Preparation method of multi-kind micro-element injection

A trace element and injection technology, which is applied in the field of preparation of various trace element injections, can solve the problems of strong irritation, decreased content, poor product stability, etc., and achieves reduction of related substances, reduced irritation, and increased stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

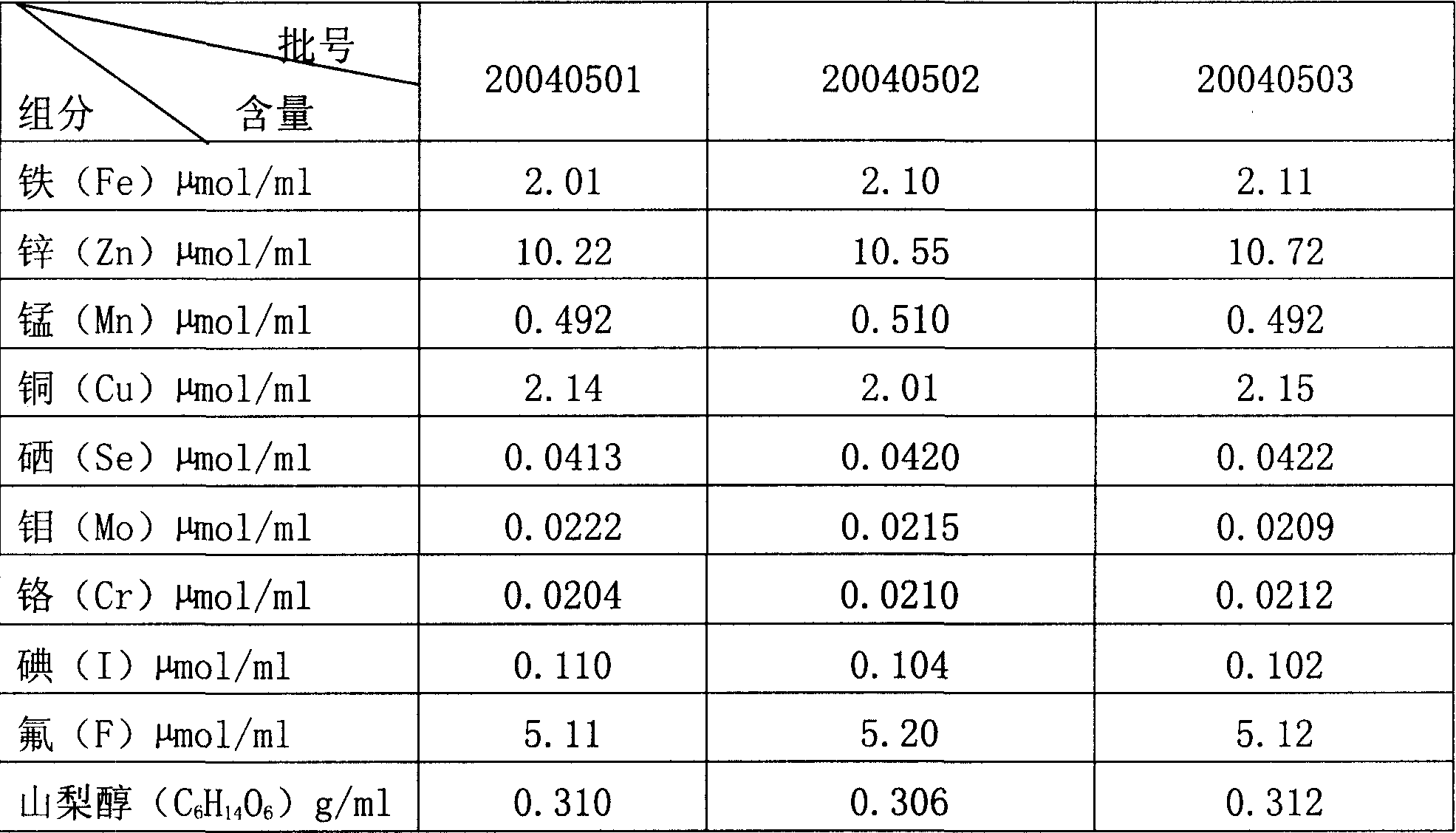

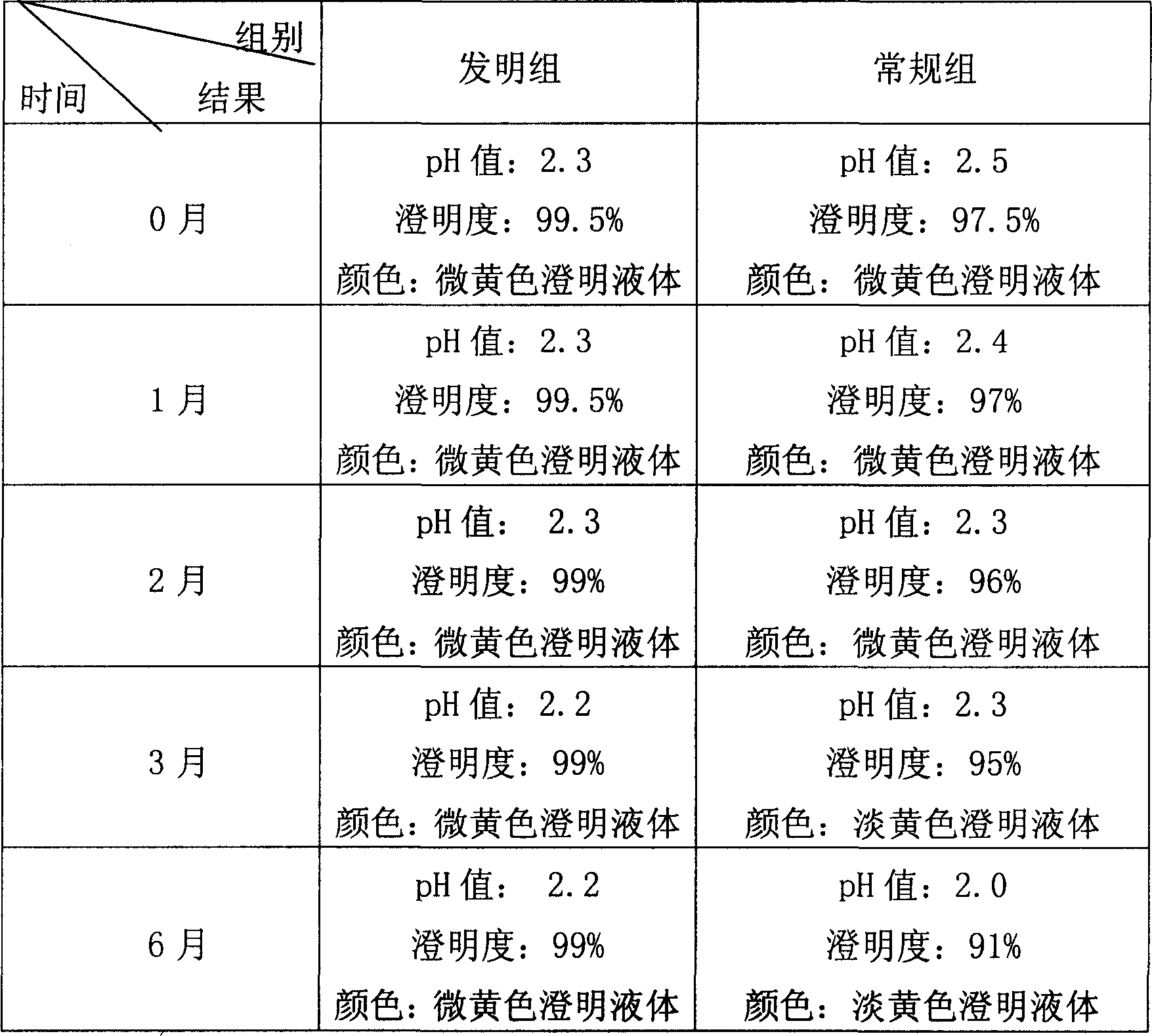

Method used

Image

Examples

Embodiment 1

[0029] A) Take fresh water for injection with a preparation amount of 15% at 80°C, cool down to 25°C, add chromium chloride, ferric chloride, zinc chloride, copper chloride, and manganese chloride in the prescription in order, and stir well, Ultrasonic treatment for 15 minutes, shading and sealing, refrigerating at 8°C for 24 hours, ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 100,000, and ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 10,000 to obtain ultrafiltrate I.

[0030] B) Take fresh water for injection with a preparation volume of 10% at 90°C, lower the temperature to 25°C, add sodium molybdate and sodium selenite in the prescription in sequence, stir well, ultrasonicate for 20 minutes, shading and airtight, and refrigerate at 5°C After 24 hours, ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 100,000, and then ultrafiltration with an ultrafiltration membrane...

Embodiment 2

[0035] A) Take fresh water for injection with a preparation amount of 20% at 85°C, cool down to 30°C, add chromium chloride, ferric chloride, zinc chloride, copper chloride, and manganese chloride in the prescription in order, and stir well, Ultrasonic treatment for 20 minutes, shading and sealing, refrigerated at 5°C for 12 hours, ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 100,000, and ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 10,000 to obtain ultrafiltrate I.

[0036]B) Take fresh water for injection with a preparation volume of 15% at 90°C, lower the temperature to 30°C, add sodium molybdate and sodium selenite in the prescription in sequence, stir well, ultrasonicate for 20 minutes, shading and airtight, and refrigerate at 10°C After 24 hours, ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 100,000, and then ultrafiltration with an ultrafiltration membrane ...

Embodiment 3

[0041] A) Take fresh water for injection with a preparation amount of 25% at 90°C, cool down to 20°C, add chromium chloride, ferric chloride, zinc chloride, copper chloride, and manganese chloride in the prescription in order, and stir well, Ultrasonic treatment for 25 minutes, shading and sealing, refrigerating at 7°C for 36 hours, ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 100,000, and ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 10,000 to obtain ultrafiltrate I.

[0042] B) Take fresh water for injection with a preparation amount of 5% at 85°C, cool down to 20°C, add sodium molybdate and sodium selenite in the prescription in sequence, stir well, ultrasonicate for 15 minutes, shading and airtight, and refrigerate at 5°C After 12 hours, ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 100,000, and then ultrafiltration with an ultrafiltration membrane with a molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com