Hollow fiber alloy nano filtering membrane of cellulose triacetate and its production method

A technology of cellulose triacetate and its manufacturing method, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of poor biocompatibility, strong pH sensitivity, complex separation system, etc., and achieve good resistance Function, large specific surface area, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

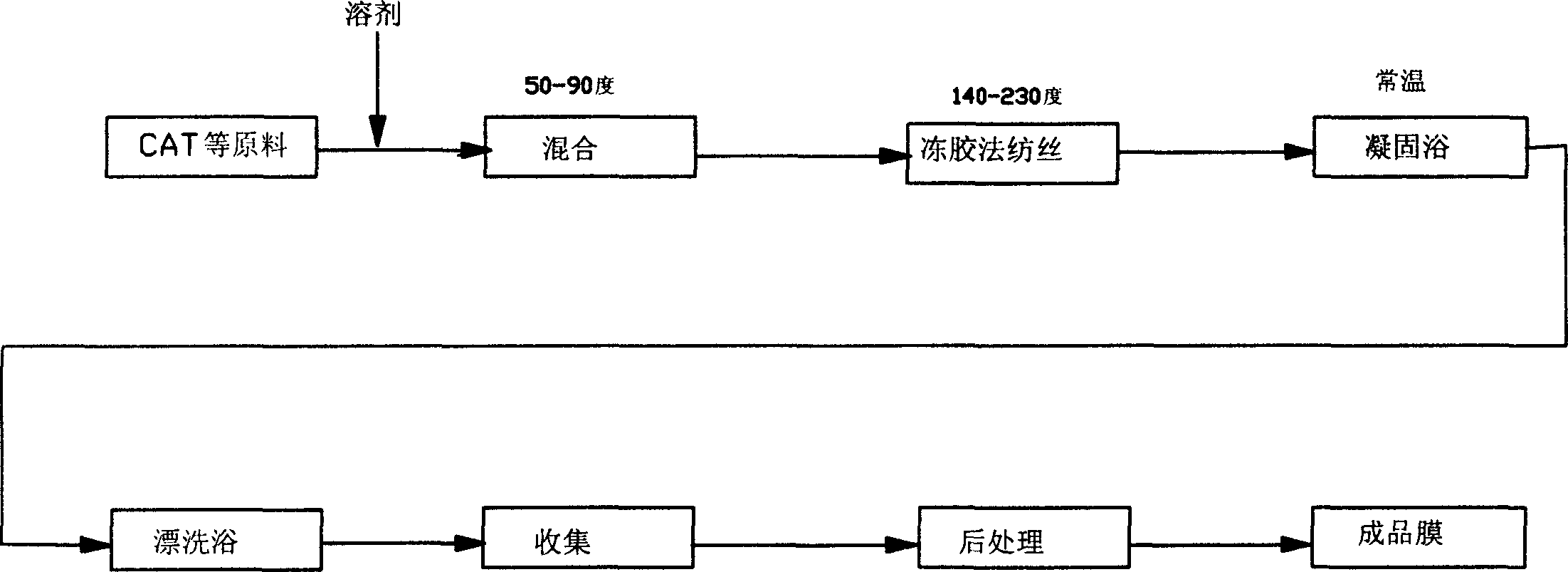

Method used

Image

Examples

Embodiment 1-2

[0031] With triacetate cellulose as the matrix phase, polyethersulfone, polyacrylonitrile and polyvinylidene fluoride as the dispersed phase, according to the weight ratio of triacetate cellulose hollow fiber alloy nanofiltration membrane, use 45% triacetate cellulose, 25% Dispersion components (polyethersulfone, polyacrylonitrile, polyvinylidene fluoride), 30% porogen (polyethylene glycol, triethyl phosphate) are dissolved in a mixed solvent of sulfolane and N-methylpyrrolidone. Stir and mix evenly, swell and mature at a constant temperature of 85°C for 24 hours, and granulate to make a spinning material for use. The spinning material is processed by the jelly spinning process and at a suitable temperature, and is pressed into the hollow fiber spinneret with two concentric circles by the gear metering pump through the screw extruder, and the hollow fiber is extruded from the outer circle of the spinneret. Silk liquid, the inner circular hole is filled with nitrogen, the nasce...

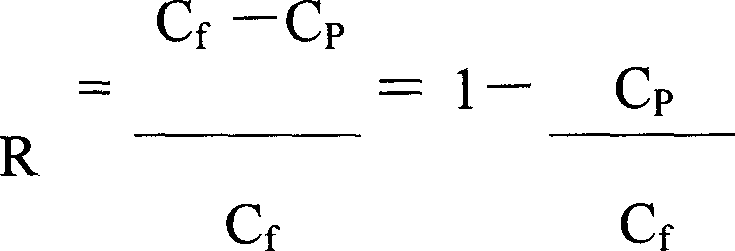

Embodiment 3-4

[0036] As in previous examples, according to the above-mentioned manufacturing method, the weight ratio of cellulose triacetate hollow fiber alloy membrane is 85% cellulose triacetate, 5% dispersed components (polyvinylidene fluoride, polymethyl methacrylate), 10 % porogen (polyethylene glycol, glycerin) to prepare triacetate cellulose hollow fiber alloy nanofiltration membrane. The prepared alloy nanofiltration membrane was tested for its removal performance under the conditions of 2000mg / L magnesium sulfate aqueous solution, operating pressure of 1.2MPa, and operating temperature of 25°C.

[0037] Example Dispersed component Water flux, (L / m 2 h) Removal rate, (%)

[0038] 3 polyvinylidene fluoride 27.5 85.3

[0039] 4 Polymethyl methacrylate 25.1 66.4

Embodiment 5-6

[0041] As the manufacturing method of the cellulose triacetate hollow fiber alloy nanofiltration membrane of the previous embodiment 1-2, with 75% cellulose triacetate, 5% dispersion component (polyacrylonitrile, polyether sulfone) 20% porogen ( 1,2-propanediol, triethyl phosphate) to prepare cellulose triacetate hollow fiber alloy nanofiltration membrane. The prepared alloy nanofiltration membrane was tested for its removal performance under the conditions of 2000mg / L magnesium sulfate aqueous solution, operating pressure of 1.2MPa, and operating temperature of 25°C.

[0042] Example Dispersed component Water flux, (L / m 2 h) Removal rate, (%)

[0043] 5 polyacrylonitrile 31.4 75.3

[0044] 6 Polyethersulfone 28.1 73.1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com