Radiant energy photocatalysis combiner

A photocatalyst and radiant energy technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as affecting reaction efficiency, cost, and difficulty in forming a dispersed state.

- Summary

- Abstract

- Description

- Claims

- Application Information

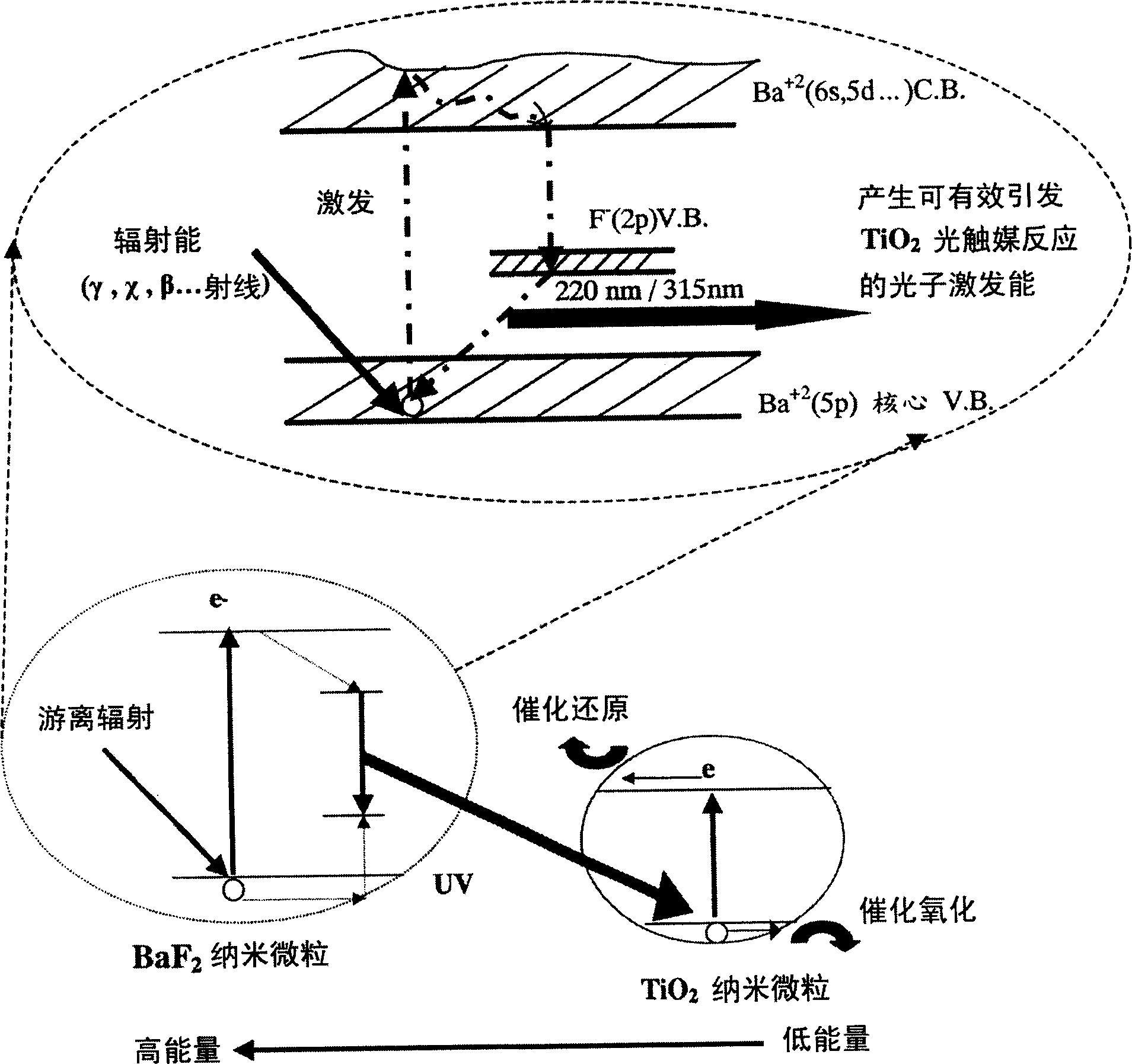

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

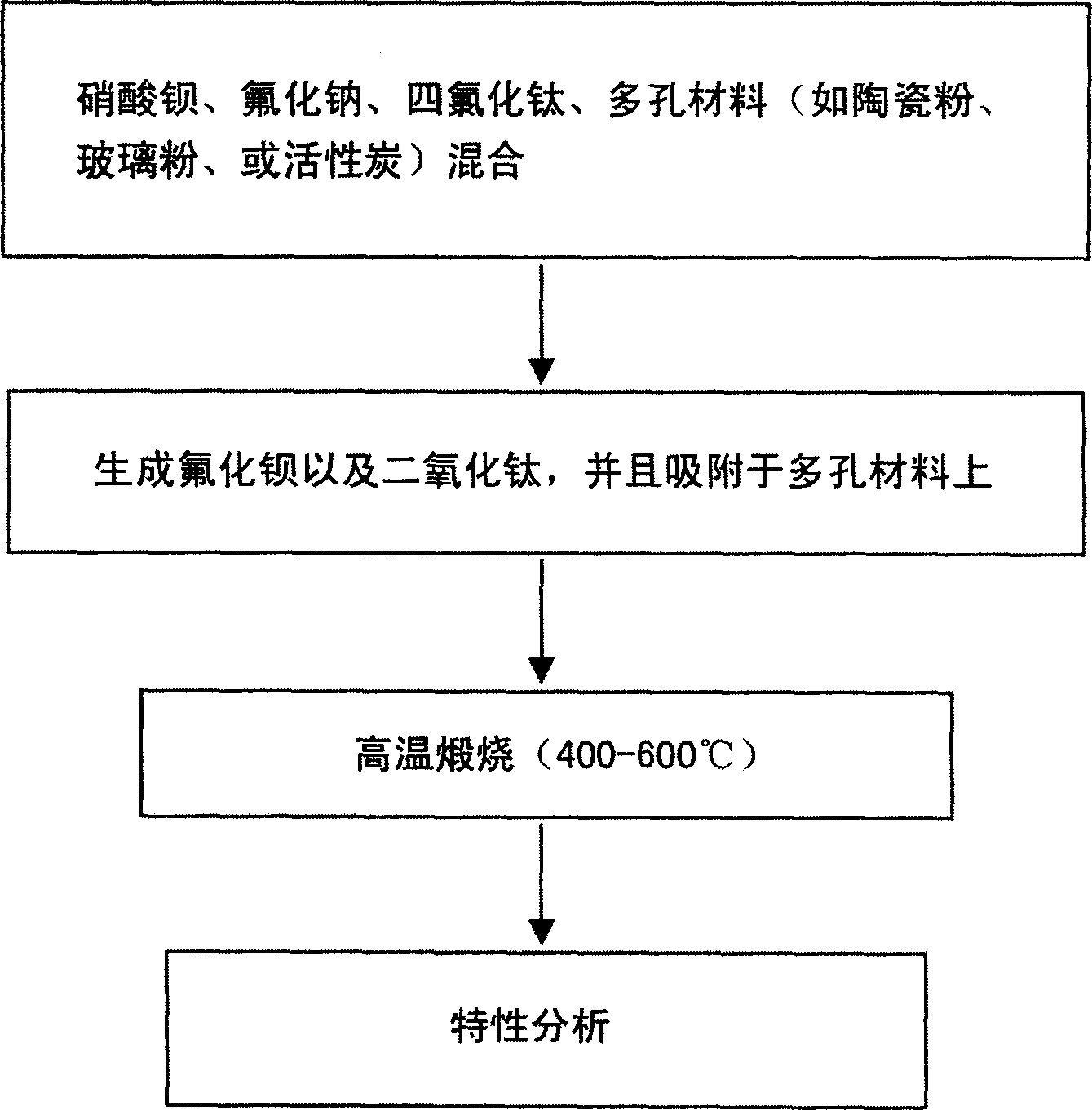

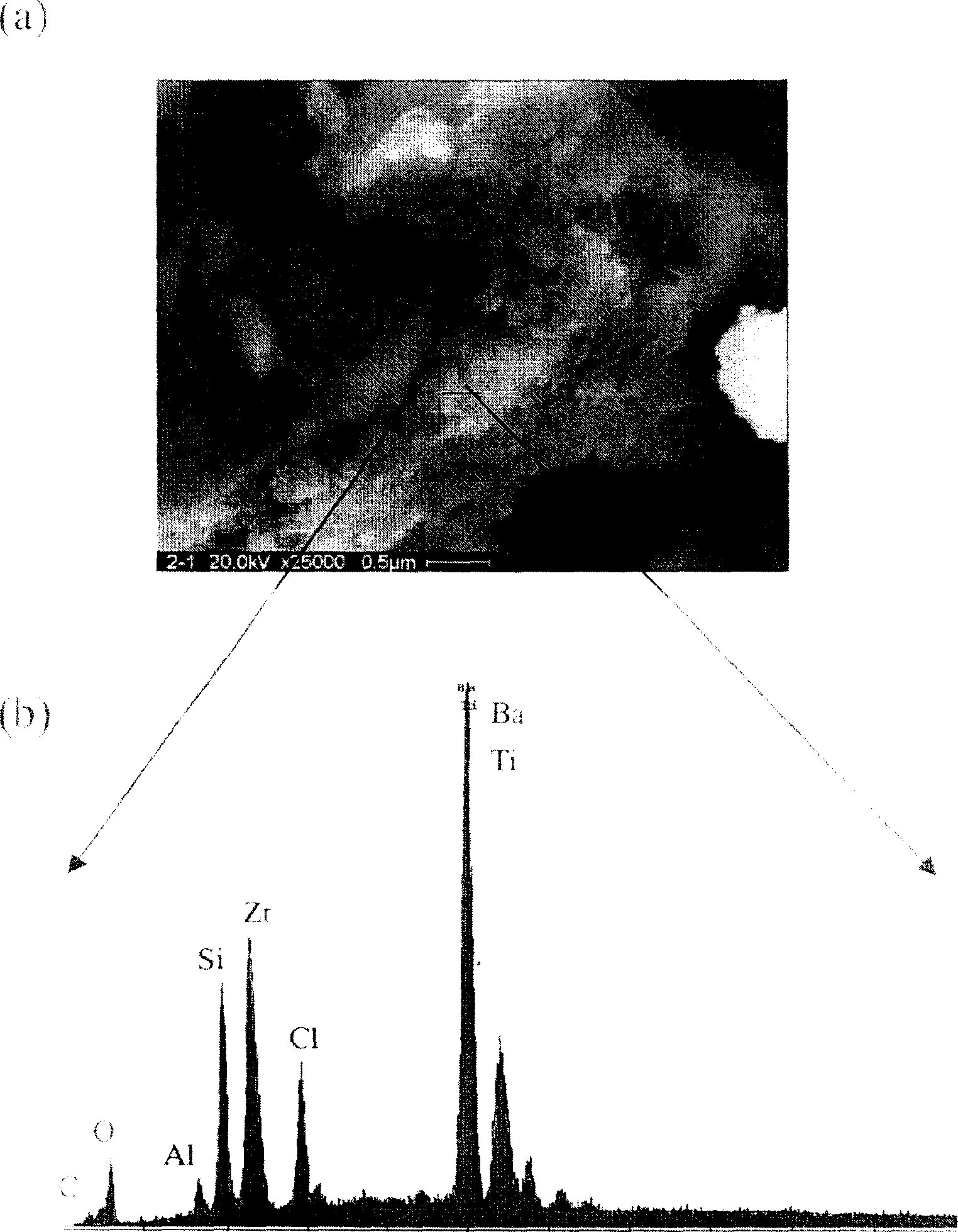

[0028] Embodiment 1. The preparation of radiation energy effect type photocatalyst complex

[0029] Add an appropriate amount of EDTA to the alkaline aqueous solution at room temperature, add barium nitrate and sodium fluoride and dissolve them, add quantitative ceramic powder and other powders, and after uniform stirring, add titanium tetrachloride drop by drop and stir for about 2 hours. Secondly, after the solution is evaporated to dryness by using a heat source, the powder is dried in an oven and calcined at a high temperature of about 400°C to obtain the photocatalyst powder. The mixing weight ratio (in gram) of each reactant such as above-mentioned barium nitrate, sodium fluoride, titanium tetrachloride and porous material (ceramic powder, glass powder or active carbon) is respectively 1~5: 0.7~1.8: 0.4~2.0: 2~7, and the number of moles of EDTA is the sum of the number of moles of barium nitrate and titanium tetrachloride. After the reaction is completed, the barium flu...

Embodiment 2

[0032] Embodiment 2. carry out photocatalyst reaction with radiation energy effect type photocatalyst complex

[0033] Prepare 6 groups of methylene blue solutions with a concentration of 10ppm, add 0.2 g of the photocatalyst complex (C1-C6) prepared in Example 1 into the methylene blue solution, and irradiate with the Co-60 gamma radiation source of 25Gy . Since methylene blue has a very large and sensitive absorption peak at a wavelength of about 663nm in the visible light range, the change in the intensity of the absorption peak here can be measured by a photoelectric colorimeter. In addition, the methylene blue solution is blue in the oxidized state and colorless in the reduced state, so the color change of the solution can be easily checked with the naked eye to judge whether the solution sample has undergone redox reaction.

[0034] The apparatus for carrying out the reaction can be as Figure 4 As shown, the target object to be treated (such as waste resin or industri...

Embodiment 3

[0038] Embodiment 3. Decompose organic matter with radiation energy effect type photocatalyst complex

[0039] The reaction device is as described in Example 2, except that the processed target is changed to the Purolite company cation exchange resin actually used by Taiwan Nuclear Power Plant. With 1 gram of resin, 1 gram of C6 photocatalyst complex (preparation method is as embodiment 1), the water of 70ml and containing activity 5 * 10 6 Bq's Co-60 placement Figure 4 In the reaction vessel, the maximum absorbed dose rate of the solution is about 4mGy / h. Tests were carried out with different irradiation doses, and the total carbon (TOC) content after irradiation was measured with an elemental analyzer. The results are shown in Table 4. The irradiation dose of 1-9Gy can decompose the resin. As the irradiation dose increases, the resin gradually changes from granular to powder, and finally becomes small molecules in the solution. The irradiation dose listed in Table 4 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com