Fungus and method for preparing vanillin from isoeugenol converted by microorgan

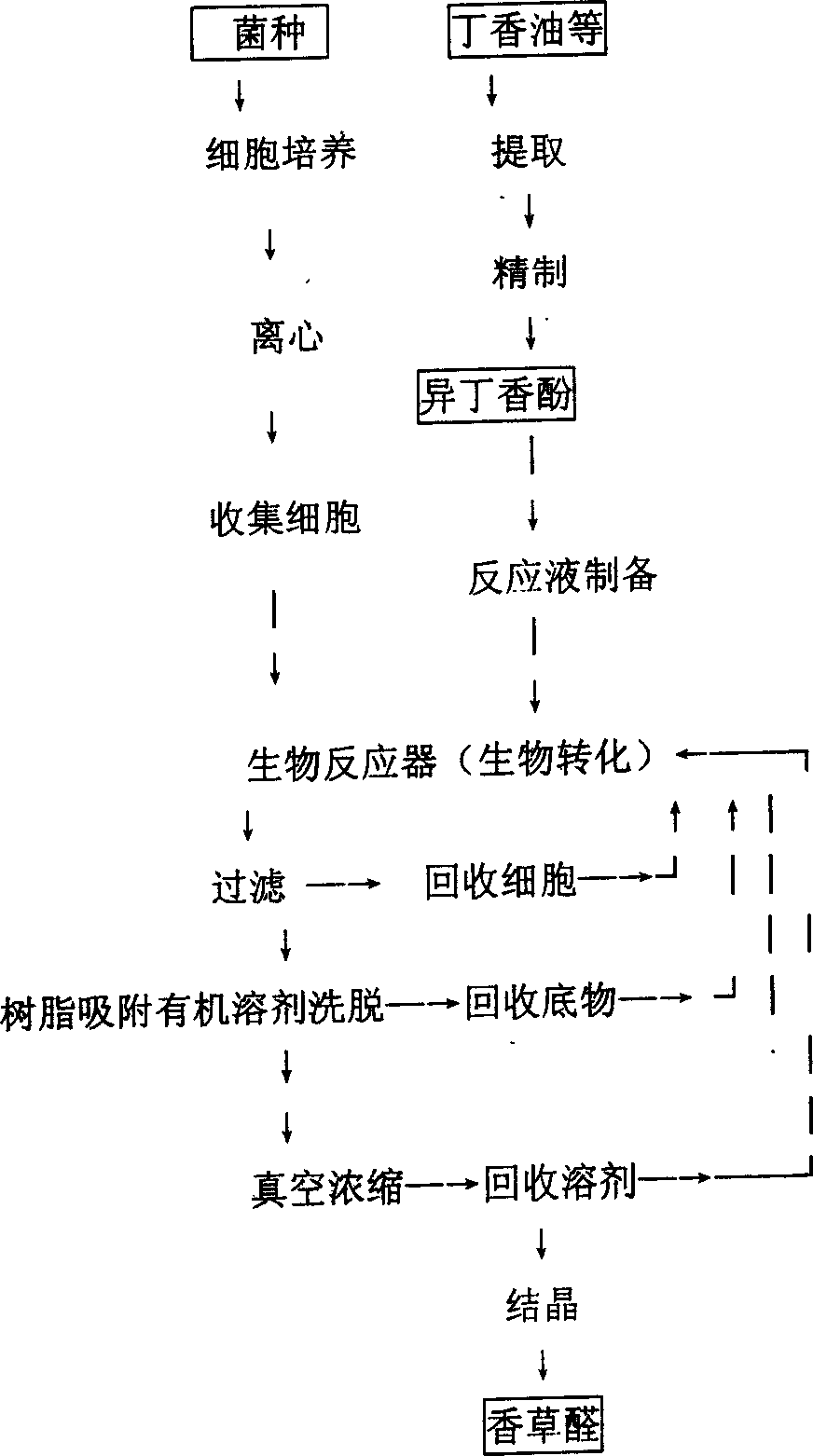

A technology of microbial strains and isoeugenol, which is applied in the direction of bacteria, can solve the problems of low product concentration and conversion rate, and achieve the effects of high substrate total molar conversion rate, high purity, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The soil samples contaminated by different spices were collected from a spices Co., Ltd. in Wuxi. Weighed about 10 g of each soil sample, suspended in 0.9% NaCl solution, filtered with 8 layers of gauze to remove larger impurity particles, and inoculated To enrich medium (0.2% isoeugenol; 0.5% glucose; 0.5% yeast extract; 0.5% peptone; K 2 HPO 4 ·3H 2 O 1.4%; KH 2 PO 4 0.5%; MgSO 4 ·7H 2 O 0.2%; pH 7.0), after culturing for 24 hours, continuously transfer the selection medium (without glucose, other enrichment medium) for 4 times, and spread the selective plate (the components are the same as the selection medium, containing 2% agar ). After preliminary screening, a total of 14 strains of bacteria were isolated and could grow on a plate with isoeugenol as the sole carbon source. They were all Bacillus by microscopic examination. They were transferred to the reaction solution for transformation for 3 days, and vanilla was identified by TLC. Aldehydes, found that ...

Embodiment 2

[0053] The physiological and biochemical characteristics of the screened SW-B9 strain were identified according to the eighth edition of Bergey's manual, and the results are shown in Table 3. The 16S rDNA identification was carried out according to the method of the refined molecular biology experiment guide, and the results are shown in Table 4. According to the experimental results, it can be confirmed that it belongs to Bacillus fusiformis, and it is proposed to be named Bacillus fusiformis SW-B9 (CGMCC1347).

[0054] Physiological and biochemical characteristics

[0055] +, more than 90% positive; -, more than 90% negative; D, 11%-89% positive.

[0056] 1 GACGAACGCT GGCGGCGTGC CTAATACATG CAAGTCGAGC GAACAGAGAA GGAGCTTGCT

[0057] Among them, the composition is A 25%; C 23%; G 31%; T 21%.

Embodiment 3

[0059] Carry out cultivation and fermentation with Bacillus fusiformis CGMCC1347 (SW-B9) bacterial strain, the slant medium is conventional LB medium, and seed medium is composed of: glucose 0.3%; corn steep liquor 5.5%; urea 0.3%; K 2 HPO 4 ·3H 2 O 0.09%; KH 2 PO 4 0.03%, MgSO 4 ·7H 2 O 0.1%; pH 7.0; use 250mL Erlenmeyer flask to fill 25mL culture medium, and culture at 37°C and 180r / min shaker for 12 hours as seed culture solution. The composition of the fermentation medium is: corn steep liquor 5.5%; K 2 HPO 4 ·3H 2 O 0.2%; Urea 0.1%; MgSO 4 ·7H 2 O0.1%; pH 7.5; put 50mL medium in a 250mL Erlenmeyer flask, culture at 37°C for 12 hours on a shaker at 180r / min, then add 1mmol / L vanillin as an inducer to continue culturing for 8 hours, and finally obtain stem cells containing Fermentation broth weighing 6.9 g / L.

[0060]Centrifuge the fermentation broth at 3000r / min for 10min to obtain 0.36g of wet bacteria, put 0.4mL of isoeugenol in a 250mL Erlenmeyer flask, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com