Multilayer sheet type ZnO piezoresistor prepared by chemical method synthesis oxide powder and its manufacturing method

A technology of varistor and oxide powder, applied in varistor core, resistor manufacturing, varistor and other directions, can solve the problems of increased cost, high rejection rate, poor mixing uniformity of added elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

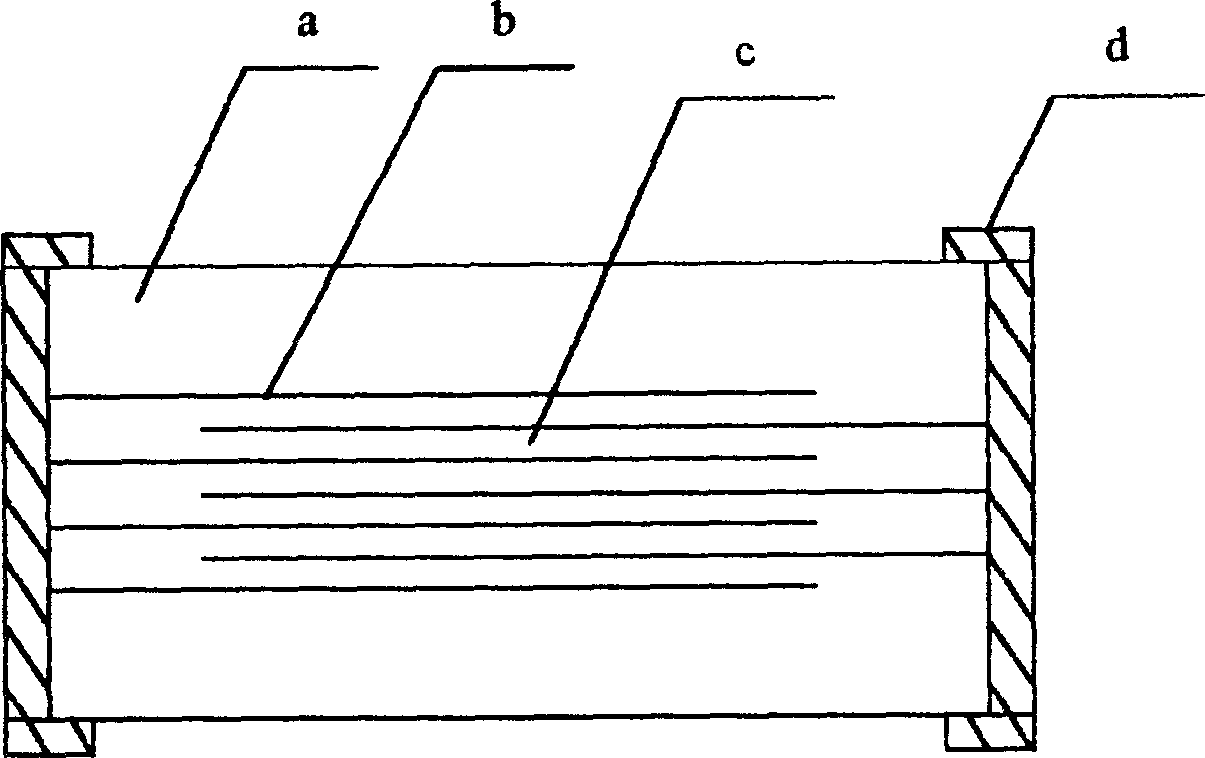

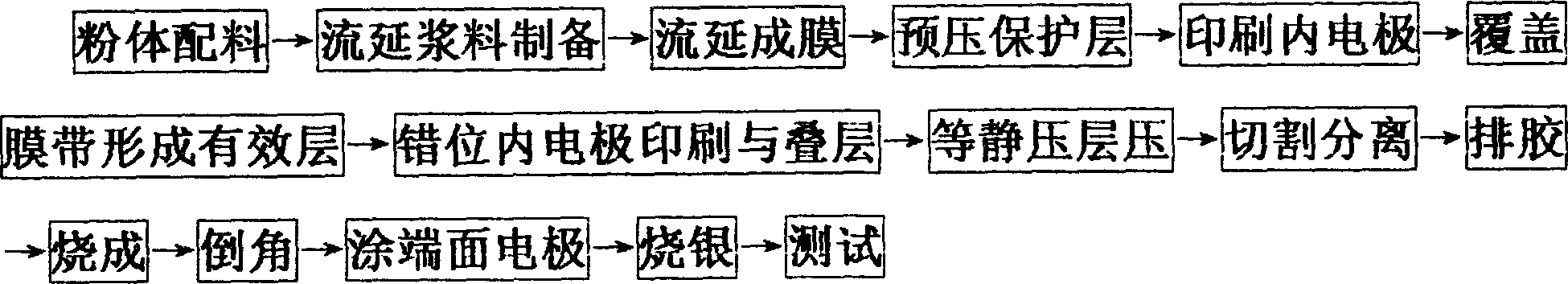

[0060] Prepare a 1mol / L additive mixed metal salt solution containing Bi, Sb, Mn, Si, Cr, Co, Ni, Al and other elements according to the ratio in the formula table 1. After fully stirring at 50°C, use the reverse feeding method to add NH 4 HCO 3 -NH 3 ·H 2 O-NH 4 The Ac composite precipitant realizes co-precipitation at a certain pH value. The obtained precipitate is added with an appropriate dispersant, filtered, thoroughly washed, dried at a constant temperature of 110°C, and calcined at 500-700°C for 2.5h to obtain a composite oxide additive powder. Such as figure 1 structure shown, figure 2 The manufacturing method flow shown, and according to the formula table 1, accurately weigh the ZnO powder and the composite oxide additive powder synthesized by chemical method. Put the weighed material into a ball mill and add an appropriate amount of xylene, binder, dispersant and zirconium balls, ball mill for 12 hours to obtain a cast slurry, and then cast a ceramic film tap...

Embodiment 2

[0063] Prepare 1mol / L additive mixed metal ion solution containing Bi, Sb, Mn, Cr, Co and other elements according to the ratio in formula table 2, adjust the pH value of the solution to make a sol, shrink into a gel after aging, and extract After filtering, washing with distilled water and absolute ethanol, drying at 120°C for 2h, and calcining at 500-700°C for 2.5h to obtain the composite oxide additive powder. Such as figure 1 structure shown, figure 2 The manufacturing method flow shown, and according to the formula table 2, accurately weigh the ZnO powder and the compound oxide additive powder synthesized by chemical method, put the weighed material into the ball mill and add appropriate amount of xylene and binder , dispersant and zirconium balls, ball milled for 12 hours to obtain casting slurry, and then cast a ceramic film tape with a thickness of 25 microns, and ten layers of ceramic film tapes are slightly pressed to obtain a film tape with a thickness of about 25...

Embodiment 3

[0066] Prepare 1 mol / L compound oxide mixed metal salt solution containing Zn, Bi, Sb, Mn, Si, Cr, Co, Ni, Al and other elements according to the chemical composition specified in formula table 3, and fully stir at 50°C , using the reverse addition method with NH 4 HCO 3 -NH 3 ·H 2 O-NH 4 The Ac composite precipitant realizes co-precipitation at a certain pH value. Add appropriate dispersant to the obtained precipitate, filter it, thoroughly wash and dry at 110°C, and calcinate at 500-700°C for 2.5h to obtain chemically synthesized compound containing Zn, Bi, Sb, Mn, Si, Cr, Co, Ni , Al and other elements of composite oxide powder. Such as figure 1 structure shown, figure 2The manufacturing method flow shown is to accurately weigh the chemically synthesized composite oxide powder containing Zn and Bi, Sb, Mn, Si, Cr, Co, Ni, Al and other elements, put the weighed material into the ball mill and add An appropriate amount of xylene, binder, dispersant and zirconium ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com