Rapid efficient method for preparing acrylonitrile polymer

An acrylonitrile and polymer technology, which is applied in the field of rapid and efficient preparation of acrylonitrile polymers, can solve the problems of environmental pollution, slow reaction rate, solvent corrosivity and volatility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

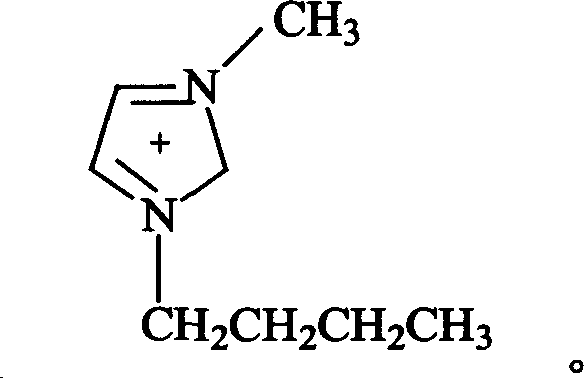

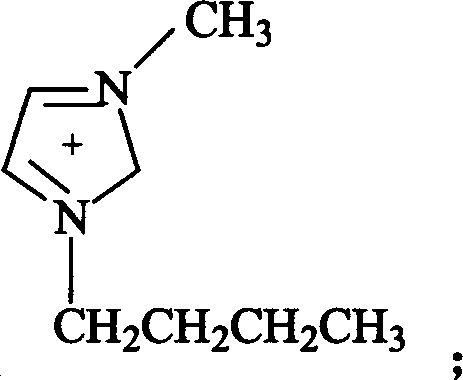

[0019] Take 8 grams [Bmim]BF 4 Ionic liquid, pour the weighed 0.016g initiator azobisisobutyronitrile into it, then add 0.000308mol of itaconic acid, and then add 0.0236mol of acrylonitrile and 0.00256mol of methyl acrylate in sequence. Stop stirring the ionic liquid. After the mixture is uniformly stirred, the mixed ionic liquid is heated to 65° C., and the temperature is maintained for 4 hours to fully polymerize. According to the national standard, the viscosity average molecular weight of the obtained acrylonitrile copolymer is 6.46×10 4 , The conversion rate reached 78%.

Embodiment 2

[0021] Take 8 grams of [Bmim]BF4 ionic liquid, pour in the weighed 0.016 grams of initiator azobisisobutyronitrile, then add 0.000154mol of itaconic acid, and then add 0.0236mol of acrylonitrile and 0.00337mol of acrylic acid in sequence The ionic liquid is constantly agitated while adding the ester. After the mixture is uniformly stirred, the mixed ionic liquid is heated to 70°C, and the temperature is maintained for 1 hour to fully polymerize. According to the national standard, the viscosity average molecular weight of the obtained acrylonitrile copolymer is 5.32×10 4 , The conversion rate reached 80%.

Embodiment 3

[0023] Take 8 grams of [Bmim]BF4 ionic liquid, pour in the weighed 0.016 grams of initiator azobisisobutyronitrile, then add 0.000308mol of itaconic acid, and then add 0.0236mol of acrylonitrile and 0.00256mol of acrylic methyl in sequence The ionic liquid is constantly agitated while adding the ester. After the mixture is uniformly stirred, the mixed ionic liquid is heated to 80°C, and the temperature is maintained for 0.5 hours to fully polymerize. According to the national standard, the viscosity average molecular weight of the obtained acrylonitrile copolymer is 5.32×10 4 , The conversion rate reached 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com