Method and apparatus for treating organic waste

A technology of organic waste and treatment method, applied in the field of comprehensive utilization of resources, can solve the problems of unfermented feed or fertilizer, low utilization rate of waste products, complicated process, etc., to achieve convenient and effective positioning and high waste utilization rate , The effect of simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

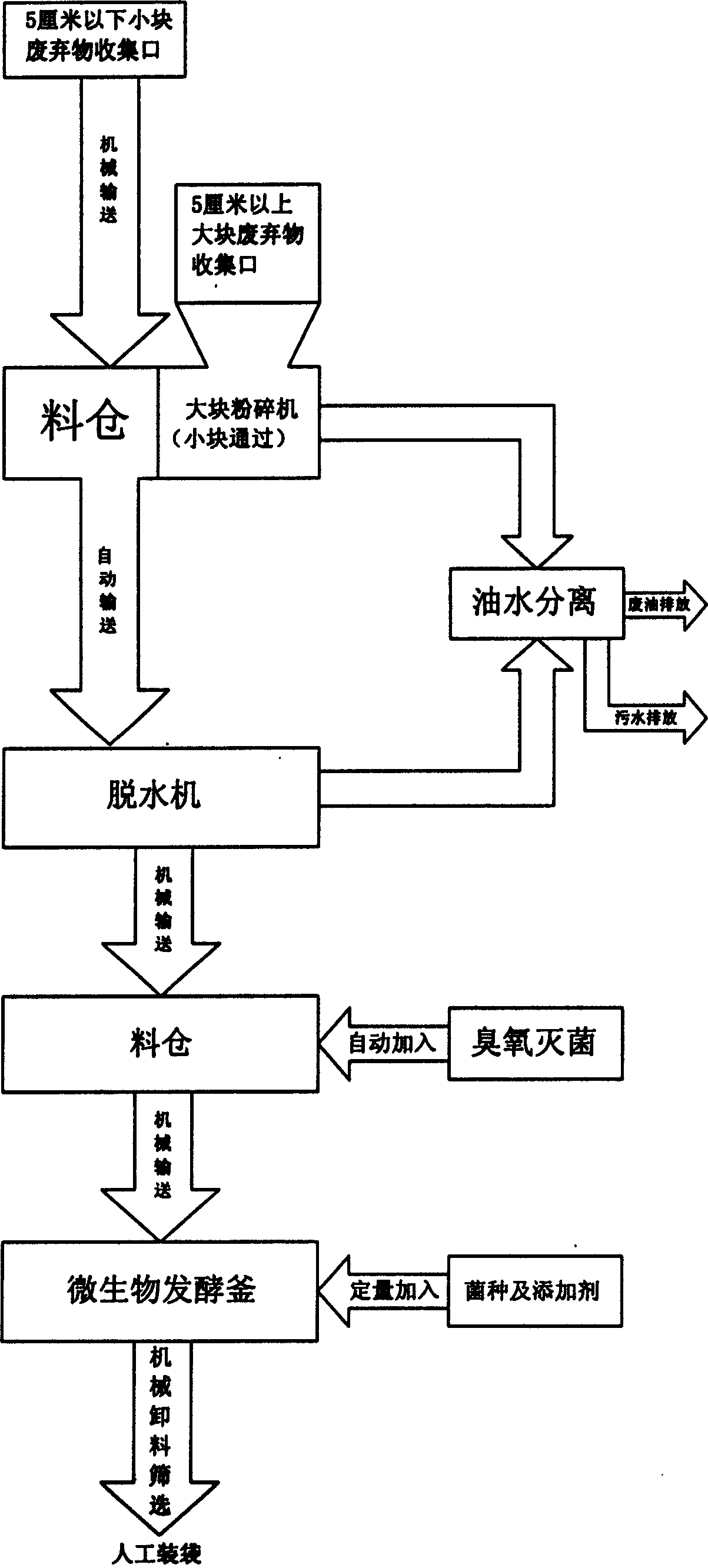

[0066] Refer to attached figure 1 .

[0067] The organic waste treatment method of the present invention utilizes organic waste (kitchen leftovers; food bottom corners, etc.) to collect and concentrate. Crush large pieces and squeeze out excess water. Inoculate microbial feed fermentation strains, rapidly ferment under certain conditions in the biological fermentation tank (period is about 36 hours) to produce animal and vegetable protein, and then add a certain proportion of animal and vegetable protein carriers and other auxiliary materials to become feed with good commercial shape additive. This feed additive can also add corresponding ingredients according to different needs. Organic waste treatment methods include waste collection, draining and oil draining, and sterilization treatment. The specific process is as follows:

[0068] 1. Collection and transportation of organic waste (kitchen leftovers)

[0069] Collect kitchen leftovers and organic waste at the lower co...

Embodiment 2

[0092] Refer to attached figure 1 .

[0093] The organic waste treatment method uses organic waste (kitchen leftovers; food corners, etc.) to collect and concentrate. Crush large pieces and squeeze out excess water. Inoculate microbial fertilizer fermentation strains, quickly ferment in a biological fermentation tank (period of about 48 hours) to become a decomposed organic fertilizer, and then mix a certain proportion of nitrogen, phosphorus, and potassium fertilizers to become an organic compound fertilizer with a good commercial shape ; Or mixed with nitrogen-fixing, phosphorus-dissolving, potassium-dissolving functional bacterial fertilizers to become organic biological compound fertilizers. Different special fertilizer formulas are designed according to different soils and different crops, which can be applied to various types of soil and crops. Integration with soil testing and formula fertilization technology can make special fertilizers more targeted. Organic waste...

Embodiment 3

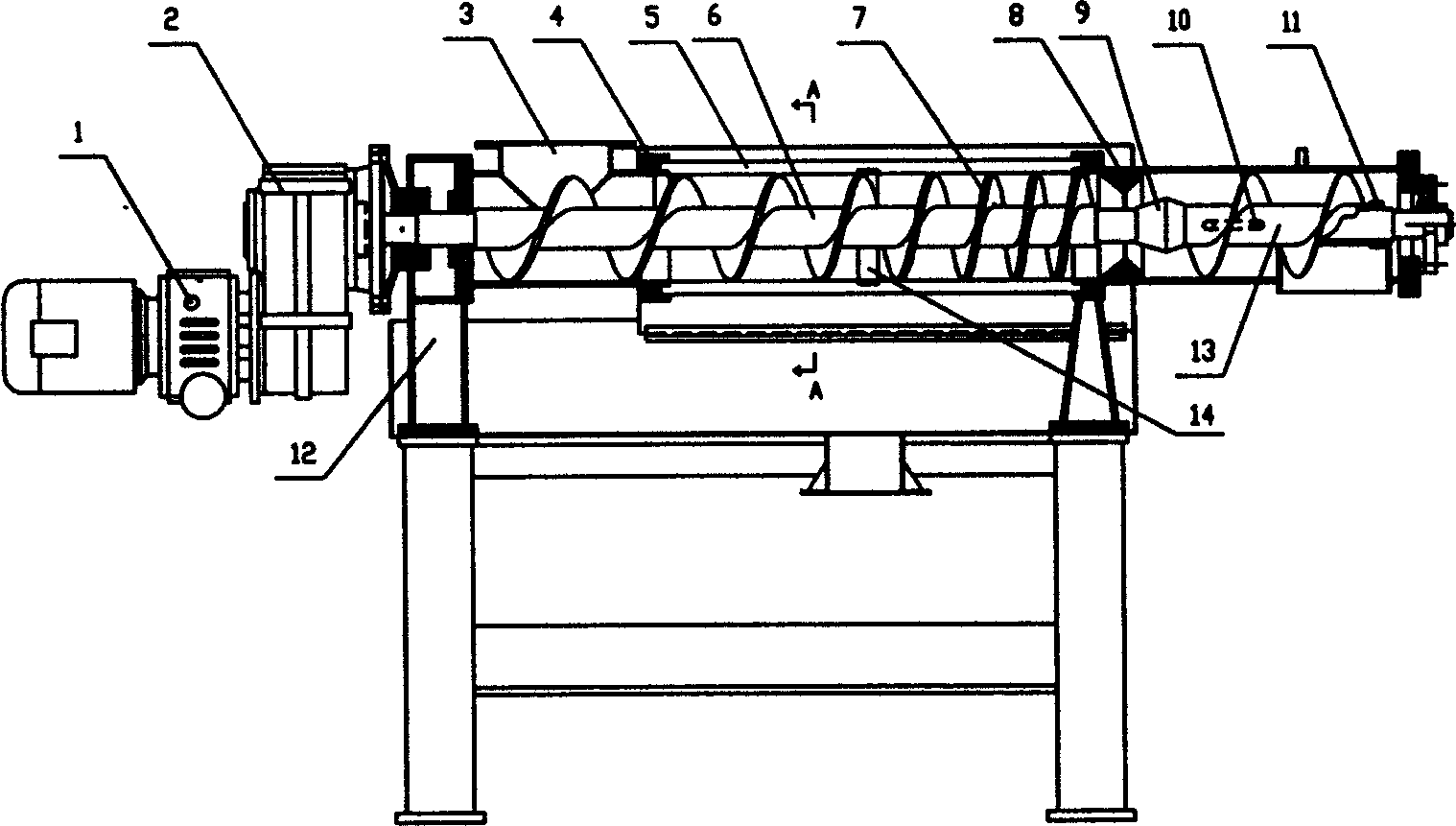

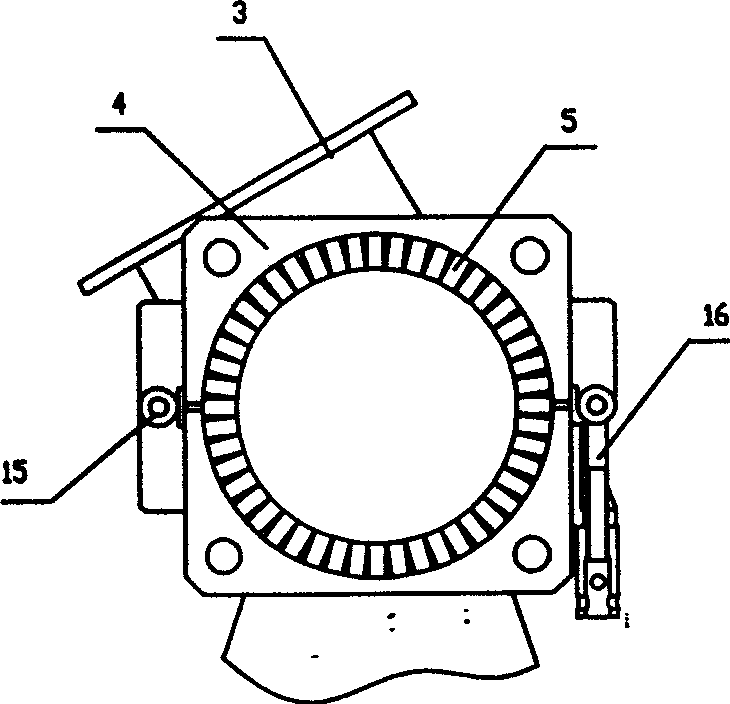

[0103] Refer to attached figure 2 , image 3 and Figure 4 .

[0104]The organic matter dehydration press includes a drive motor 1, a reducer 2, and the drive motor 1 drives a screw 7 through the reducer 2. The helix 7 is assembled on the bearing support 12, and is a helix structure with a pitch shrinkage. The outside of the spiral body 7 is a cylindrical structure composed of grid bars 5 . The port of the pressing screw body 7 is a conical structure, and the conical surface 8 is matched with the shaft conical surface 9 to form an organic material extrusion port. The coaxial conical surface 9 is the conical surface of the coaxial sleeve 13 assembled on the drive shaft 6 . The coaxial sleeve 13 is assembled on the rotating shaft 6 through the pin 10 and the adjusting nut 11 . Adjusting the nut 11 makes the coaxial sleeve 13 move through the pin 10, thereby changing the distance between the conical port of the spiral body and the coaxial conical surface 9 to change the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com