Piston ring and thermal sprayed coating for use therein, and method for manufacture thereof

A manufacturing method and spray coating technology, applied in the field of piston rings, can solve the problems of height difference, wear of piston rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] (1) Manufacture of test piece

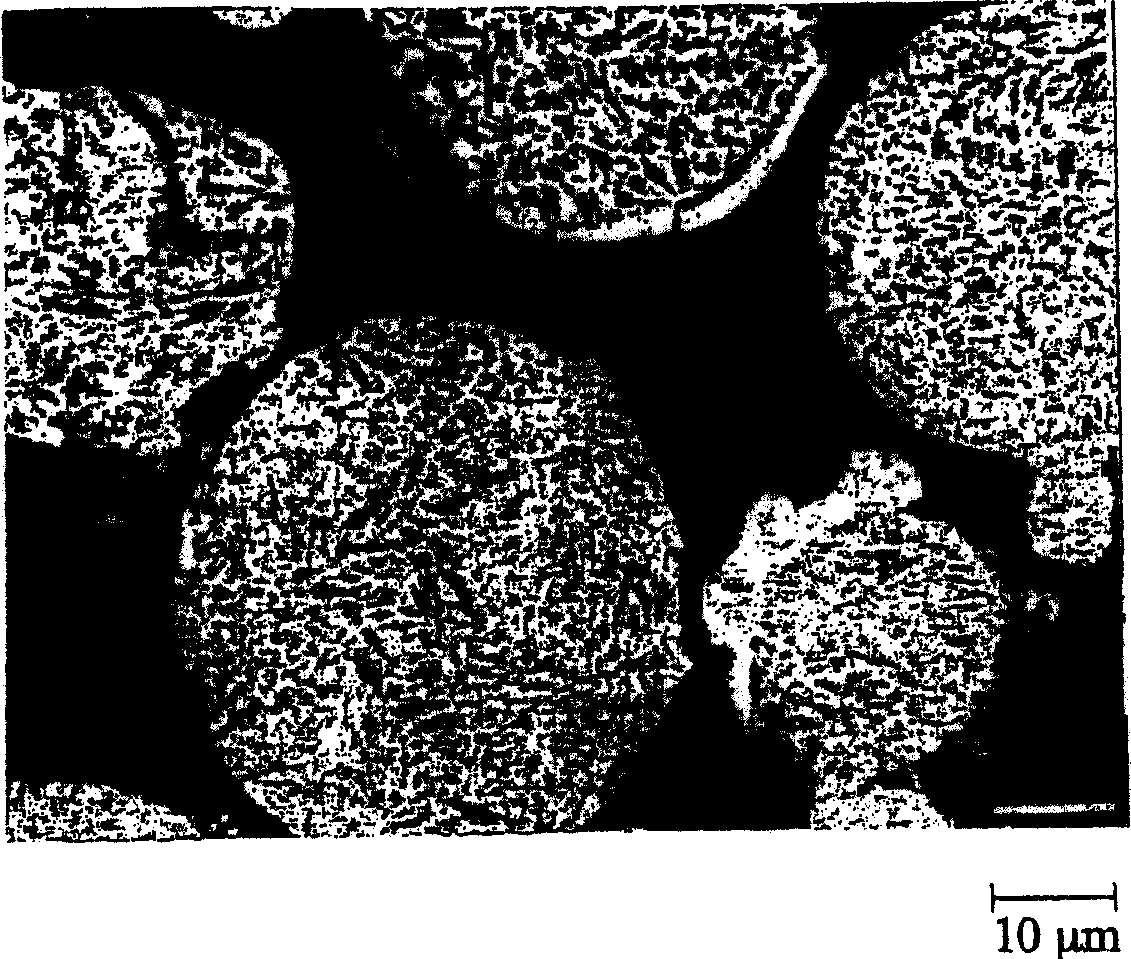

[0083] Manufacture a prism with a length of 5mm, a width of 5mm, and a length of 20mm made of the same spherical graphite cast iron (FCD600) as the base material of the piston ring, and grind one end surface (5mm×5mm) into a curved surface with a radius of curvature R of 10mm . On this curved surface, using #30 alumina particles, plasma treatment was performed to make the surface roughness (10-point average roughness Rz) 20 μm, and a test piece base material was produced. The spraying powder used was rapid solidification fine particles ("Sulzer Metco 5241", manufactured by Sulzer Metco). Sulzer Metco5241 is a spraying powder that melts a raw material having a composition of Cr:Ni:C=54:39:7 (mass%) and micronizes it by rapid solidification. Cr and C generate chromium carbide by melting and rapid solidification , Ni and Cr generate Ni-Cr alloy. That is, Sulzer Metco 5241 has a structure in which precipitated chromium carbide particles ar...

Embodiment 2

[0103] As the spraying powder, except using CRC-410 (mass ratio of chromium carbide particles: Ni-Cr alloy = 70: 30) manufactured by Praxair manufactured by the rapid solidification particle method, the same method as in Example 1 was used to produce a powder equivalent to Piston ring test piece. The surface roughness (10-point average roughness Rz) of the sprayed coating subjected to finishing processing was 2.64 μm.

[0104] The area ratio of the pores in the sprayed coating was 5% (therefore, the porosity was 5% by volume), and the average pore diameter of the pores was 3 μm. The area ratio of chromium carbide particles in the sprayed coating except for pores was 63%, and the average pore diameter of chromium carbide was 2.8 μm. As in Example 1, it has a characteristic shape in a dendritic or non-equiaxed coagulated tissue. As in Example 1, the average hardness of the measured spray coating was 815Hv0.1, and the standard deviation of hardness was 142Hv0.1.

[0105] As a ...

Embodiment 3

[0107] Add 15 parts by mass of polyvinyl alcohol as a binder, after spray drying and granulation, classification, sintering at 800°C, manufacturing Figure 8 Granulated sintered powder of chromium carbide particles / Ni-Cr alloy powder shown. The particle size of the granulated sintered powder is below 325 meshes.

[0108] After the plasma treatment was performed on the curved surface of the prism made of spherical graphite cast iron (FCD600) as in Example 1, activation treatment was performed just before thermal spraying in the same manner as in Example 1. Use the HVAF spraying gun (manufactured by Intelli-Jet Co., Ltd.) to carry out high-speed flame spraying on the curved surface of the prism with the above-mentioned granulated sintering powder under the conditions of flame velocity 2100m / sec and particle velocity 800m / sec, to form a thickness of 300μm. coating. As in Example 1, after finishing, the surface roughness (10-point average roughness Rz) of the thermal sprayed co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com