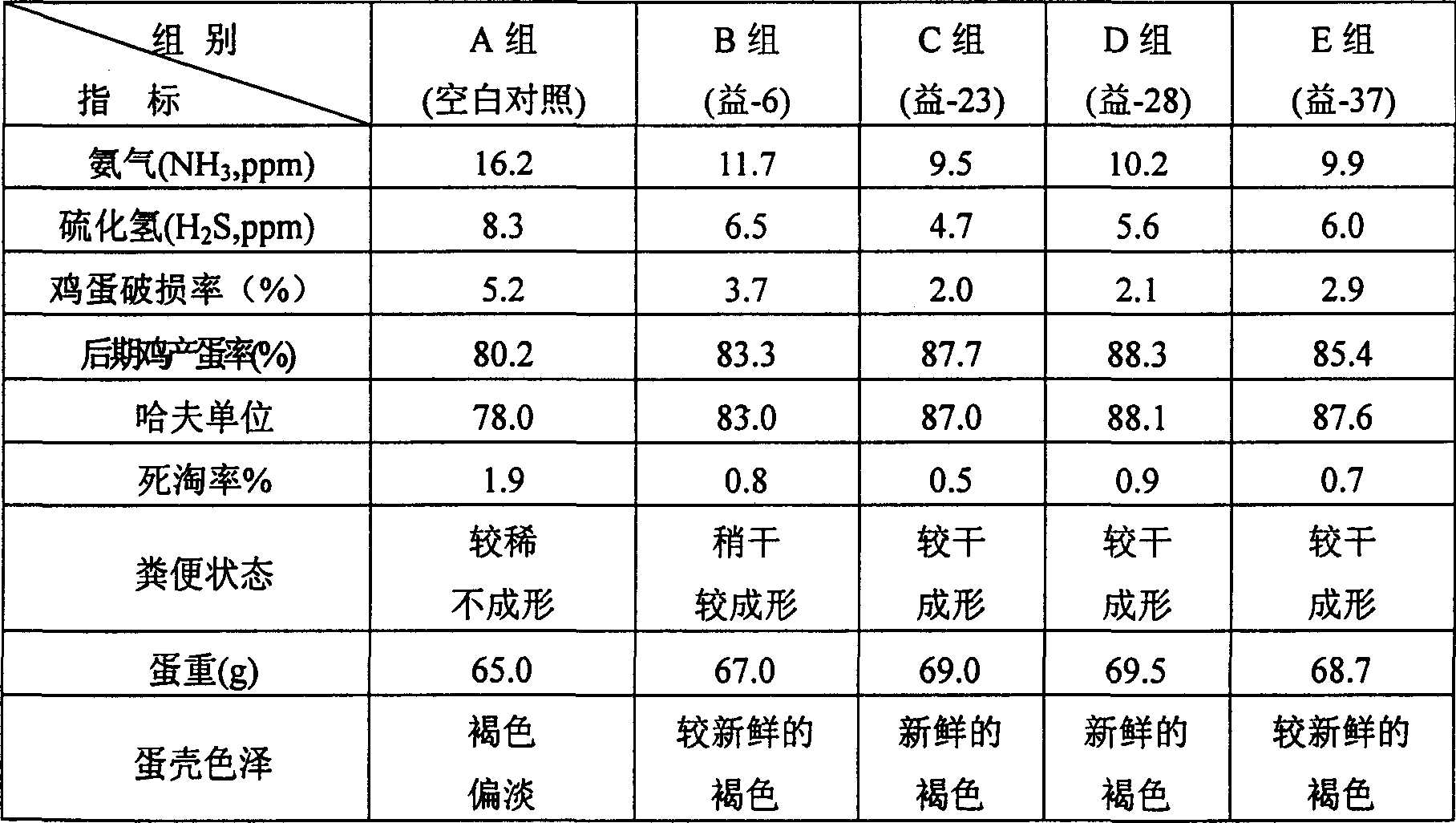

Image

Examples

Embodiment 1

[0087] Example 1. Fermentation broth for culturing Bacillus subtilis (A)

[0088] 1) Plate culture and rejuvenation: The preserved strains of Bacillus subtilis are streaked on the Bacillus plate medium by streaking inoculation, and cultured at 30°C for 18 hours to rejuvenate Bacillus subtilis and form a single colony; The Bacillus subtilis culture medium is a mixture prepared in the following ratio: peptone 0.5% (W / V, the same below), glucose 0.5%, beef extract 0.5%, potassium dihydrogen phosphate 0.3%, agar 3%, pH= 7.5~7.6, sterilize at 121℃ for 30 minutes, spare;

[0089]2) Making seeds of shake flasks (triangular flasks): select a typical single colony from the Bacillus subtilis colonies cultured in step 1), inoculate it into Bacillus liquid culture medium, and cultivate at 32°C for 30 hours to obtain Bacillus subtilis shake flasks Seed liquid; the bacillus liquid medium is a mixed liquid prepared in the following proportions: peptone 0.5%, glucose 2%, beef extract 0.5%, potass...

Embodiment 2

[0092] Example 2. Fermentation broth for culturing Bacillus subtilis (A)

[0093] 1) Plate culture and rejuvenation: The preserved strains of Bacillus subtilis are streaked on the Bacillus plate medium by streaking inoculation, and cultured at 30°C for 18 hours to rejuvenate Bacillus subtilis and form a single colony; The Bacillus subtilis culture medium is a mixture prepared in the following proportions: peptone 0.5% (% refers to weight and volume percentage, the same below), glucose 0.5%, beef extract 0.5%, potassium dihydrogen phosphate 0.3%, agar 3%, pH=7.5~7.6, sterilize at 121°C for 30 minutes, ready for use;

[0094] 2) Making the seeds of the shake flask (triangle flask): select a typical single colony from the Bacillus subtilis colonies cultivated in step 1), inoculate it into the Bacillus liquid medium, and cultivate it at 32°C for 30 hours to obtain the Bacillus subtilis shake flask Seed liquid; the bacillus liquid medium is a mixed liquid prepared in the following prop...

Embodiment 3

[0098] Example 3. Fermentation broth (B) for culturing Bacillus cereus

[0099] The type of microorganism is Bacillus cereus. The culture medium, conditions, and preparation methods are the same as those in Example 1. The fermentation broth of Bacillus cereus is obtained. Finally, according to the medium and culture conditions used for plate culture and rejuvenation of Bacillus cereus, The content of viable bacteria in the fermentation broth of Bacillus cereus is tested by conventional plate counting. According to the count results, the viable bacteria content is diluted to 10 with sterilized tap water 8 CFU / ml, 10 9 CFU / ml and 10 10 CFU / ml, to obtain the standby liquid (B) of the fermentation broth of Bacillus cereus, to be post-processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com