Method for preparing nano-tubular sodium titanate/titanci acid

A technology of nanotubes and sodium titanate, applied in the field of sodium titanate and titanic acid, can solve the problems of difficult to achieve high temperature and high pressure conditions, restrict industrial production, long reaction time, etc., and achieve good ion exchange performance, good economic benefits and social benefits. Benefit, effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

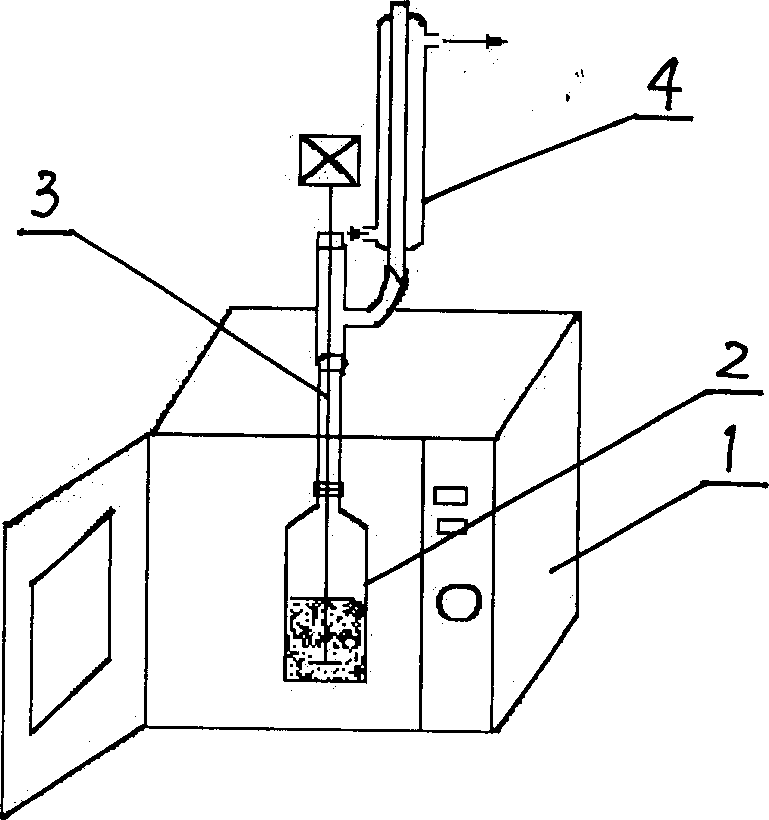

Method used

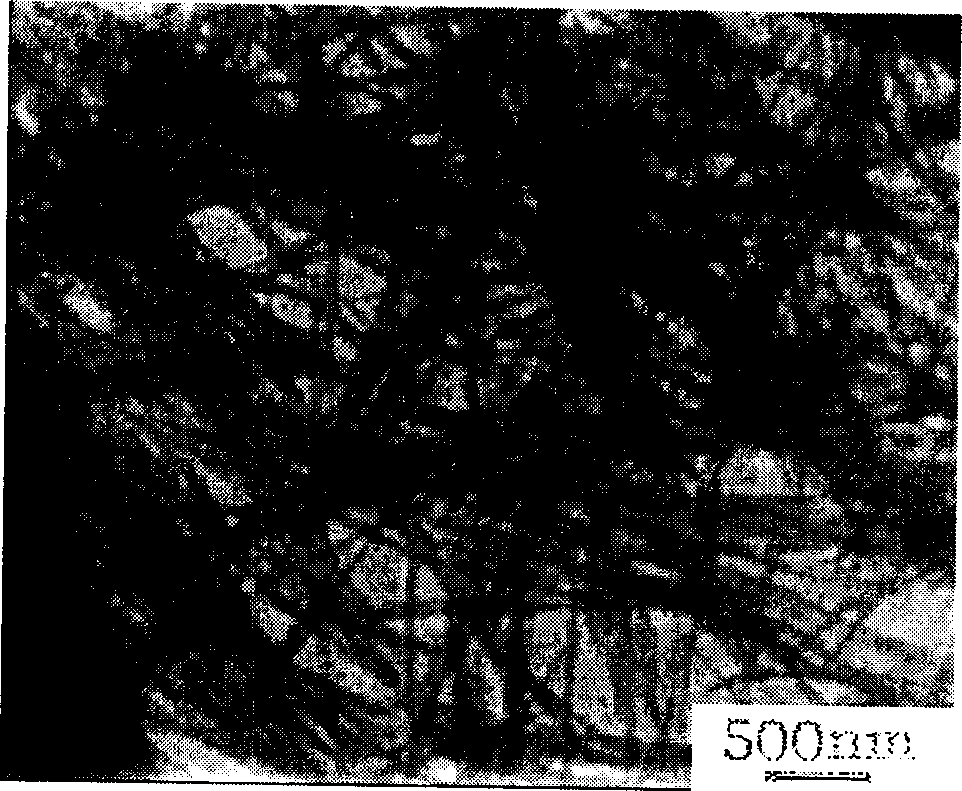

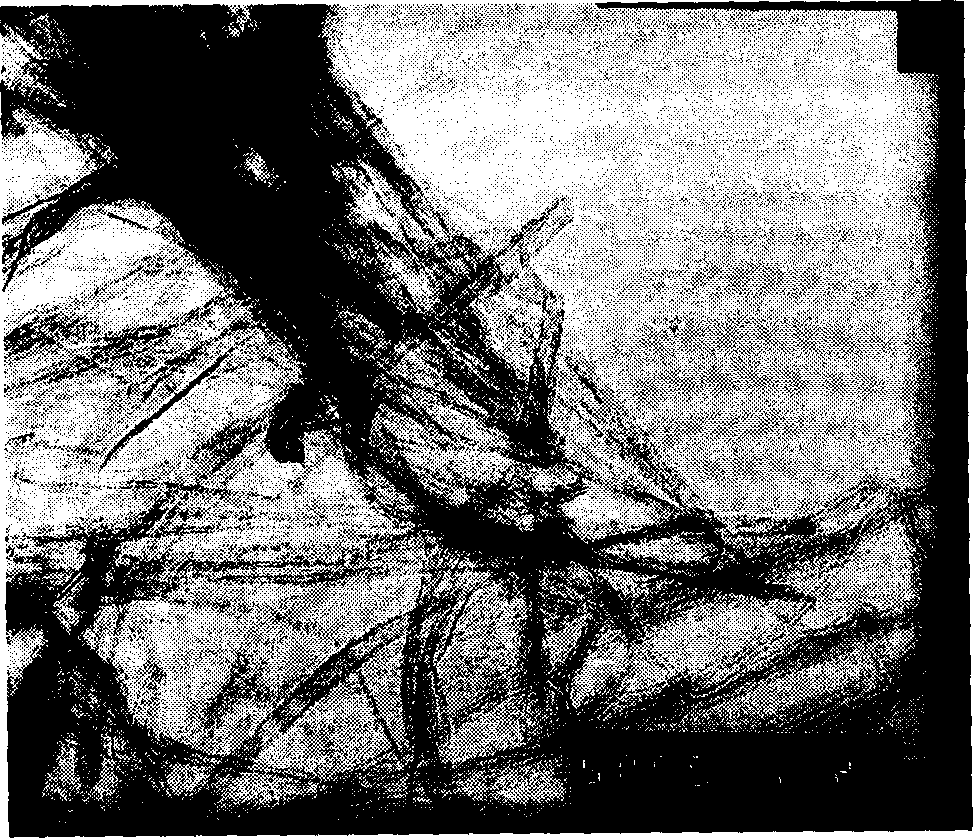

Image

Examples

Embodiment 1

[0019] Embodiment 1, get 5g TiO 2 (anatase titanium dioxide powder produced by Zhoushan Tomorrow Chemical Plant), slowly add the polytetrafluoroethylene container that fills 100ml concentration and be the NaOH solution of 40% (weight percentage concentration), place in microwave oven, be set to medium low heat (750W , work for 10s, stop for 12s) Stir with a mechanical stirrer, add a reflux condenser, react for 6 hours, cool and settle, pour out the supernatant, wash with distilled water until the pH value is 6.0-8.0, filter, and dry to obtain nano The tube sodium titanate product is then soaked in 0.1M hydrochloric acid for 8 hours, filtered, washed, and dried to obtain the nanotube titanate product.

Embodiment 2

[0020] Embodiment 2, take 5g of metatitanic acid slurry with a water content of 50%, slowly add it into a polytetrafluoroethylene container filled with 100ml of NaOH solution with a concentration of 40% (weight fraction), place it in a microwave oven, set it to medium-low Fire (same as above), stir with a mechanical stirrer, add a reflux condenser, react for 6 hours, cool and settle, pour out the supernatant, wash with distilled water until the pH value is 6.0-8.0, filter, and dry to obtain titanium nanotubes Sodium acid product, then soaked in 0.1M hydrochloric acid for 8 hours, filtered, washed, and dried to obtain nanotube titanic acid product.

Embodiment 3

[0021] Embodiment 3, get reagent grade TiO 2 1g, slowly add 100ml of NaOH solution with a concentration of 40% (weight fraction) into a polytetrafluoroethylene container, place it in a microwave oven, set it to medium heat (750W, work for 12s, stop for 10s), stir with a mechanical stirrer , and add a reflux condenser, react for 6 hours, cool and settle, pour out the supernatant, wash with distilled water until the pH value is 6.0-8.0, filter, and dry to obtain the nanotube sodium titanate product, and then use 0.1M hydrochloric acid Soak for 8 hours, filter, wash and dry to obtain the nanotube titanic acid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com