Method of inhibiting water content variation of composition and use thereof

A composition and inhibitor technology, applied in soap detergent composition, surface active non-soap compound and detergent composition, detergent compounding agent, etc., can solve the problem of high cost, achieve the effect of inhibiting modification and maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

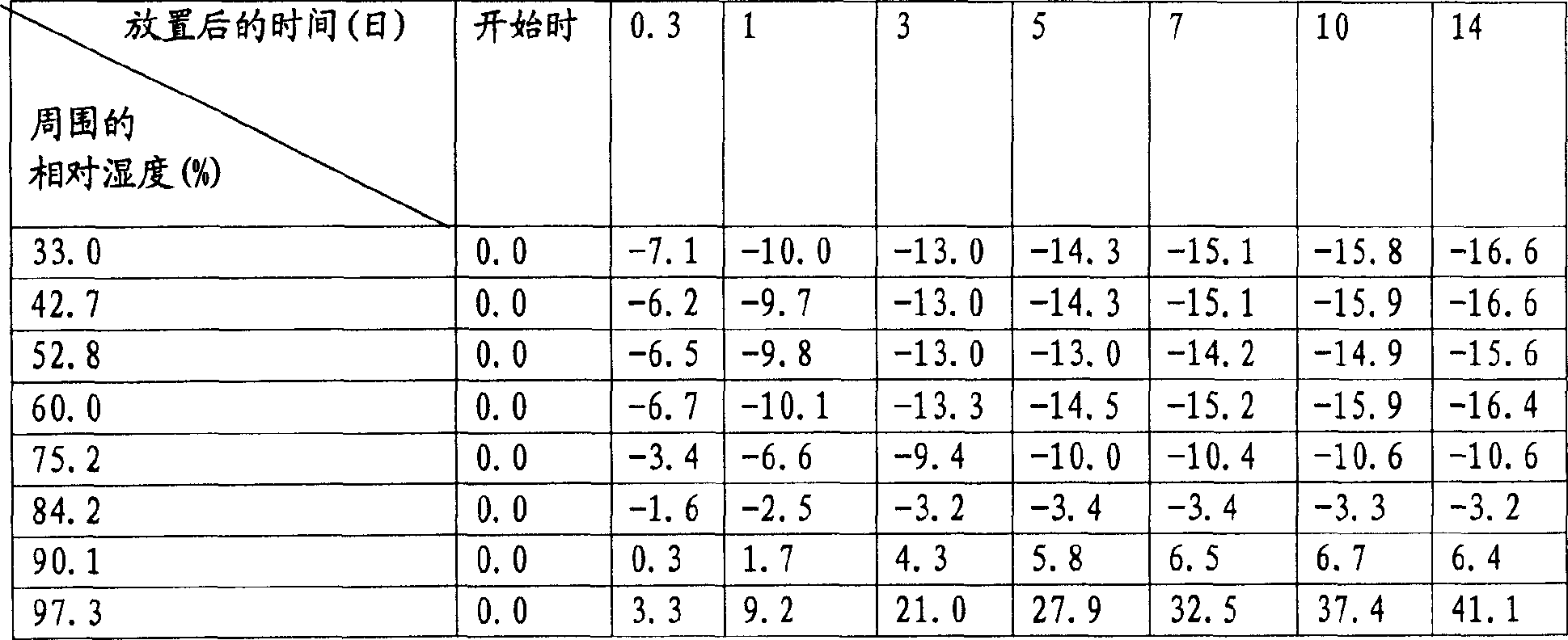

Image

Examples

Embodiment 1

[0084] Calcium carbonate was added to cornstarch milk with a concentration of 20% so that the final concentration became 0.1%, then the pH was adjusted to 6.5, and α-amylase (manufactured by Nobo Corporation, trade name "タ-マミ-ル 60L") was added, And make the content per gram of starch be 0.2%, and react at 95° C. for 15 minutes. Put the reaction solution in an autoclave at 120° C. for 10 minutes, cool it to 50° C., adjust the pH to 5.8, and add the amylase for generating maltotetraose disclosed in JP-A No. 63-240784 (Hayashibara Co., Ltd. Biochemical Research Institute) and isoamylase (manufactured by Hayashibara Biochemical Research Institute of Co., Ltd.), and their contents were 5 units and 500 units per gram of starch, reacted for 48 hours, and then added 30 units per gram of starch Unit α-amylase (manufactured by Ueda Chemical Co., Ltd., trade name "α-amylase 2A") was further reacted at 65° C. for 4 hours. The reaction solution was placed in an autoclave at 120°C for 10 m...

Embodiment 2

[0091] The syrupy moisture fluctuation suppressant obtained by the method of Example 1 was sprayed and dried by a usual method to obtain an amorphous powder moisture fluctuation suppressant. This product has low hygroscopicity and good water solubility, and can be advantageously used as a moisture fluctuation inhibitor in a composition, and has an effect of inhibiting protein modification or lipid oxidation or decomposition during heating or drying, so it is used as a fruit juice or Powdered base agents such as fats and oils are also suitable. In addition, this product can also be used as a vitrification agent and additive for preparations contained in a vitrification composition to increase its glass transition temperature, an anti-caking agent for starch-containing foods, a glazing agent, a coloring agent, Shape-preserving agent, flavor-imparting agent, lipid oxidation and / or decomposition inhibitor, modification inhibitor, pigment anti-discoloration agent, fresh-keeping age...

Embodiment 3

[0093] In order to decolorize the saccharification solution prepared by the method of Example 1 by desalting and refining the H-type and OH-type ion exchange resins, and then further refine it, use a salt-type strongly acidic cation-exchange resin (sold by Dow Chemical Corporation, trade name "Dowex 50W-×4”, Mg ++ type) for column fractionation. Four jacketed stainless steel columns with inner diameters of 5 and 4 cm were filled with resin and connected in series so that the total length of the resin layer was 20 m. While maintaining the temperature inside the column at 55°C, 5v / v% of the sugar solution was added to the resin. Put warm water at 55°C into the resin at SV0.13 for classification, remove the high-content fractions of glucose and maltose, collect the high-content fractions of α,α-trehalose sugar derivatives, further refine and concentrate, and then carry out Spray drying to obtain an amorphous powder moisture fluctuation inhibitor. In terms of anhydrous matter, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com