Method for production of enzyme granules and enzyme granules produced thus

A technology of enzyme granules and granules, applied in biochemical equipment and methods, food preparation, enzymes, etc., can solve the problems of no longer controllable residence time, achieve the effect of increasing yield and avoiding unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

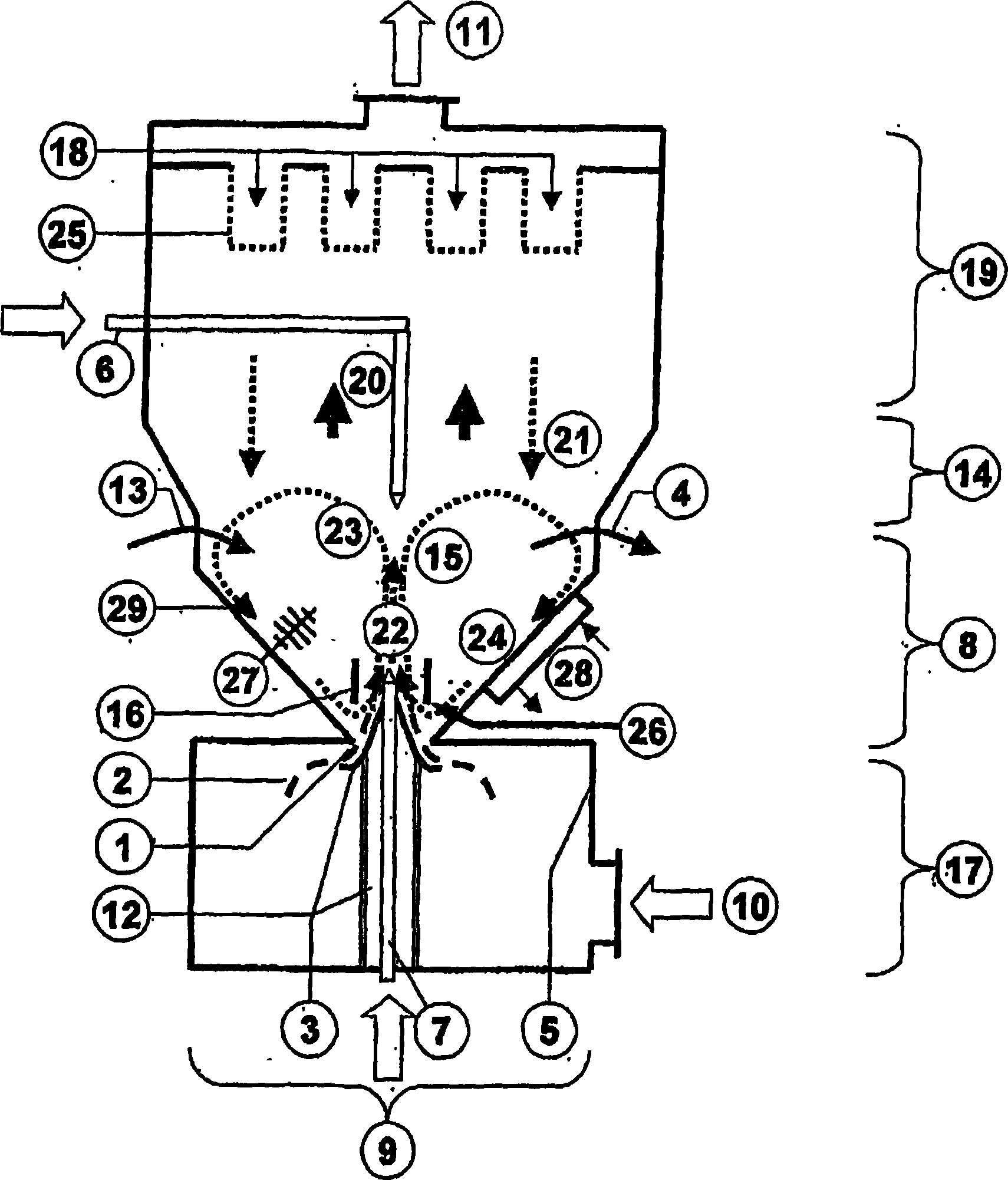

[0043] Embodiment 1: preparation enzyme granule

[0044] An enzyme preparation is sprayed into the device characterized by the above-mentioned structure. The enzyme preparation additionally contains stabilizers and binder components in the enzyme solution, and has a final concentration of solid matter of about 22 mass percent. The process chamber is characterized by a rectangular cross-section and has 0.15 x 0.2 = 0.03 m above the sloped side walls 2The cross-sectional area and the height of about 1m. A process air flow of approximately 180 kg / h heated to approximately 140° C. is conveyed via 2 gas supply gaps distributed longitudinally through the device. The liquid formulation was sprayed into a process air jet with a flow rate of about 50 g / min through a vertically upward-spraying two-component nozzle supplied with compressed air. About 500 g of enzyme granules are in the process chamber. The process air is cooled by the evaporation process and leaves the unit at about 4...

Embodiment 2

[0051] Example 2: Enzyme granules with phytase from Aspergillus niger:

[0052] Commercially available phytase (Natuphos 5000L, BASF, Ludwigshafen, Deutschland) was dialyzed to remove preservatives and salts using demineralized water and ultrafilters with a porosity that would not allow the enzyme to pass through. The enzyme is then ultrafiltered to obtain a high-concentration liquid enzyme preparation.

[0053] Polyvinyl alcohol as binder was added to 25% by weight of this liquid enzyme preparation with a phytase-activity of 24000 FTU / g and a dry content of 25% by weight. The remaining 75% by weight solution was spray-dried in the apparatus described in Example 1 with an air inlet temperature of 180°C and an exhaust temperature of 70°C.

[0054] Pack the spray-dried enzyme powder into a dust-proof docking container. It yields an enzyme powder with 90000 FTU / g phytase-activity and 95% dry matter. The container with the spray-dried enzyme powder is docked with the dust-proof...

Embodiment 3

[0057] Example 3: Application of the salt- / binder solution

[0058] A pilot plant with 4 inlet chambers and 4 nozzles was used. Proteases are used as enzymes. Inorganic alkali metal salts and customary binders are used as salt / binder components. The portion of the ingredient is expressed in % by weight ("%").

[0059] Enzyme solution (cold)

Salt-binder suspension

room

3

1

concentration

%

18

50

Spray amount

kg / h

22

12

water per nozzle

kg / h

6.0

6

share in the product

%

39.8

60.2

Intake air temperature

℃

125

Exhaust gas temperature

℃

55

[0060] Enzyme part

salt + binder part

room

4

share in solution

%

10

24

Spray amount

kg / h

30

water per nozzle

kg / h

4.95 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com