Powder for preparing porous material by laser synthesis reaction

A porous material, laser synthesis technology, used in powder coatings, devices for coating liquids on surfaces, coatings, etc. The problem of poor strength and fracture toughness can make up for the difficulty of bearing large loads, solve the problem of mechanical compatibility, and overcome the poor strength and fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

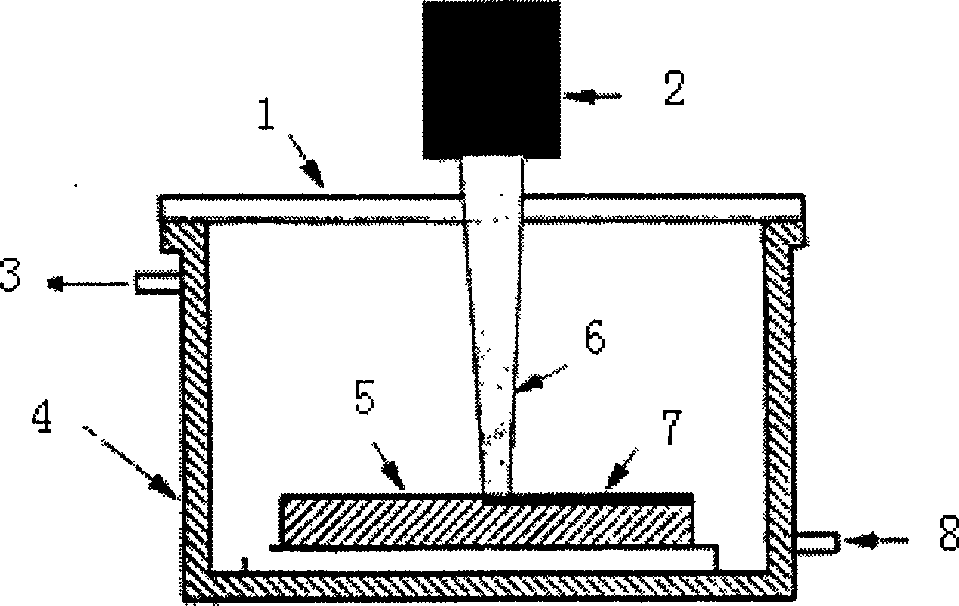

Method used

Image

Examples

Embodiment 1

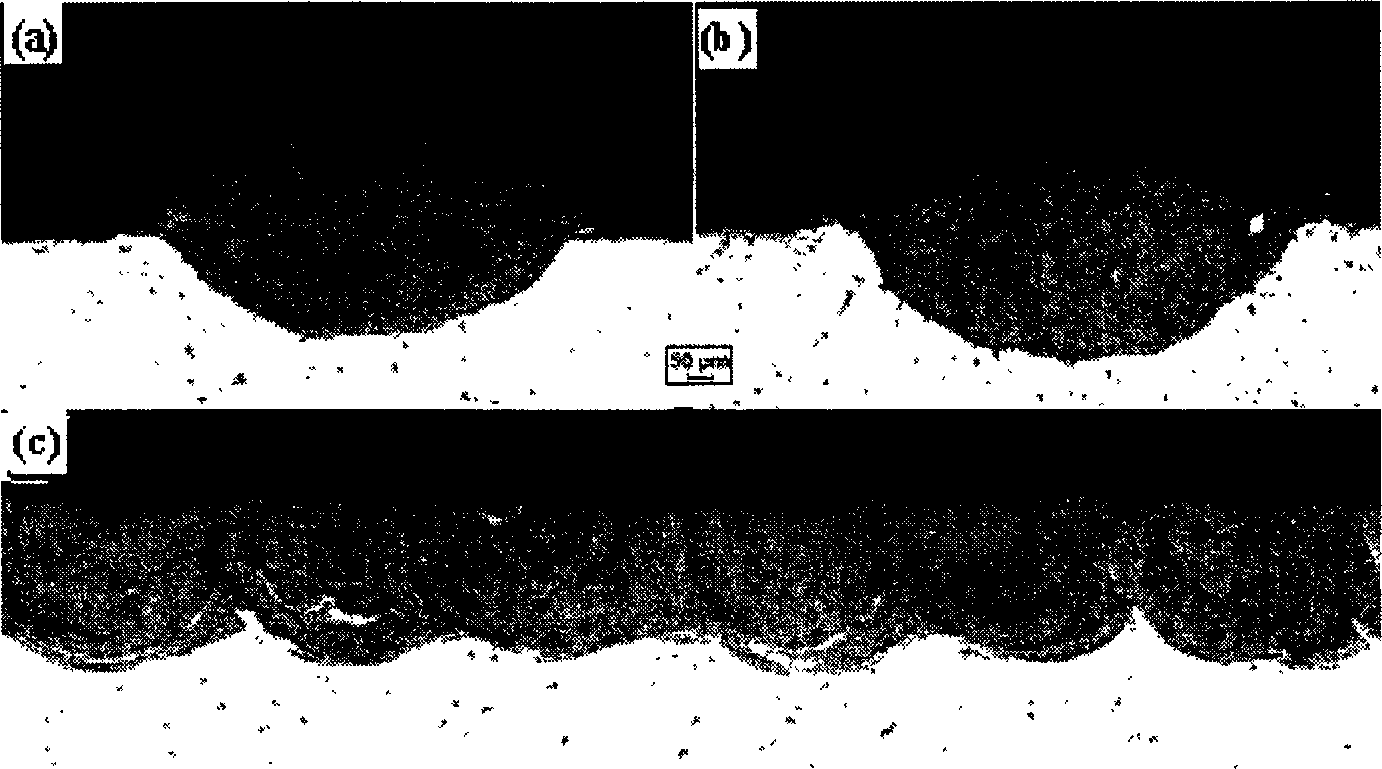

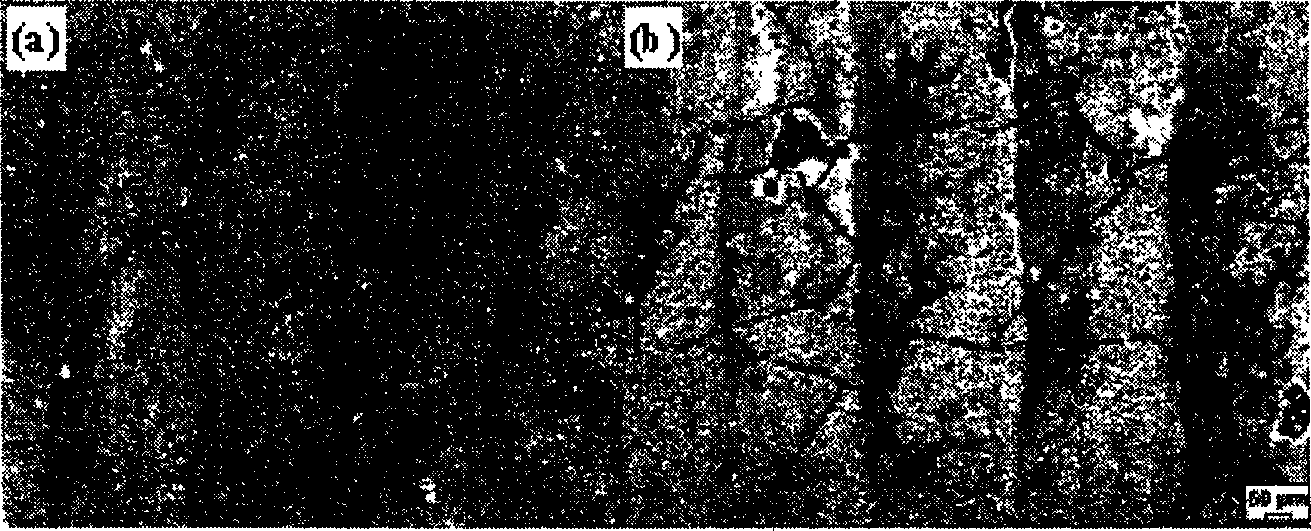

[0069] Grind the 10mm×10mm×5mm NiTi substrate and the surface to be observed of the porous coating sample to a metallographic sample, wash and dry it with deionized water, and place it in a reagent bottle filled with 200mL, 37°C simulated human body fluid SBF solution After soaking, the SBF solution in the bottle is replaced every 2 days to keep the composition of the SBF soaking solution basically constant. The two samples soaked in the SBF solution were taken out at the same time regularly, washed with deionized water, and dried at 50°C. SEM-EDX was used to observe and analyze the deposition and composition of bone-like apatite on the surface of the sample, and Nicolet Fourier transform infrared Spectroscopic (FTIR) analysis of the chemical structure of the sediment.

[0070] The formation of bone-like apatite on biomaterials is a prerequisite for its osteoinductivity. Therefore, studying the factors that affect the formation of bone-like apatite in implant materials is an e...

Embodiment 2

[0073] Animal implantation experiments. The animals selected for the experiment were 2 18-month-old male rabbits with body weights of 6.5Kg and 6.3Kg respectively. Animals were fasted the night before surgery and water was deprived on the same day. Pentobarbital sodium narcotics were injected through the ear according to conventional methods, and routine disinfection was performed. According to previous research experience, the implantation site of the implant material affects the bone formation in the body. In order to successfully induce the production of bone cells, the muscles near the vertebrae of the back were selected as the implantation site. An incision about 8 cm long was made on the back of the rabbit, the skin and subcutaneous tissue were cut open, the muscle tissue was exposed, and the intermuscular space was separated. Two samples of NiTi alloy dense material and porous coating were implanted into the rabbit's back spine in groups. There were 8 parallel samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com